Decompression drying apparatus

A decompression drying device and drying technology, which are used in optics, instruments, optomechanical equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Hereinafter, preferred embodiments of the present invention will be described with reference to the drawings.

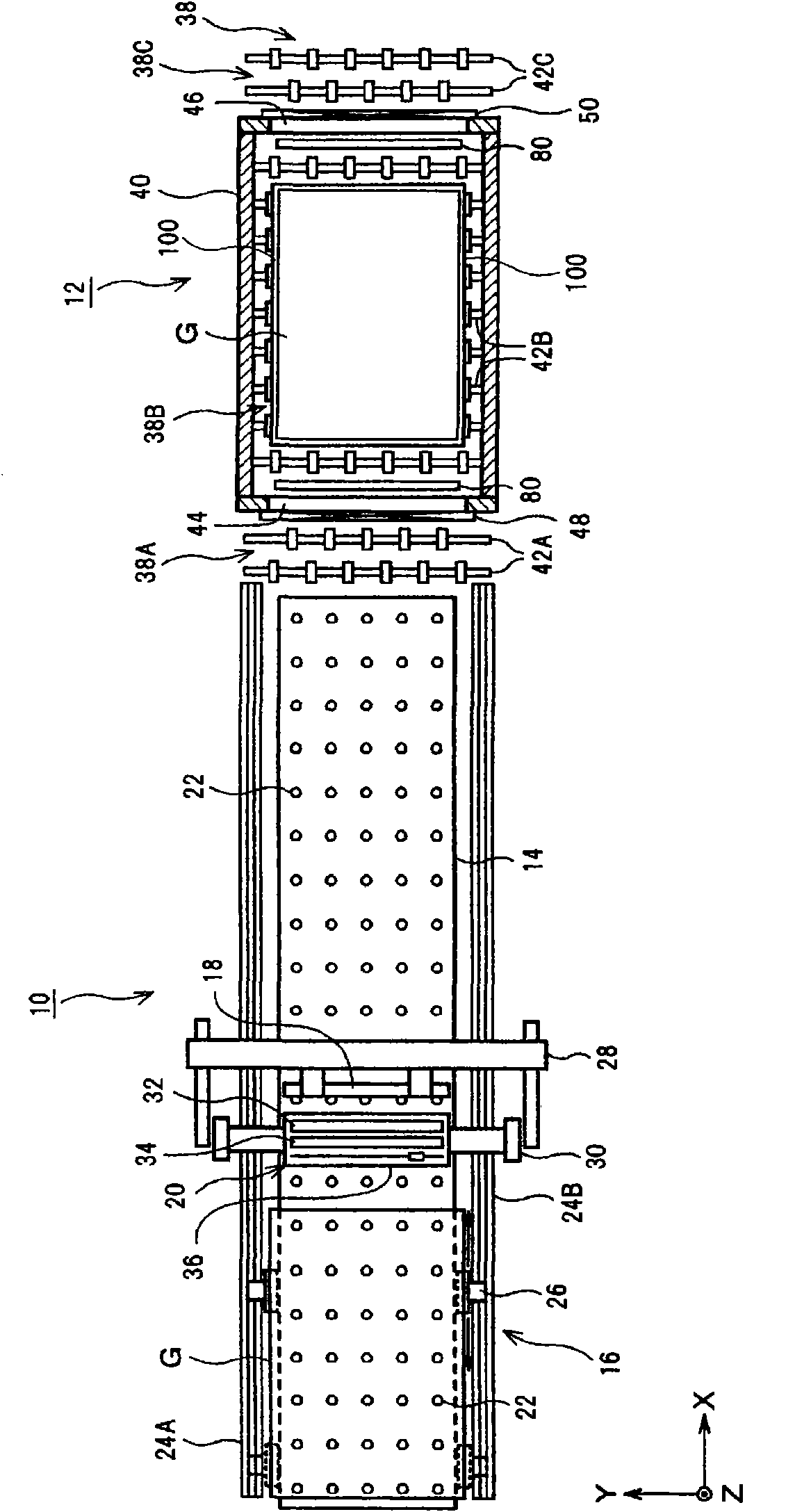

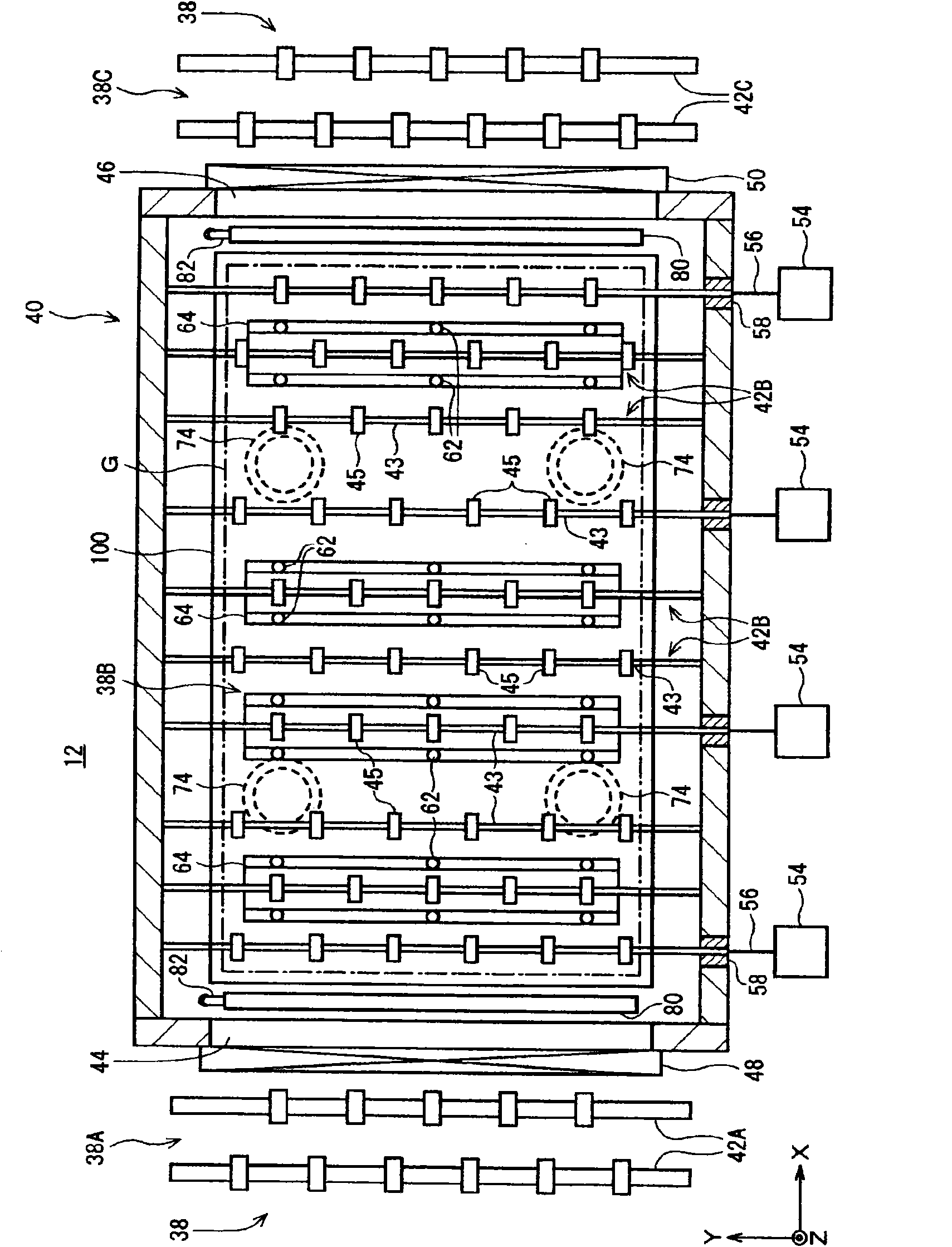

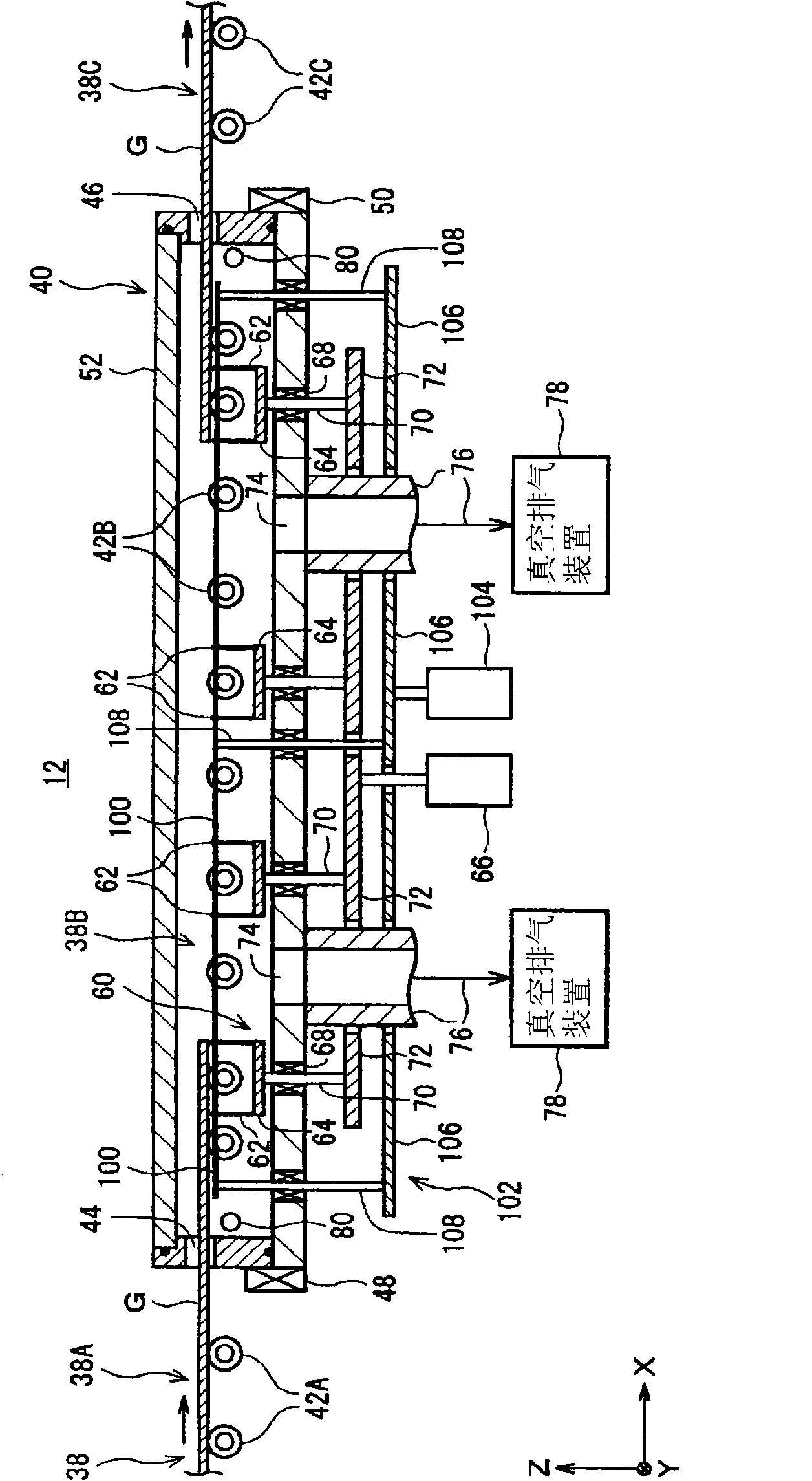

[0055] figure 1 A configuration example of a resist coating apparatus for FPD production to which the reduced-pressure drying apparatus of the present invention is applied is shown.

[0056]In this resist coating apparatus, an advective resist coating unit 10 and a reduced-pressure drying unit 12 are arranged in parallel in the same substrate transfer direction (X direction). First, the configuration and function of the resist coating unit 10 will be described.

[0057] The resist coating unit 10 has: a floating stage 14 that floats a substrate to be processed, such as a glass substrate G, by air pressure and supports it horizontally; The substrate conveying mechanism 16 that conveys the stage longitudinal direction (X direction); the resist nozzle 18 that supplies the resist liquid to the upper surface of the substrate G conveyed on the floating stage 14; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com