Fastening device and method for fastening an element in a key-hole shaped cut-out of a wall

A technology of fixing devices and keyholes, which is applied in the direction of connecting components, thin plate connections, circuits, etc., can solve problems such as the inability to ensure the reliable execution of sensor functions, and achieve the effect of simple anti-twist protection function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

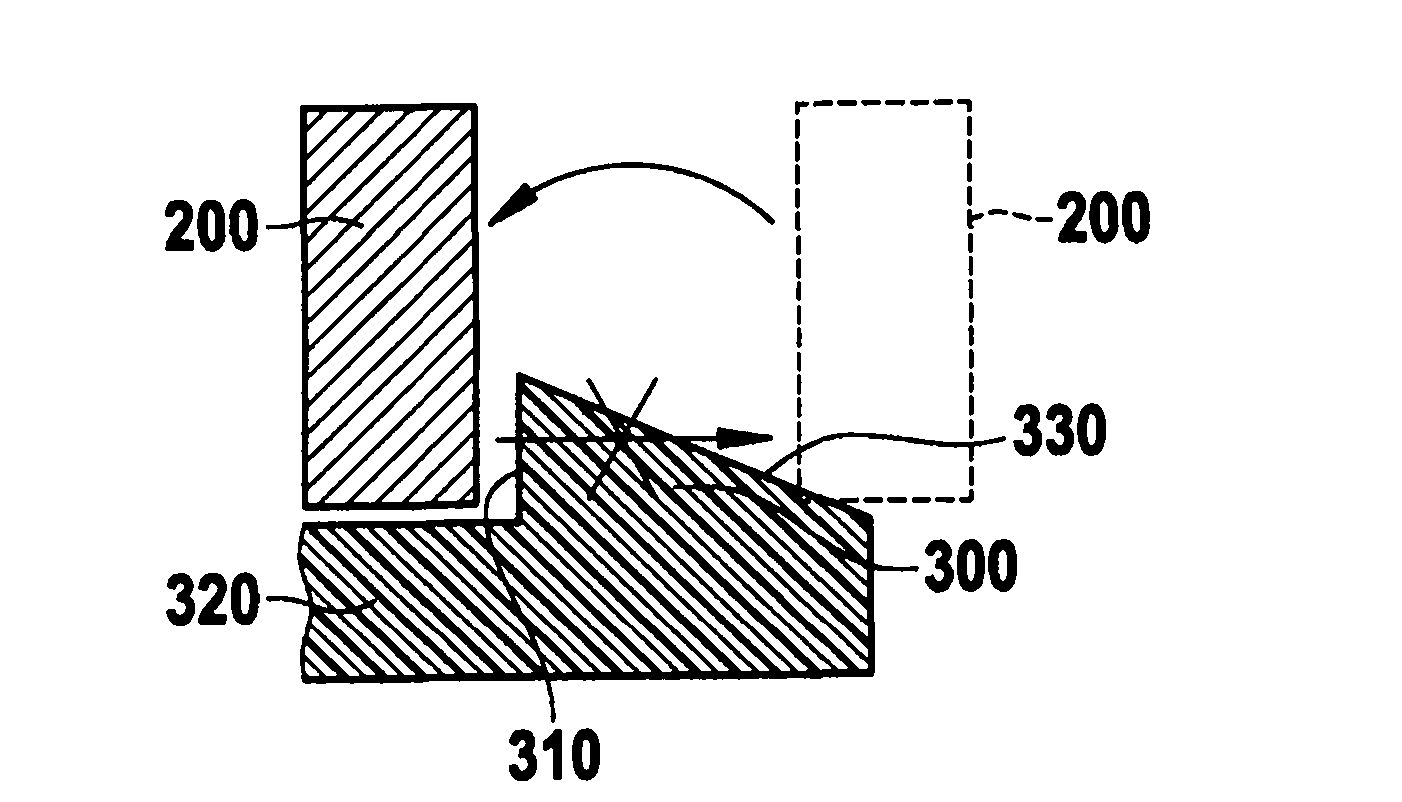

[0031] It is an object of the invention, in particular, to ensure an extended protection against twisting when mounting components using the keyhole principle. Here, it is to be avoided that the part falls out partially after the insertion process of the mounting bolt into the keyhole. When falling out, it can happen that the part rotates about the screw axis of the fastening screw and can then no longer be tightened exactly. This danger is eliminated by the present invention.

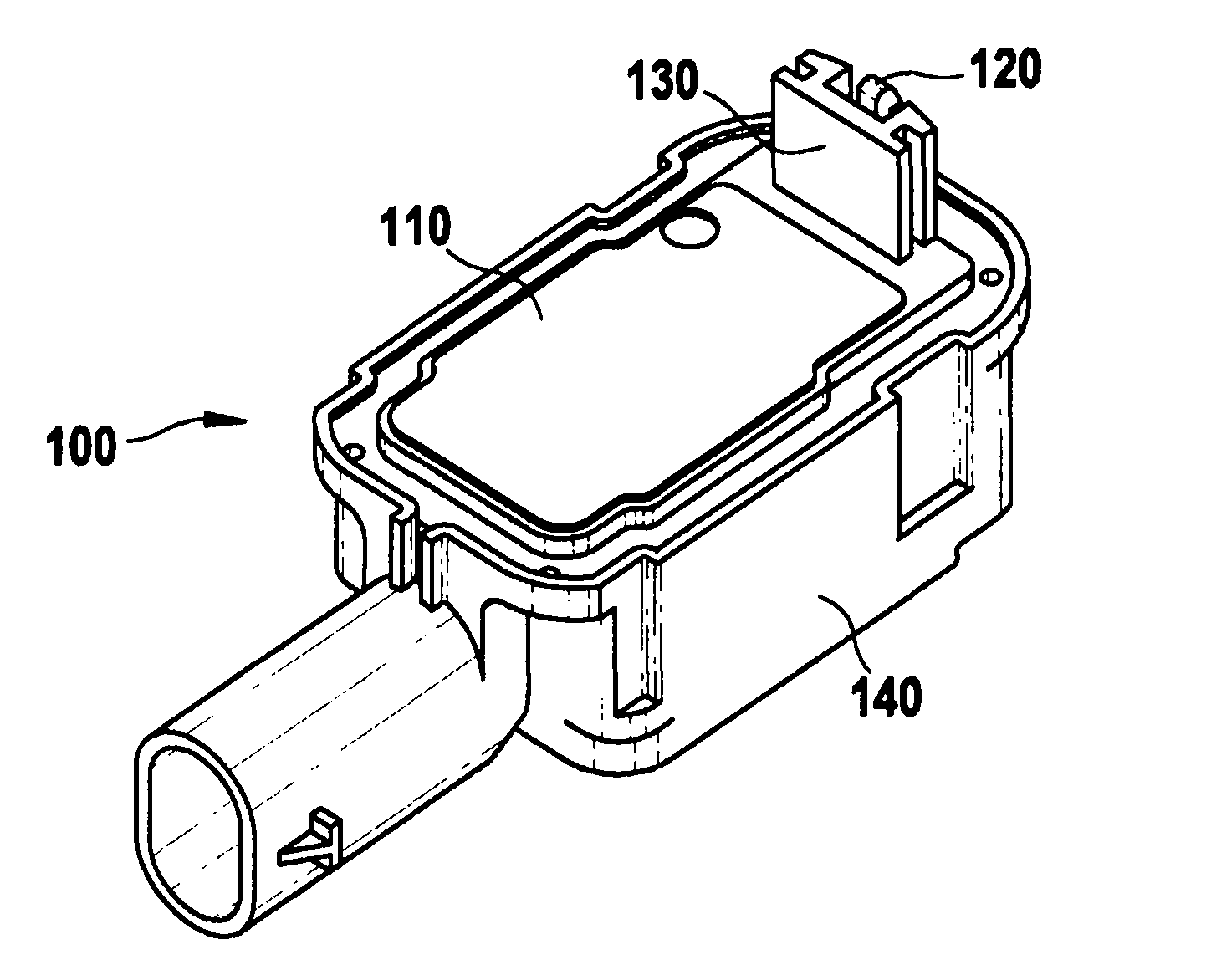

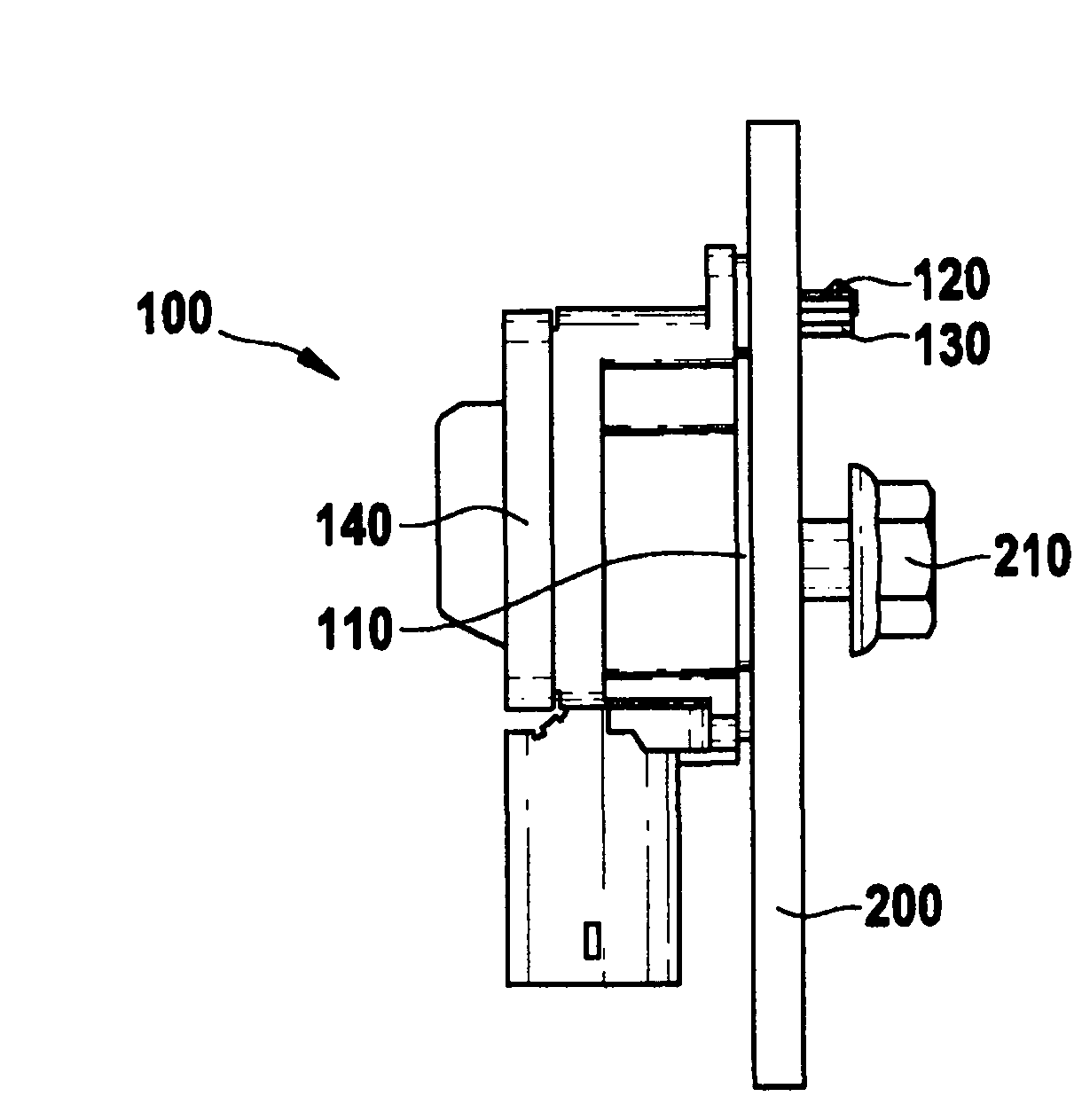

[0032] exist figure 1 , a perspective view of an embodiment of the present invention is shown. The fixing element 100 comprises a support element 110, for example constituted by a support plate, which lies flat against the wall when the fixing device 100 is fixed in a keyhole-shaped cutout in a wall or bracket. The support element 110 should in this case cover the edge of the narrower part (hole) of the keyhole-shaped cutout, whereby not only the support element 110 can be supported on the wall, but...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com