Oiler for textile machines

A textile machine and oil cup technology, applied in textiles, papermaking, knitting, etc., can solve problems such as harmfulness, and achieve the effects of good cross-sectional area, less compressed air volume, and high input pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

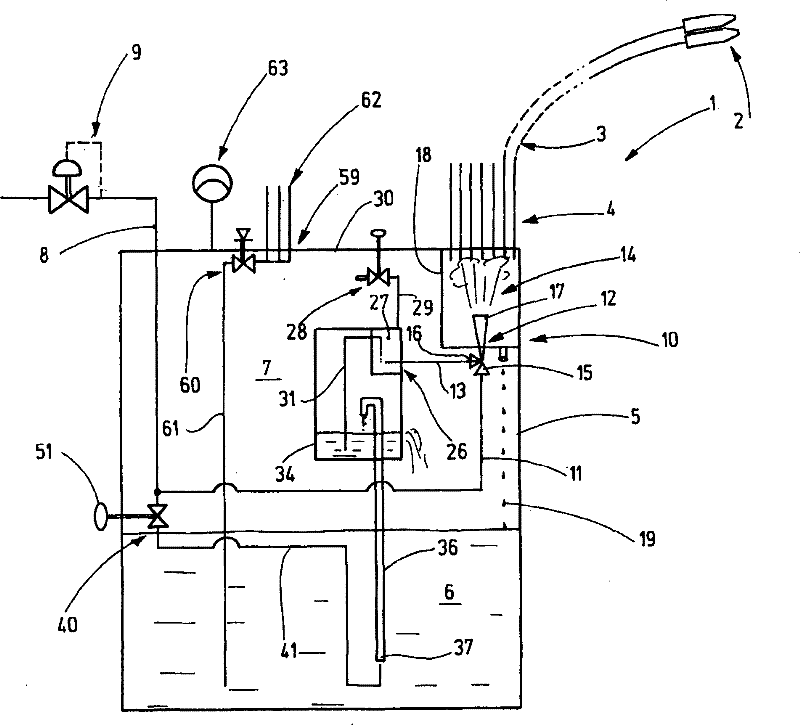

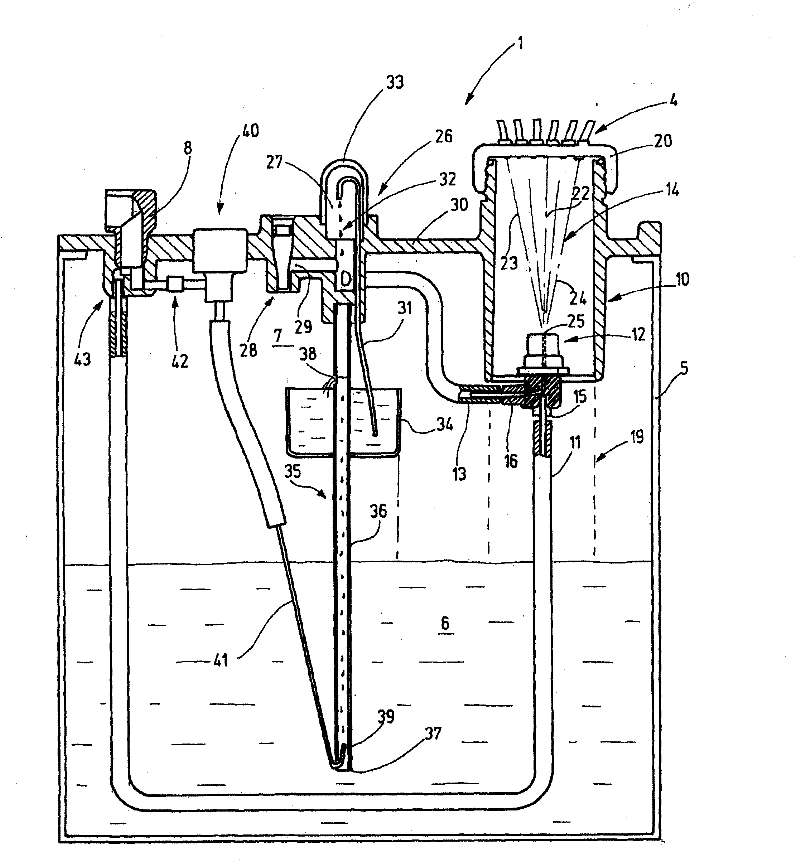

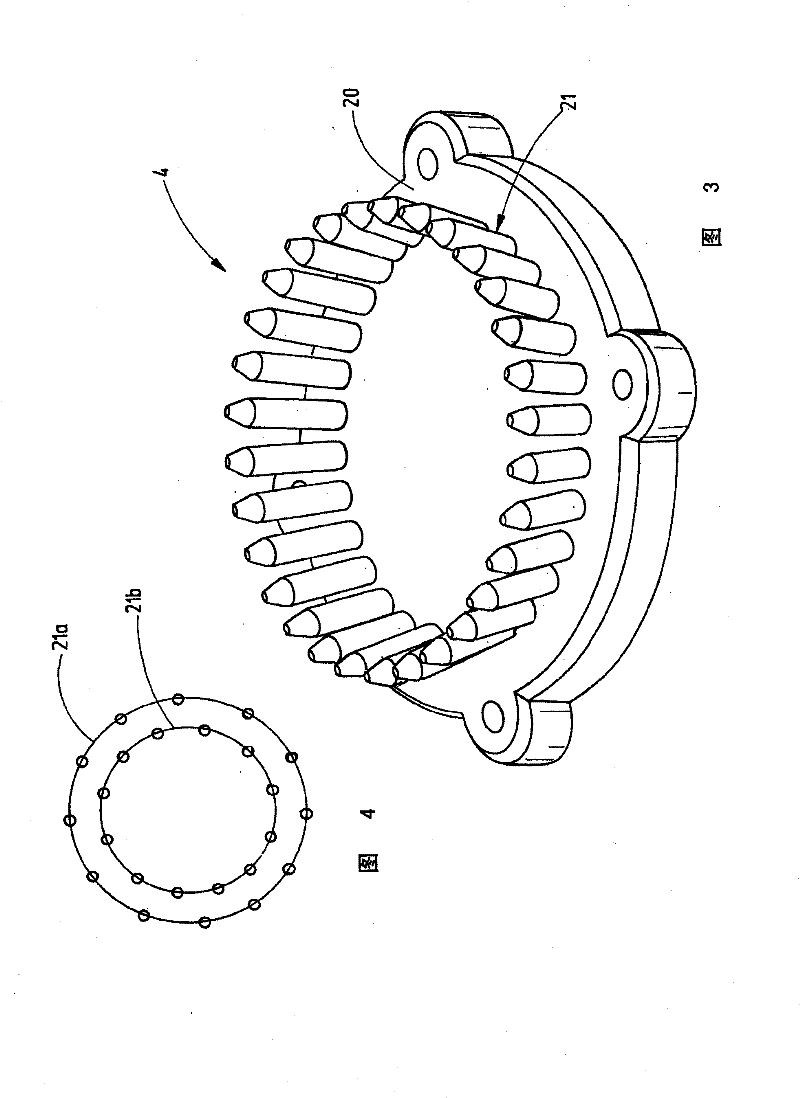

[0028] figure 1 Shown is a textile machine oil cup 1 for supplying multiple lubrication points of two not further shown textile machines, such as circular knitting machines. Multiple lubrication positions 2 in figure 1 is shown by a representatively indicated nozzle, to which the line 3 leads. These lines 3 connect the nozzles with corresponding ports 4 which are provided, for example, on the top surface of the oil cup 1 for the textile machine. A suitable nozzle is obtained, for example, from WO2007 / 064588A2.

[0029] The oil cup 1 for a textile machine includes a cup groove 5 surrounding an inner cavity. Reserve oil 6 is housed in the inner cavity, and an air cushion 7 is arranged above the reserve oil. The air cushion is enclosed in the externally closed cup 5 and has a slightly higher pressure relative to the environment, for example 0.2, 0.3, 0.4 bar or a similar pressure. Air reaches these lubrication points 2 from an air cushion 7 via ports 4 and lines 3 . The air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com