Multifunction sorting machine

A kind of material selection machine, multi-functional technology, applied in the direction of solid separation, filter screen, grille, etc., can solve the problems of material selection machine easy to fall, material selection machine electrification, electric shock workers, etc., to improve material selection accuracy, material selection Effects of quality improvement and noise reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

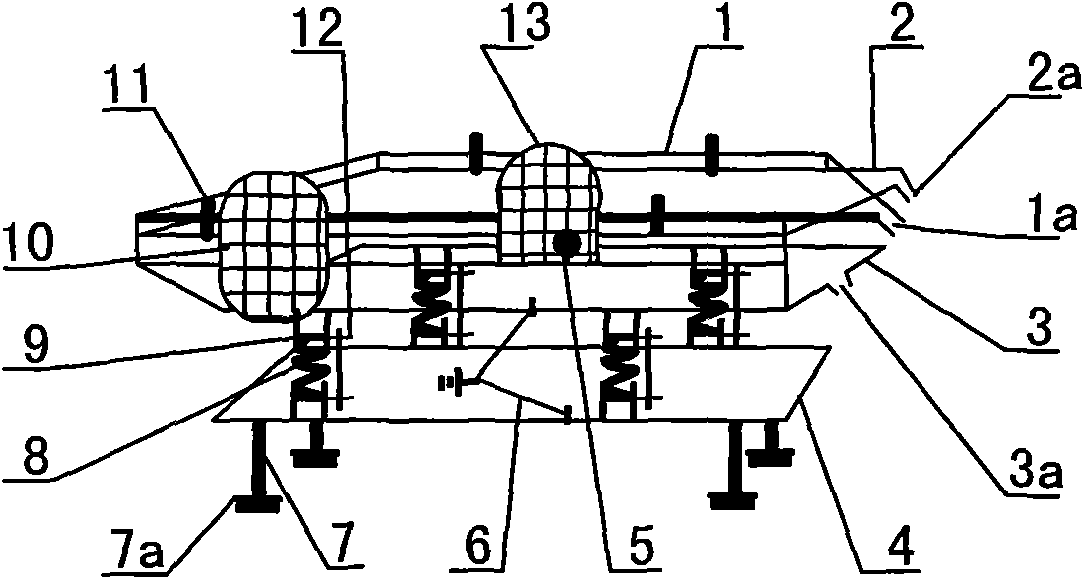

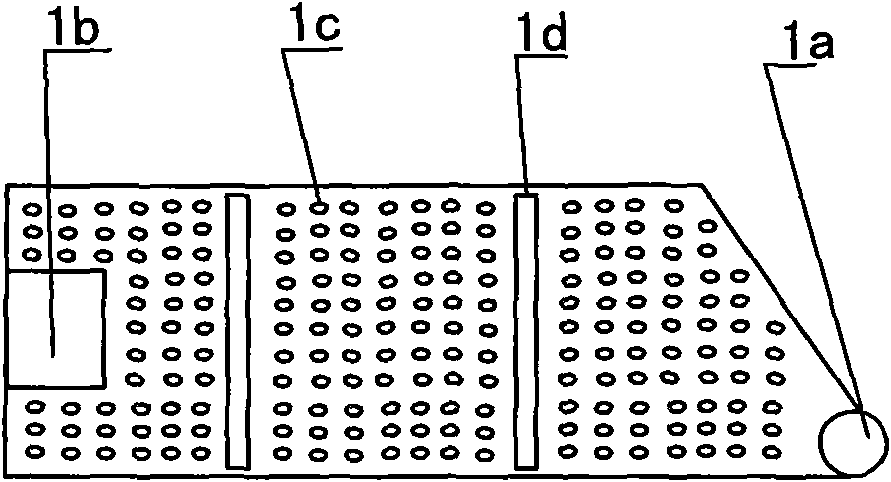

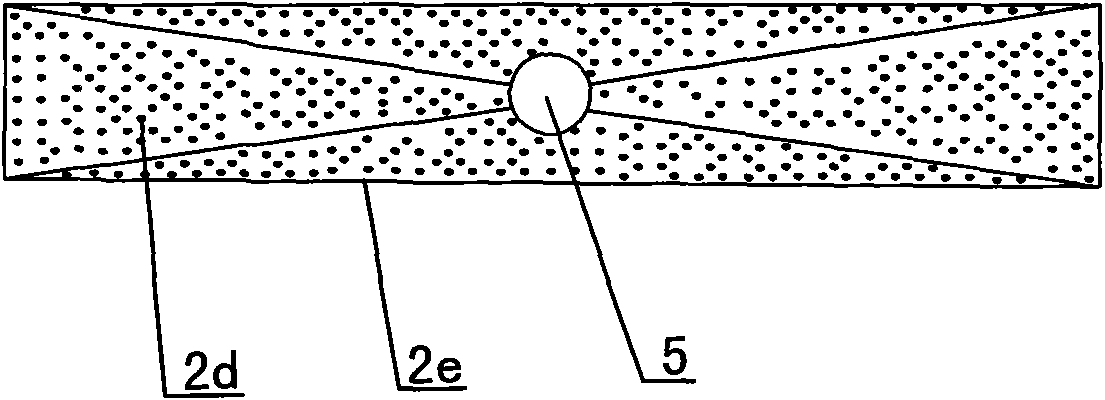

[0033] Such as figure 2 As shown, a large material screen 1 is made, including a large material outlet 1a, a material direction changing device 1b, a large material screen hole 1c and a large material screen reinforcing rib 1d, and the material direction changing device 1b is a vertical solid plate , The diameter of the large material screen hole 1c is 3mm, and the angle iron is welded under the large material screen reinforcement rib 1d. Such as image 3 In the shown standard material screen 2, the standard material screen hole 2b is smaller than the standard material diameter of 1mm, the angle iron is welded under the standard material screen reinforcing rib 2c, and the standard material screen side plate 2e is made with a dust suction hole 2d with a diameter of 1mm , there is a vacuum cleaner interface 5 in the middle of the standard material screen side plate 2e, such as figure 1 The shown vacuum cleaner 13 is connected to the vacuum cleaner interface 5, and the vacuum ...

Embodiment 2

[0036] Make large material screen 1, comprise large material outlet 1a, material direction changing device 1b, large material screen hole 1c and large material screen reinforcing rib 1d, material direction changing device 1b is an upright solid plate, large The diameter of the material screen hole 1c is 4mm, and the angle iron is welded below the reinforcement bar 1d of the large material screen. The standard material screen hole 2b in the standard material screen 2 is 2mm smaller than the standard material diameter, and the angle iron is welded below the standard material screen reinforcing rib 2c. A dust suction hole 2d with a diameter of 2mm is made on the standard material screen side plate 2e, and a vacuum cleaner interface 5 is provided in the middle of the standard material screen side plate 2e, such as Figure 4 The shown vacuum cleaner is integrated with the chassis bracket 4 of the material selection machine: the vacuum cleaner 13 is installed on the chassis bracket ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap