A Blasting Method for Segmented Differential Slump in Medium and Deep Holes

A differential, deep hole technology, applied in the field of engineering rock and soil blasting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

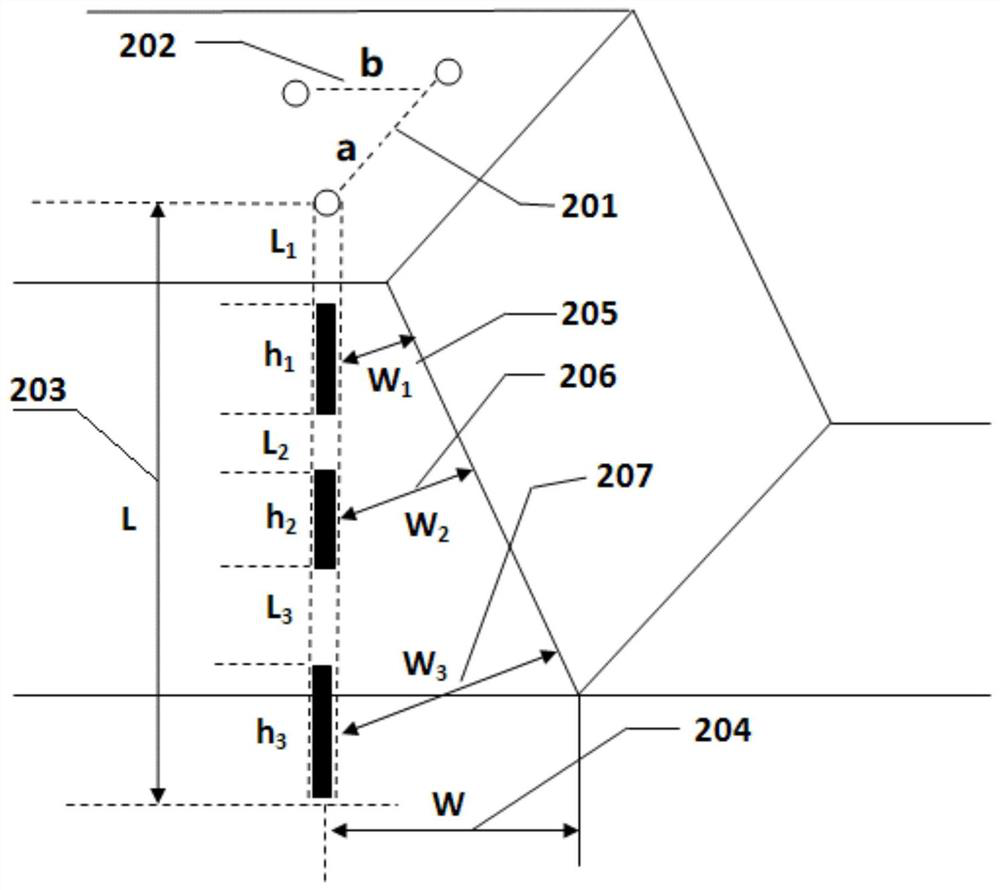

[0069] In order to enable those skilled in the technical field to which the application belongs to understand the application more clearly, the technical solutions of the application will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

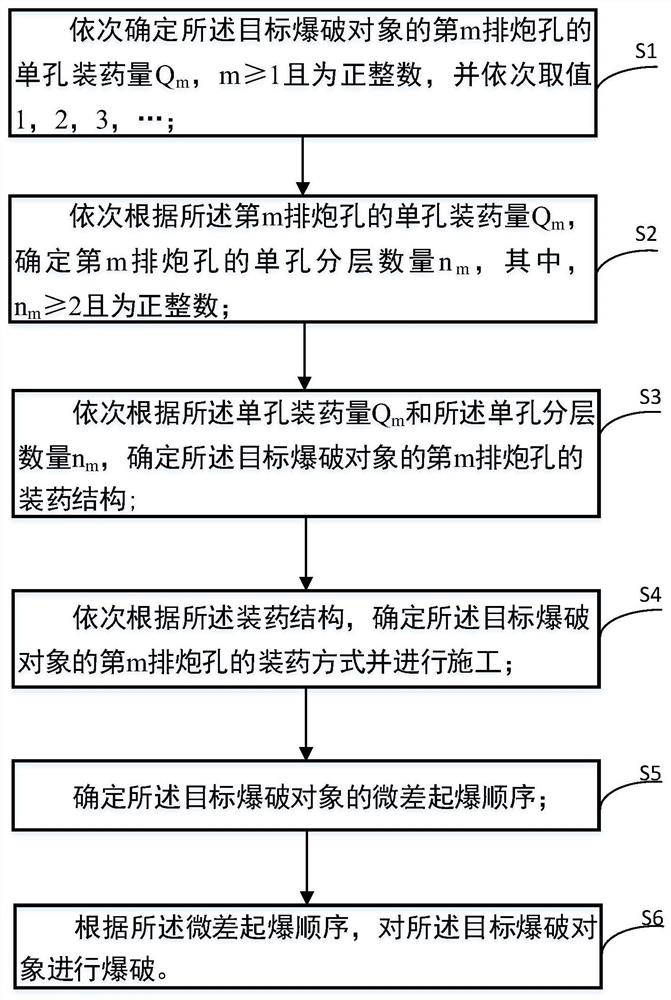

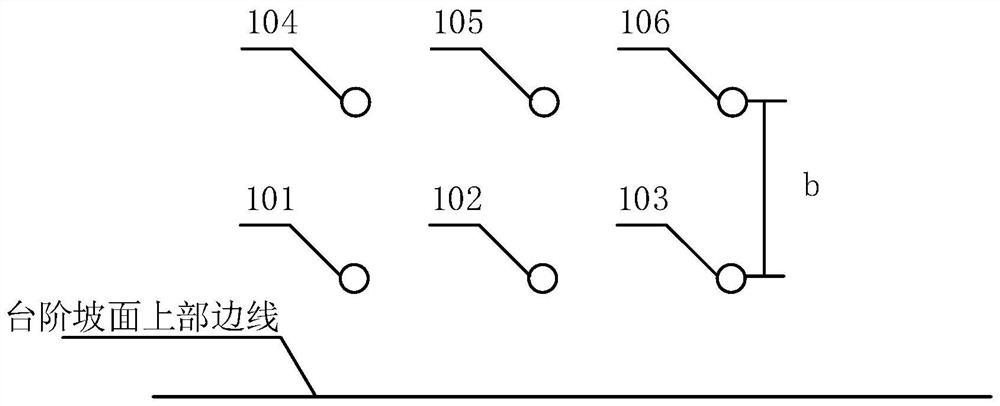

[0070] In order to control the blasting of slag removal steps in medium and deep holes, reduce the front rush of slag removal blasting, improve the blasting quality, and control the harmful effects of blasting, the present invention provides a blasting method for medium and deep holes with sub-level differential collapse. The number of rows of blast holes in the blasting object is ≥ 1, and the number of blast holes in each row is ≥ 2. figure 1 , the steps of the blasting method include:

[0071] S1: sequentially determine the single-hole charge Q of the m-th row of blasting holes of the target blasting object m , m≥1 and is a positive integer, and takes values 1, 2, 3, ... in turn;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com