Vibration and noise complex experiment equipment

A technology of noise test and composite test, applied in noise composite test equipment and vibration field, can solve problems such as single vibration or noise test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

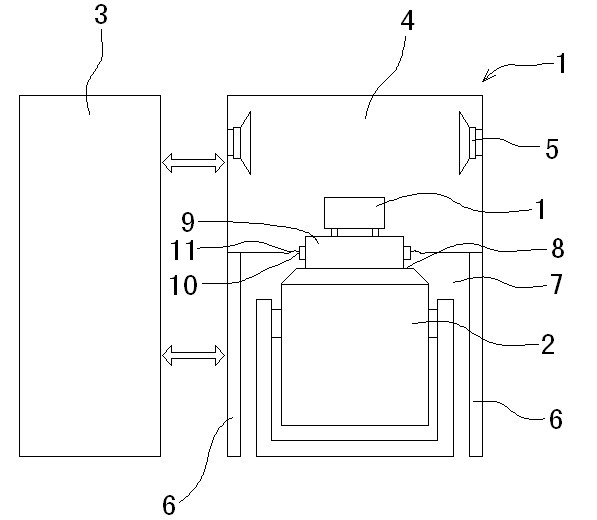

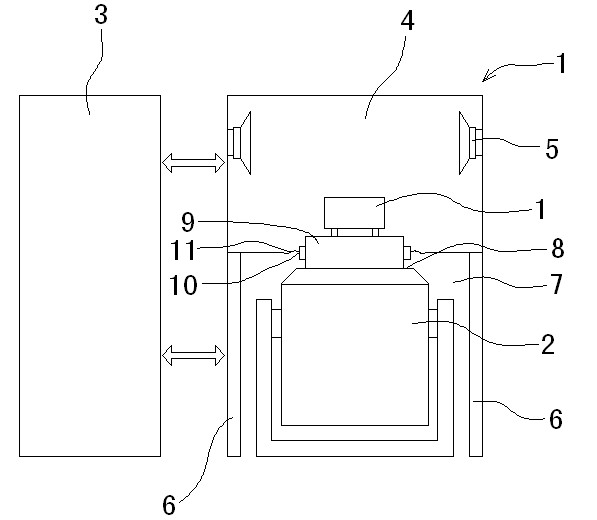

[0018] See attached figure 1 As shown, a vibration and noise composite test equipment is mainly composed of three parts: noise test box 1, vibration table 2 and control box 3.

[0019] Wherein, the noise test chamber 1 is an airtight box with an acoustic cavity 4 inside, and at least one sound generating device 5 is arranged in the acoustic cavity 4; After being driven by the spectral sound signal, the required sound field is excited in the sound cavity 4 (multiple sets of sound generating devices 5 can be set according to the sound power required for the test).

[0020] The noise test box 1 is supported by a bracket 6 opposite to the ground, and an accommodating space 7 is formed under the noise test box 1 , and the vibrating table 2 is set in the accommodating space 7 .

[0021] Such as figure 1 As shown, an extension head 9 is fixedly arranged on the moving coil table top 8 of the vibrating table 2, and the upper end of the extension head 9 fixes the test piece 12 by a sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com