Electric spring operating mechanism

A technology of operating mechanism and electric spring, which is applied in the direction of the power device inside the switch, can solve the problems of high processing cost of the base and the shell, fast closing speed, deformation of the splint, etc., to reduce the processing range and processing requirements, The effect of reducing the operating work of the spring and stabilizing the performance

Inactive Publication Date: 2011-06-29

SHANGHAI SIEYUAN HIGH VOLTAGE SWITCHGEAR

View PDF6 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

After searching the existing technology, it is found that the overall dimensions of the existing electric spring operating mechanism are too large

In addition, the existing operating mechanism adopts the principle of quick opening and quick closing, that is, a symmetrical form, that is, the opening and closing are all completed by releasing energy from the spring. This method is not conducive to the opening operation. In order to be able to open the gate, the spring force must be increased. , which causes the closing speed to be too fast and the vibration to increase, which is not conducive to the mechanical life of the switch body and the mechanism

At the same time, the processing cost of the existing base and shell is high, and the assembly efficiency is low due to inaccurate positioning and splint deformation.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

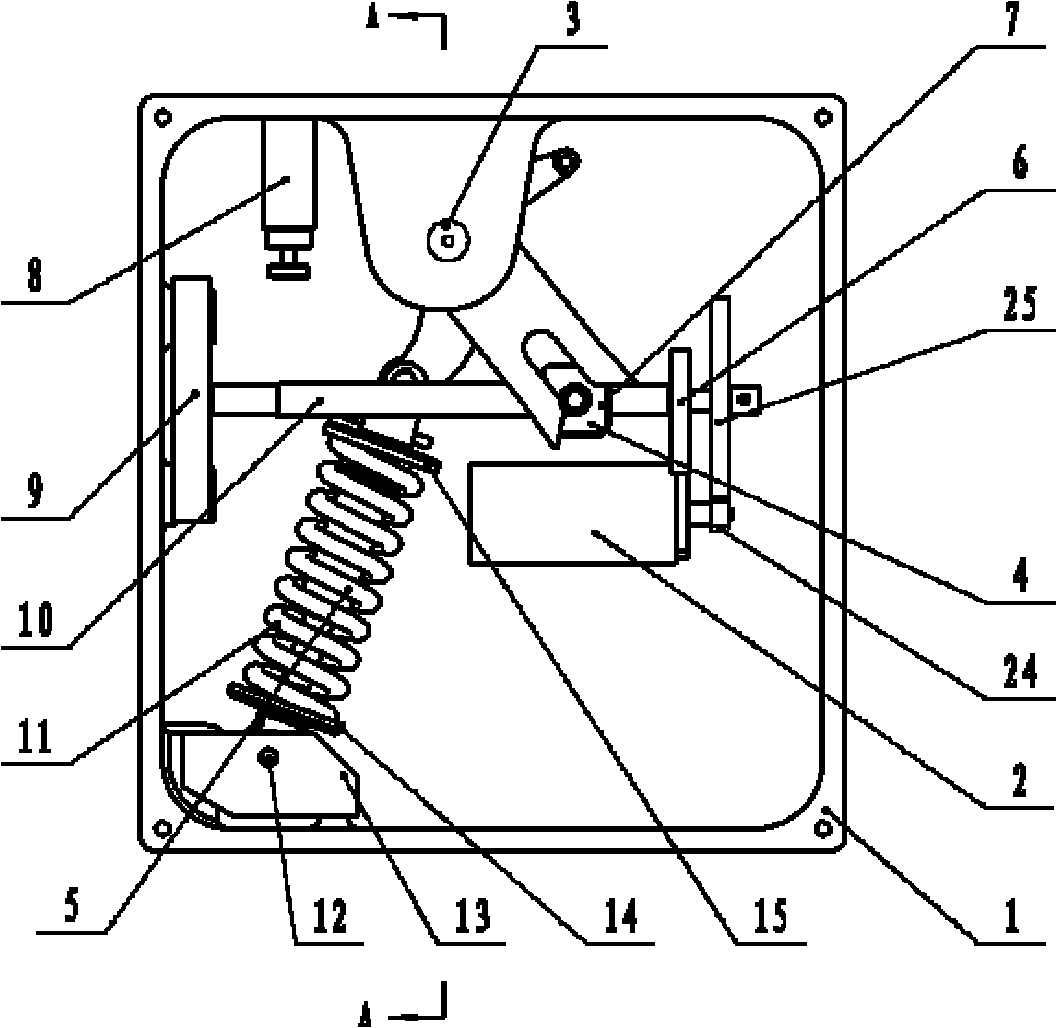

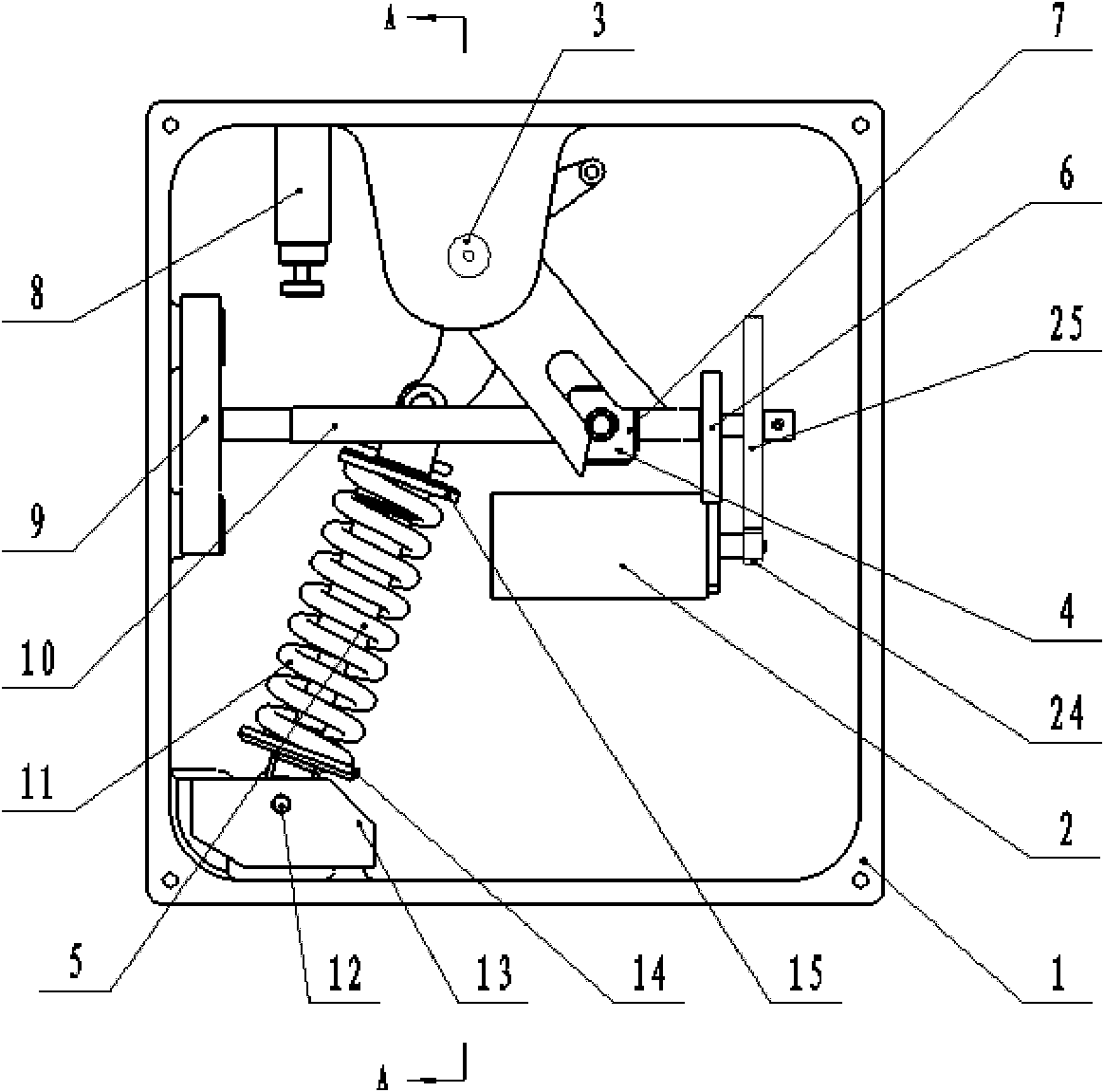

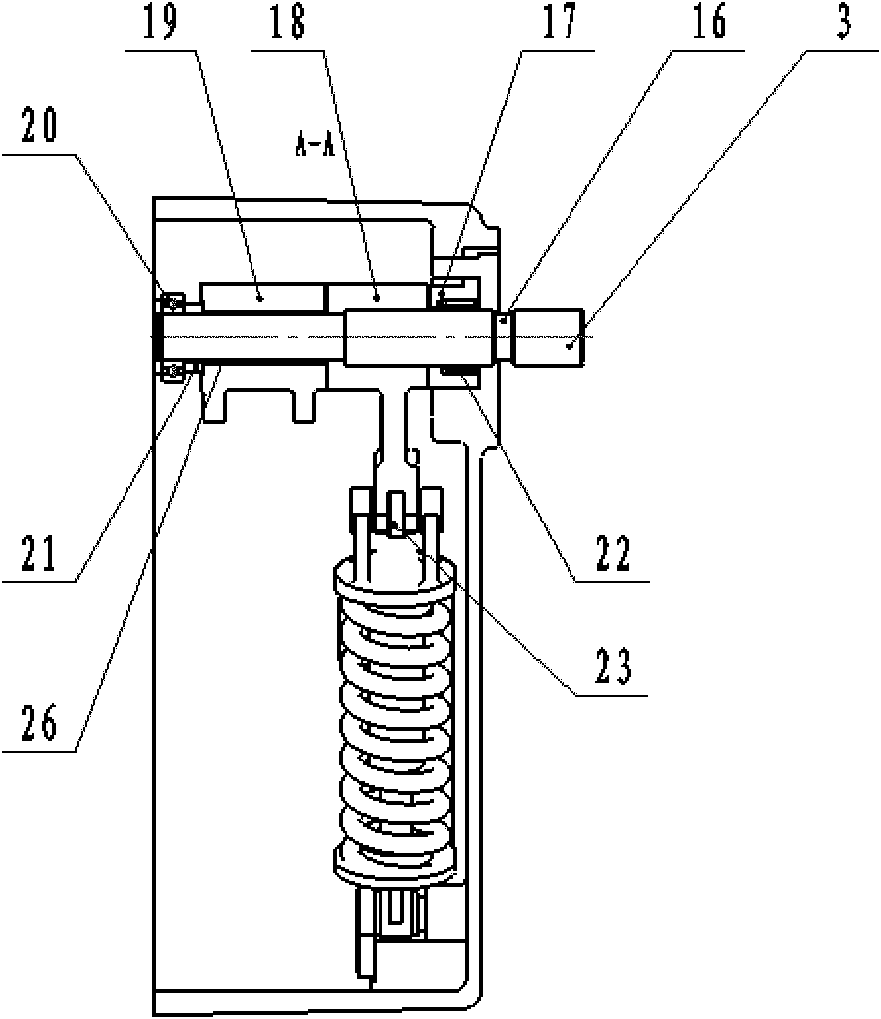

The invention relates to an electric spring operating mechanism belonging to the technical field of a high-voltage power switch. The electric spring operating mechanism comprises a base, a motor, a transmission shaft assembly, a lead screw assembly and a spring assembly, wherein the transmission shaft assembly is fixedly arranged on the base; one end of the spring assembly is connected with the base, and the other end of the spring assembly is connected with the transmission shaft assembly; both ends of the lead screw assembly are fixedly arranged on the base and are connected with the transmission shaft assembly; and the motor is connected with the lead screw assembly in a meshing mode. The invention satisfies the driving task of a fast grounding switch in a GIS (Gas Insulated Switchgear) so as to achieve the functions of fast switching-on and slow switching-off of the fast grounding switch. Besides, the electric spring operating mechanism has the advantages of simple structure, beautiful appearance, stable performance and high reliability.

Description

Electric Spring Operating Mechanism technical field The invention relates to a device in the technical field of high-voltage power switches, in particular to an electric spring operating mechanism. Background technique The grounding switch driven by the electric spring mechanism can make the switch contacts move quickly, so as to realize the function of closing the short-circuit current. It is an indispensable device for high-voltage switchgear. The basic principle is that the motor drives the spring to store energy after being decelerated by the deceleration device, and the stored energy spring releases energy after passing the dead point to drive the switch contact to move quickly. After searching the prior art, it is found that in the existing electric spring operating mechanism, the overall external dimension is too large. In addition, the existing operating mechanism adopts the principle of quick opening and quick closing, that is, a symmetrical form, that is, the o...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01H3/30

Inventor 崔九同高辉高国宪何海波

Owner SHANGHAI SIEYUAN HIGH VOLTAGE SWITCHGEAR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com