Roll reduction container crane and roll reduction mechanism thereof

A technology of containers and cranes, applied in the field of cranes, can solve problems such as poor anti-sway effects, and achieve good anti-sway effects of spreaders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0016] The embodiment of container crane of the present invention is as follows:

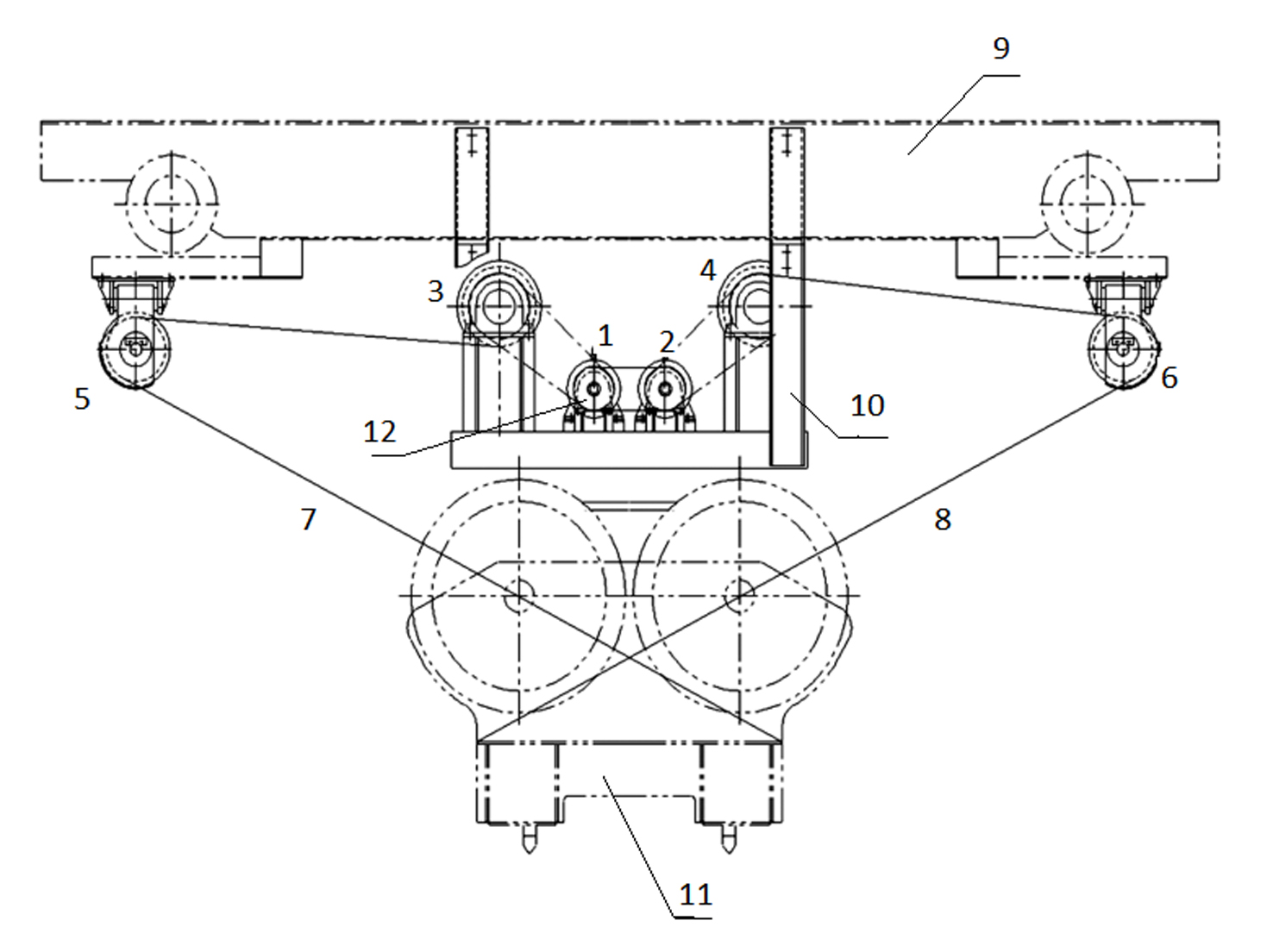

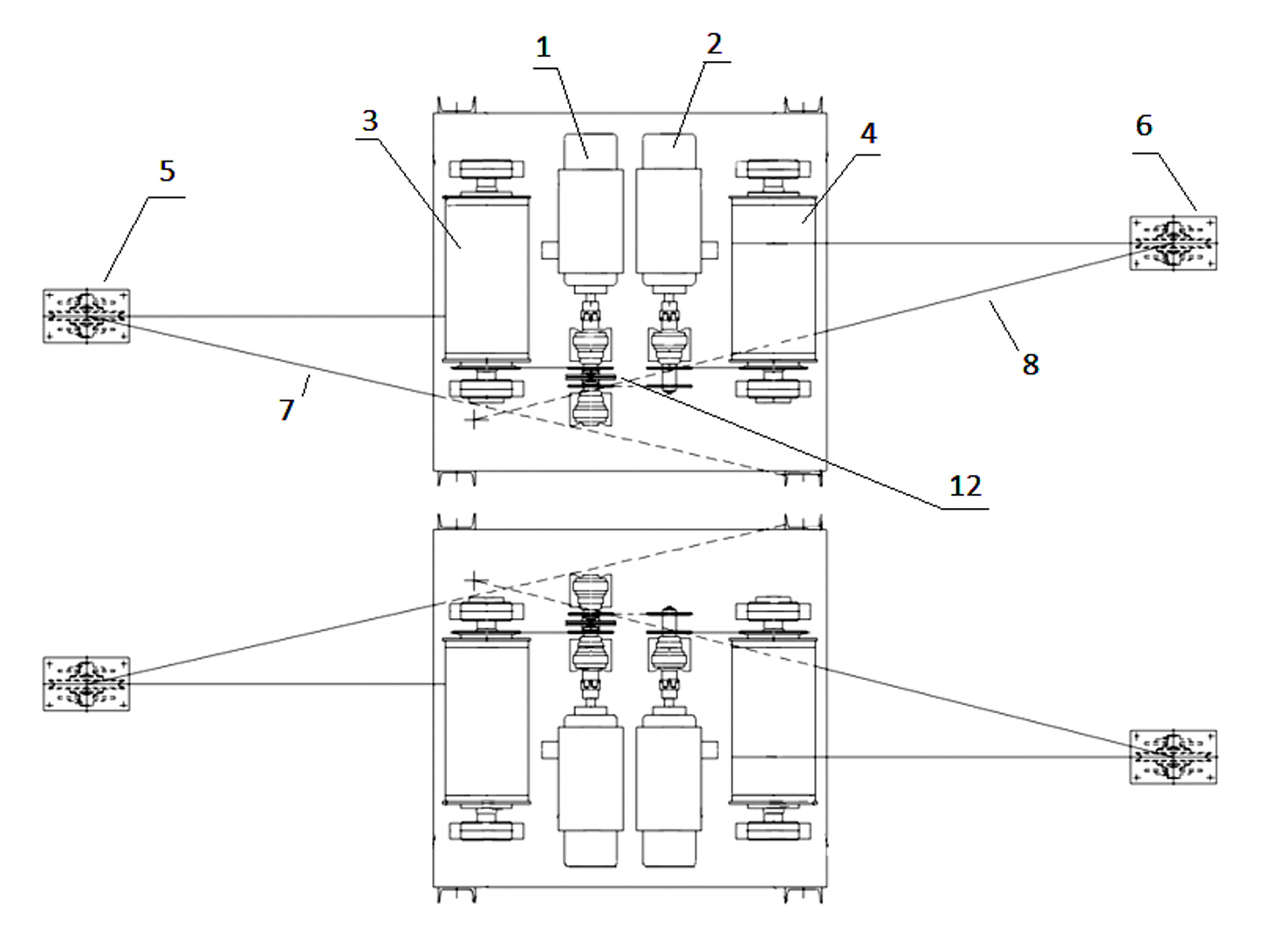

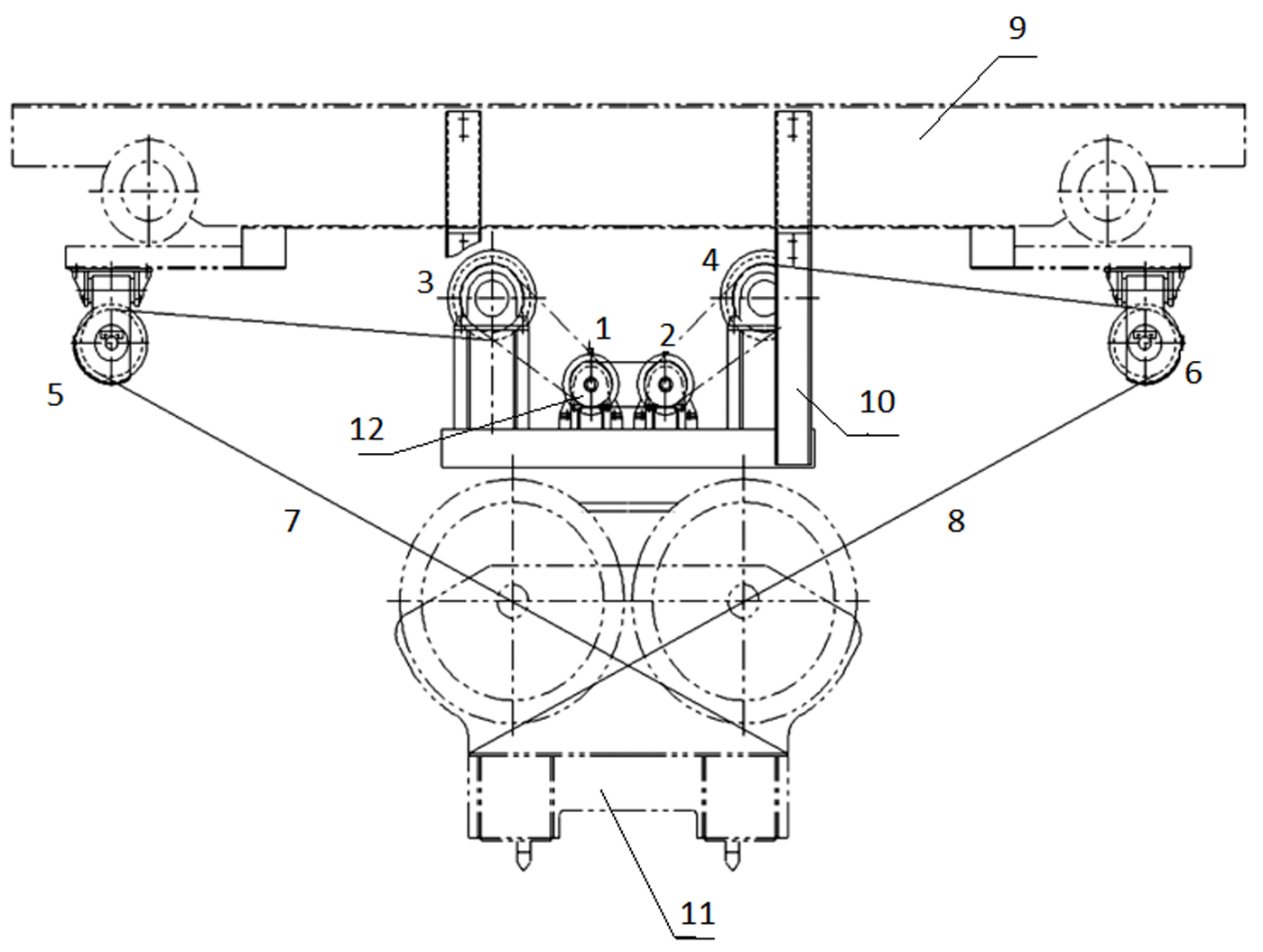

[0017] Such as figure 1 , figure 2 The anti-rolling container crane shown includes a trolley 9 and a spreader 11 below the trolley. The crane 9 is provided with two sets of anti-sway mechanisms corresponding to two ends of the spreader 11 respectively. The anti-rolling mechanism includes a pair of fiber-drawing driving devices parallel to the running direction of the trolley. The rotating shafts of the two devices are perpendicular to the traveling direction of the trolley. The first fiber-drawing driving device includes: the first reel driving motor 1, which drives the first reel through the gear chain structure. Drum 3, the pulley 5 on the outside of the first reel 3, the first anti-sway stay rope 7 is wound on the first reel 3, the first anti-sway stay rope 7 passes throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com