Head-sealed pressed cable

A technology of rigging and rope heads, which is applied in the field of rigging, can solve the problems of rope head piercing hands, reduction of consolidation force, consolidation deformation of consolidation ends, etc., so as to protect one's own safety, reduce mutual collision damage, avoid The effect of safety hazards

Inactive Publication Date: 2011-04-27

江阴艺林索具有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

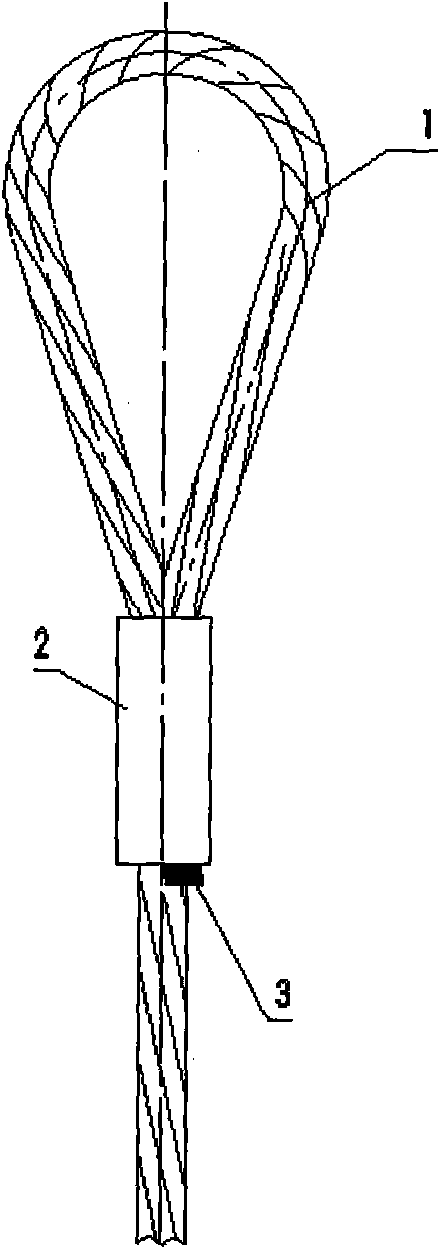

[0003] (1) There are acute angles at the upper and lower ends of the consolidation end of the conventional pressing rigging, such as figure 1 As shown, when hoisting, it often rubs against some hard objects, causing the consolidation deformation of the consolidation end, resulting in a decrease in the consolidation force, the actual hoisting of the rigging cannot reach its nominal capacity, and the safety and reliability of hoisting cannot be guaranteed.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

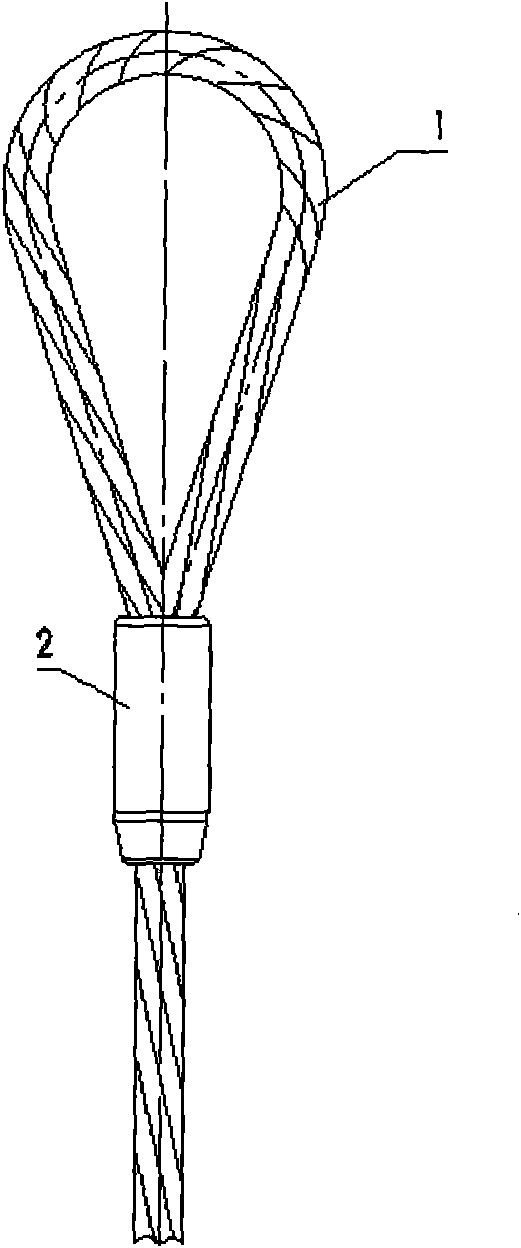

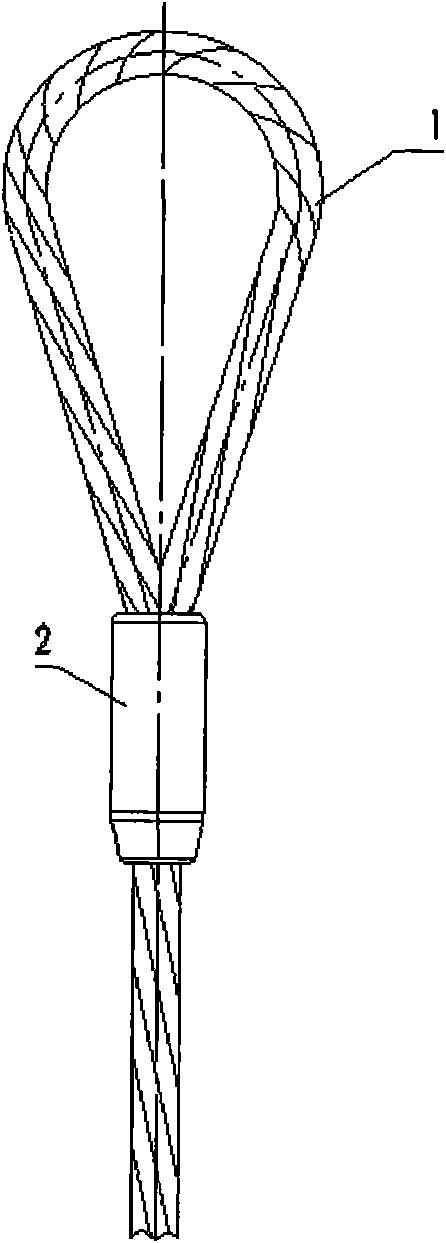

[0013] see figure 2 , the head-type pressing rigging involved in the present invention includes a rigging 1, a rigging consolidation end 2 and a consolidation end rope head 3, and is characterized in that the upper and lower ends of the rigging consolidation end 1 adopt circular arc transitions , the rope head 3 at the fixing end is sealed and pressed in the fixing end 2 of the sling so as not to be exposed.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a head-sealed pressed cable, which is used for hoisting articles in various fields of ships, oil fields, construction, elevators, ports, docks, projects, cableways, coal mines and the like. The head-sealed pressed cable comprises a cable (1), a cable fixed end (2) and a fixed end cable head (3). Both the upper end and the lower end of the cable fixed end (2) are in uniform arc transition. The fixed end cable head (3) is sealed and pressed in the cable fixed end (2) and is unexposed. In the hoisting of the head-sealed pressed cable, the cable fixed end can reduce frictional damages with other hard objects; and when the head-sealed pressed cable is carried and used, the cable fixed end does not prick hands.

Description

(1) Technical field [0001] The invention relates to a rigging. It is widely used in the hoisting of objects in various fields such as ships, oil fields, buildings, elevators, ports, docks, engineering, cableways and coal mines. It belongs to the technical field of hoisting tools. (2) Background technology [0002] The current pressing rigging is generally processed and manufactured according to the German standard DIN3093 and the national standard GB6946. Although its mechanical and other properties can meet the standard requirements, there are the following defects in the actual hoisting of the rigging: [0003] (1) There are acute angles at the upper and lower ends of the consolidation end of the conventional pressing rigging, such as figure 1 As shown, when hoisting, it often rubs against some hard objects, which causes the consolidation deformation of the consolidation end and reduces the consolidation force. The actual hoisting of the rigging cannot reach its nominal...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B66C1/12

Inventor 张晓张玉成朱志贵

Owner 江阴艺林索具有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com