Disc winding

一种盘形绕组、筒形绕组的技术,应用在半匝盘领域,能够解决不能用半匝盘的绕组等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

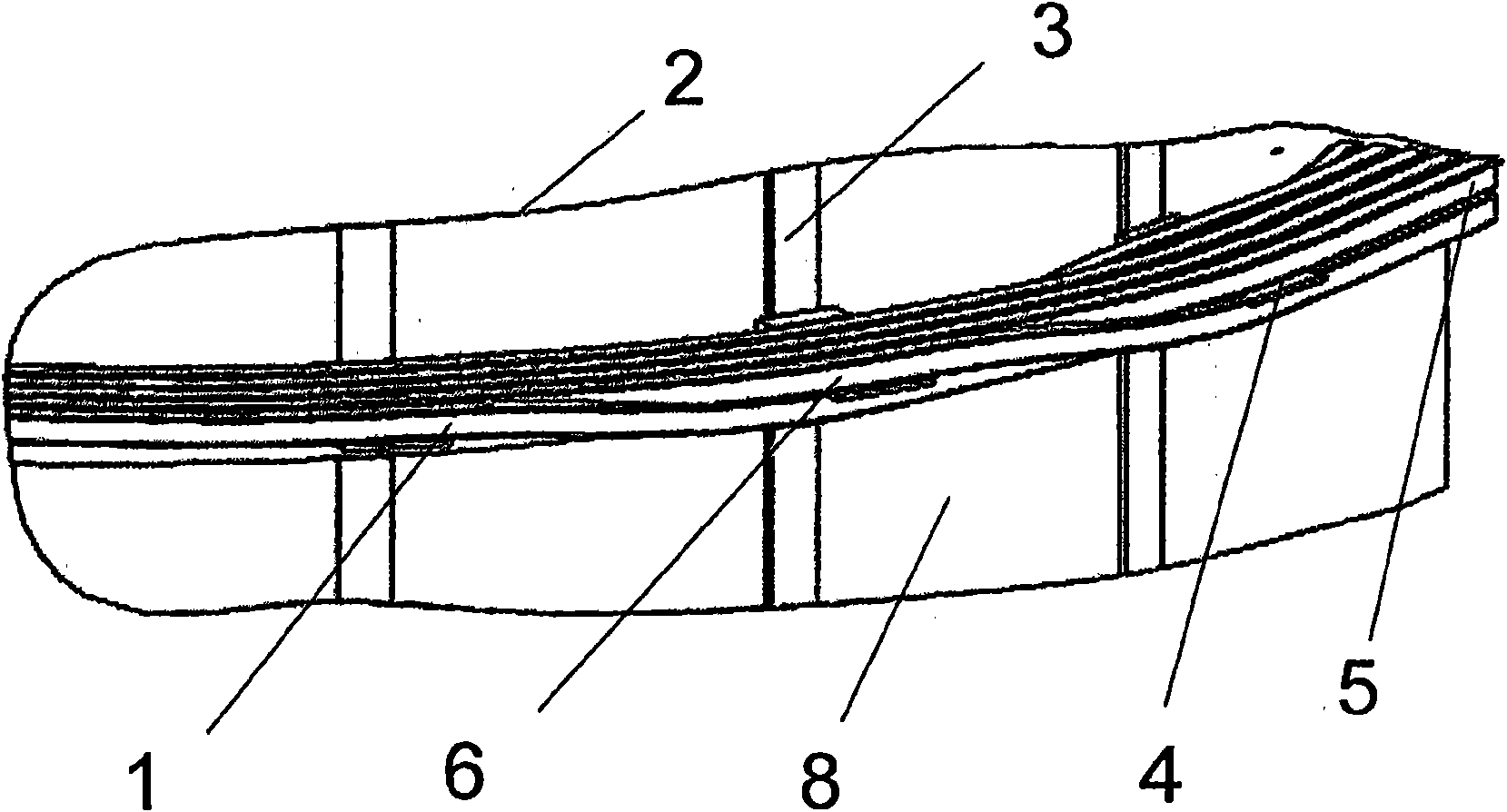

[0020] figure 1 A partial schematic diagram of a disc winding of a power transformer according to the invention is shown. The disk winding consists of a conductor (1) wound on an insulated coil post (2). The rods (3) ensure the axial flow of the coolant, but are also arranged to align with the insulating spacers (4). A disk (5) usually consists of several radial turns of a conductor (1) and is axially separated from the previous and subsequent disks by insulating spacers (4). The space between two spacers (4) is called spacer pitch (8). According to the invention, in one segment, the conductor (1) is transferred from one disc to the other by bending the conductor (1) into a twin cross-over (6).

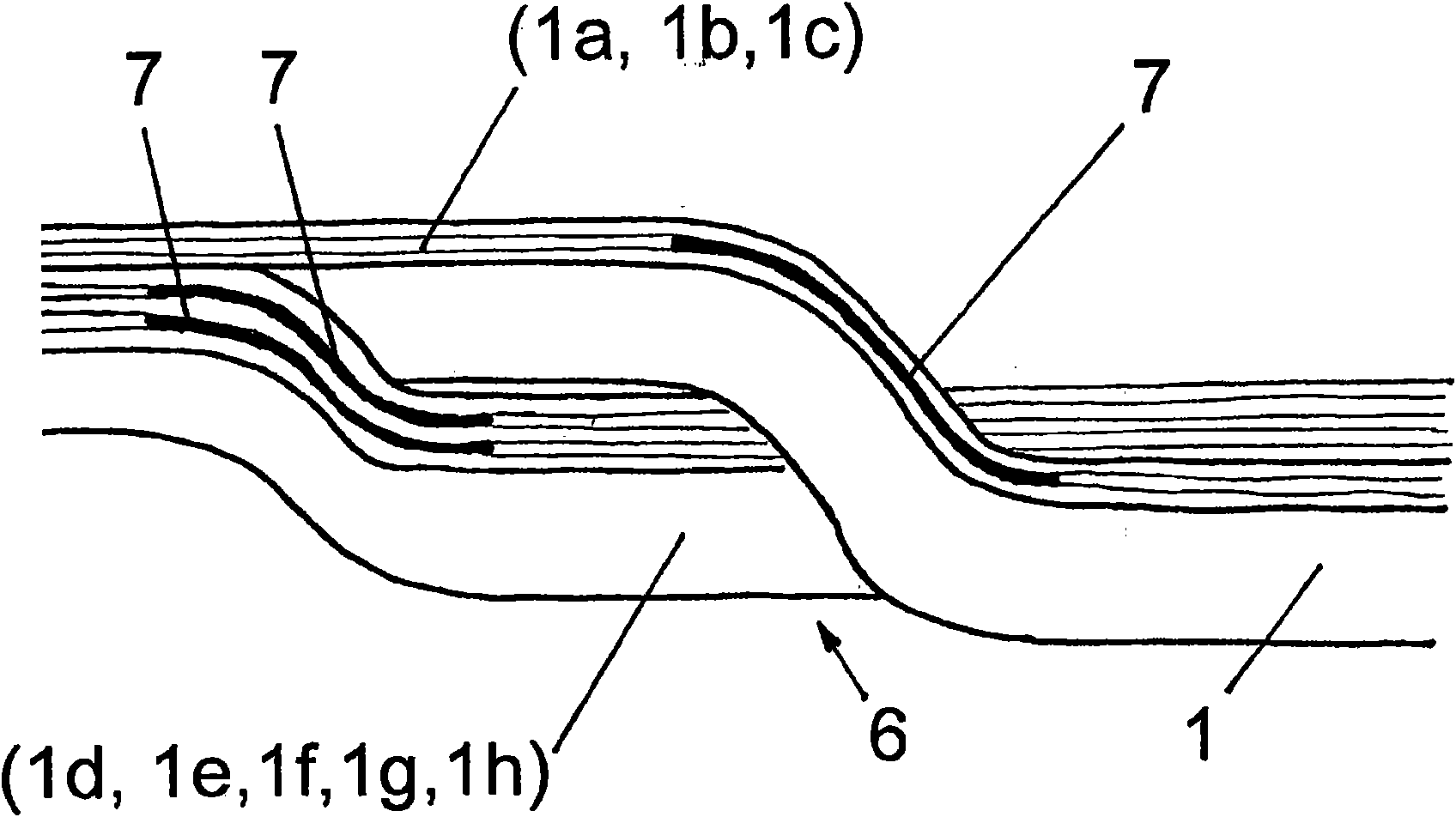

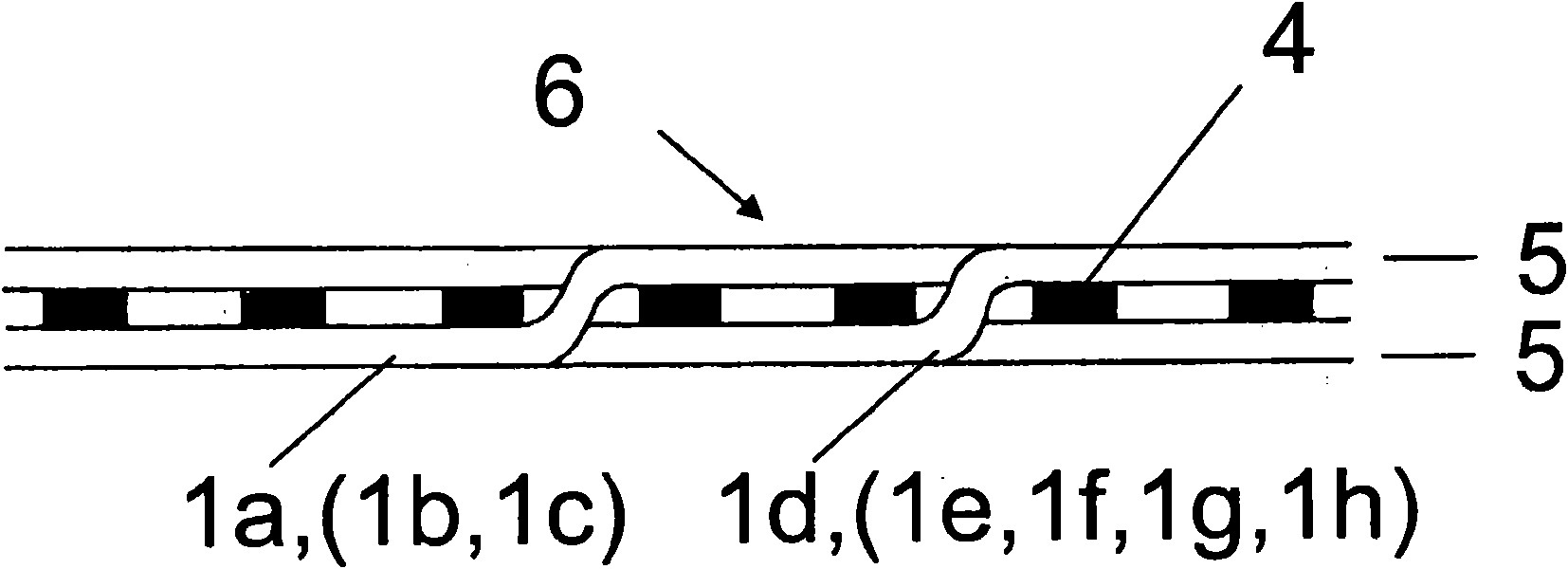

[0021] figure 2 A detailed schematic of the double crossover (6) is shown. A conductor (1) consists of eight substantially parallel stranded conductors (1a, . . . , 1h). In a double crossover (6), a first set of three adjacent stranded conductors (1a, 1b, 1c) is in a first spa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com