Scappling handle cutter

A cutting tool and cutting tool technology, which is applied in the direction of manufacturing tools, clamping, supporting, etc., can solve the problems of the influence of the strength of the tool handle, the difficulty of ensuring the coaxiality of the tool, and disadvantages, and achieve the effect of preventing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

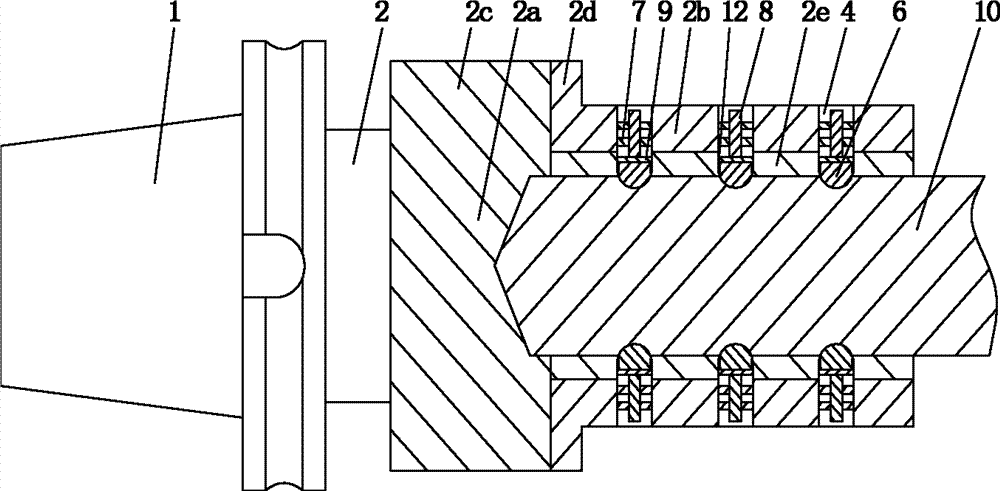

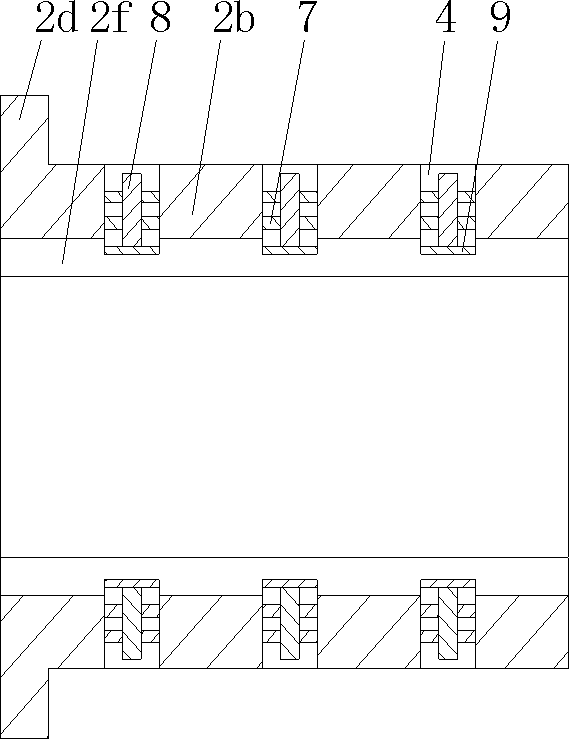

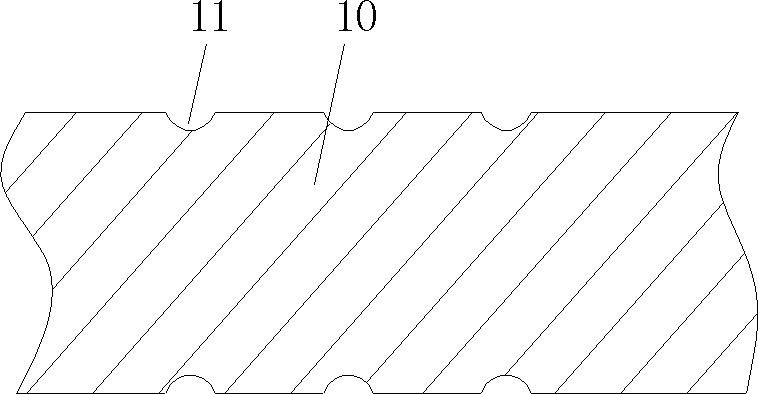

[0020] refer to figure 1 , the flat handle tool of the present invention includes a clamping handle 1 and a tool bar 2, the tool holding handle is a Morse cone, and an annular boss is provided on the clamping handle, and an annular groove for clamping is provided on the annular boss . The tool bar 2 is provided with a tool assembly hole 3, and the center of the tool assembly hole 3 is on the same line as the axis of the clamping handle 1. A cutting tool 10 is fixed in the tool mounting hole. Radial through-holes are arranged symmetrically on the circumferential surface of the cutter bar 2 , and the through-holes communicate with the cutter assembly hole 3 . Through hole is made of straight hole 4 and spherical hole, is provided with steel ball 6 in spherical hole, and steel ball is hemispherical steel ball. The cutter bar 2 includes a cutter assembly rod 2a and a sleeve 2b fixed circumferentially with the cutter assembly rod, the spherical hole is located on the cutter asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com