One-step molding method of split foot with grounding hole

A grounding hole and split technology, which is applied in the field of one-step forming of air-conditioning compressor feet, can solve the problems of unguaranteed quality stability of workpieces and low efficiency of punching grounding holes, achieving consistent efficiency, improving production efficiency, and overcoming rhythm. The effect of restriction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

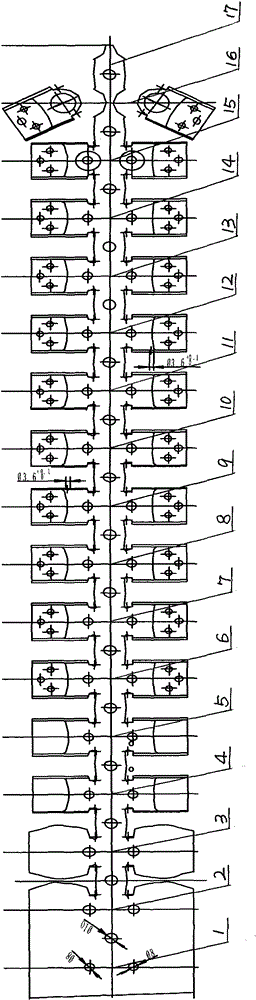

[0024] see figure 1 , the steps of one-time forming method for the foot are

[0025] 1. Set the step distance not less than the width of the expanded drawing of the foot, which is D (60) mm. After the plate to be processed with a thickness of T (2.5) mm is leveled by special equipment, punch two installation holes and pre-hole A. The hole diameter is not less than 1.5 times the material thickness (Φ8) (unit is mm, the same below) and a step positioning hole B, the hole diameter is not less than 1.5 times the material thickness (Ф10), as the subsequent positioning hole, the step positioning hole is located In the direction of the plate axis, the pre-holes of the mounting holes are symmetrical about this axis, and the three holes are distributed in an isosceles triangle. The distance between the two mounting holes is the sum of the arc radii of the mounting holes of the two feet and the sum of not less than 1 times the thickness of the plate. See reference number 1;

[0026] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com