Acoustic releaser actuating mechanism capable of cutting cable

A releaser and cable technology, applied in the field of acoustic releaser actuators, can solve the problems of non-repetitive use, high use cost, small underwater load, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

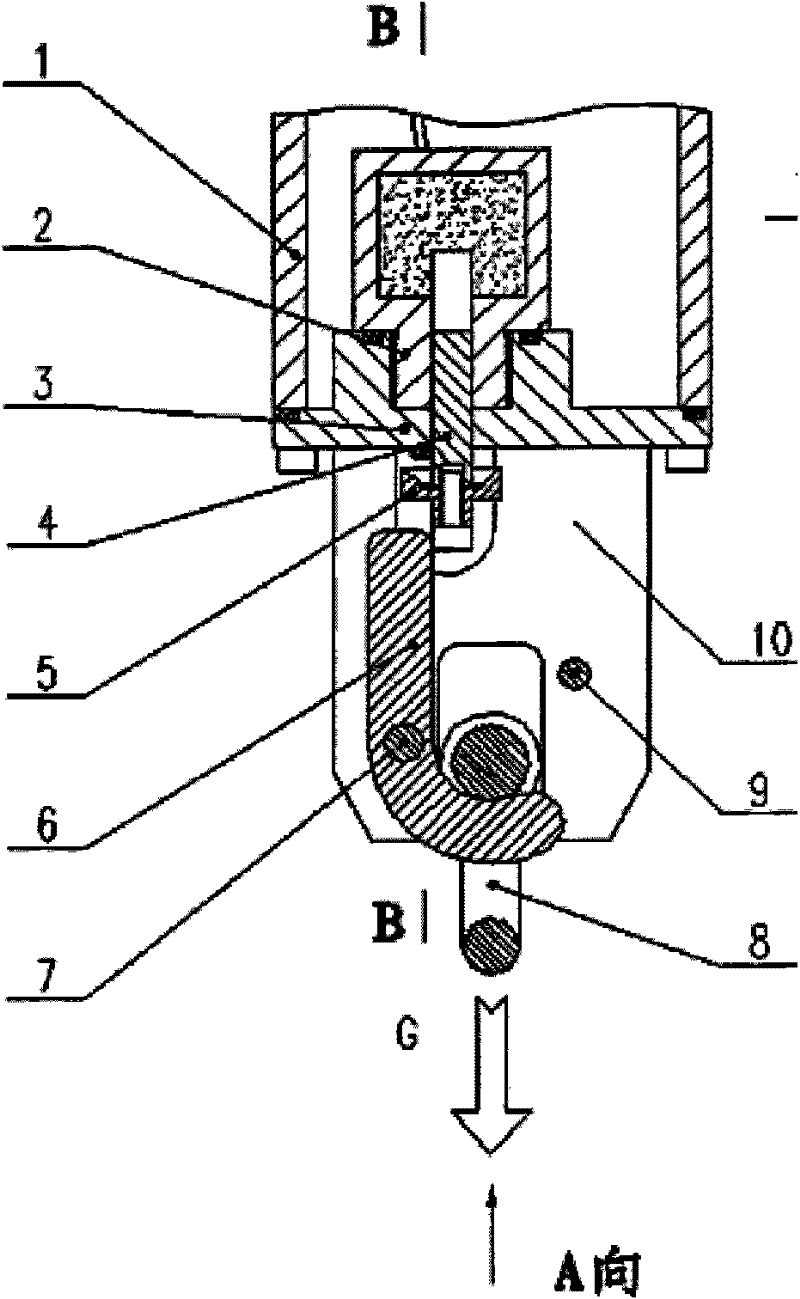

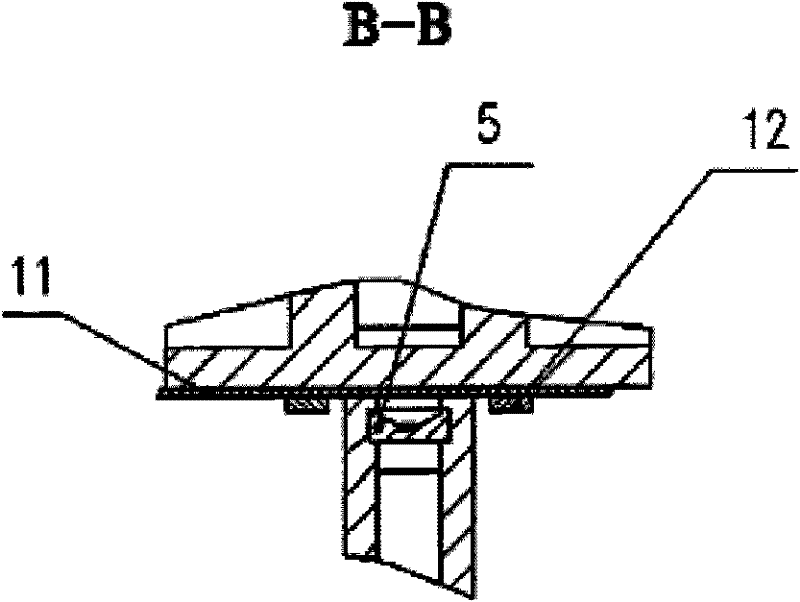

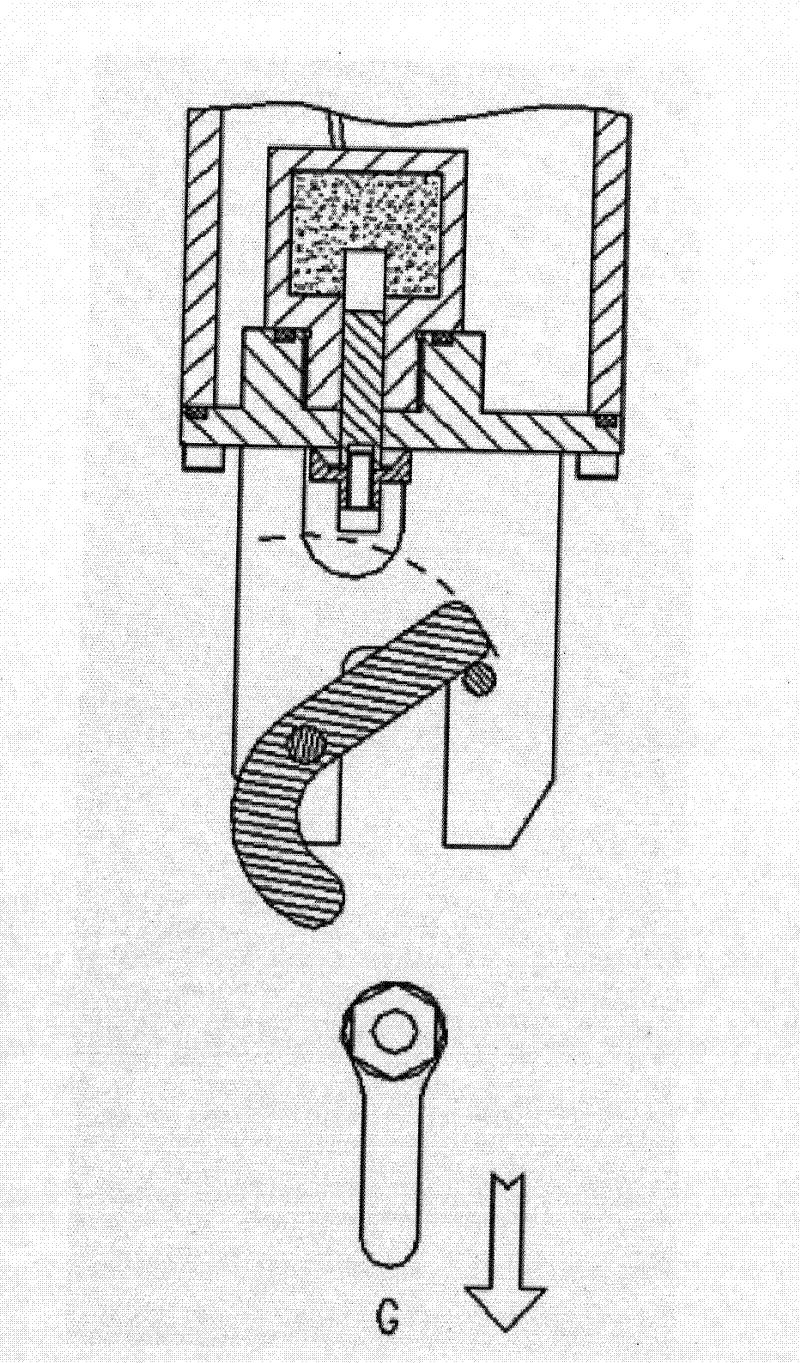

[0017] as attached figure 1 , 2 , 3, the actuator of the acoustic release is composed of a sealed housing 1, a pneumatic pin puller 2, a release base 3, a pin puller pin 4, a cutter 5, a release hook 6, a release hook shaft 7, a limiter It is composed of bit shaft 9, releaser caliper 10, cable pressing plate 12 and the like.

[0018] First pass the cable 11 to be cut through the cable hole of the pin shaft 4 of the pin puller, then press the two ends with the cable pressure plate 12 respectively, set the cutting knife 5 on the pin shaft 4 of the pneumatic pin puller 2, and then use the nut Press firmly.

[0019] The release hook 6 is installed and fixed in the interlayer of the release caliper 10 through the release hook rotating shaft 7. When the upper end of the release hook leans against the pin 4 of the pneumatic pin puller 2, the lower end and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com