Electronic control transmission sensing fine turning intelligent oil feeder

A fuel feeder and sensor technology, applied in the direction of machines/engines, etc., can solve problems such as unsatisfactory, narrow adjustment range of air-fuel ratio, matching, correction, and adjustment of air-fuel ratio, so as to reduce the difficulty of installation and disassembly and save target power , to avoid the effect of signal disorder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

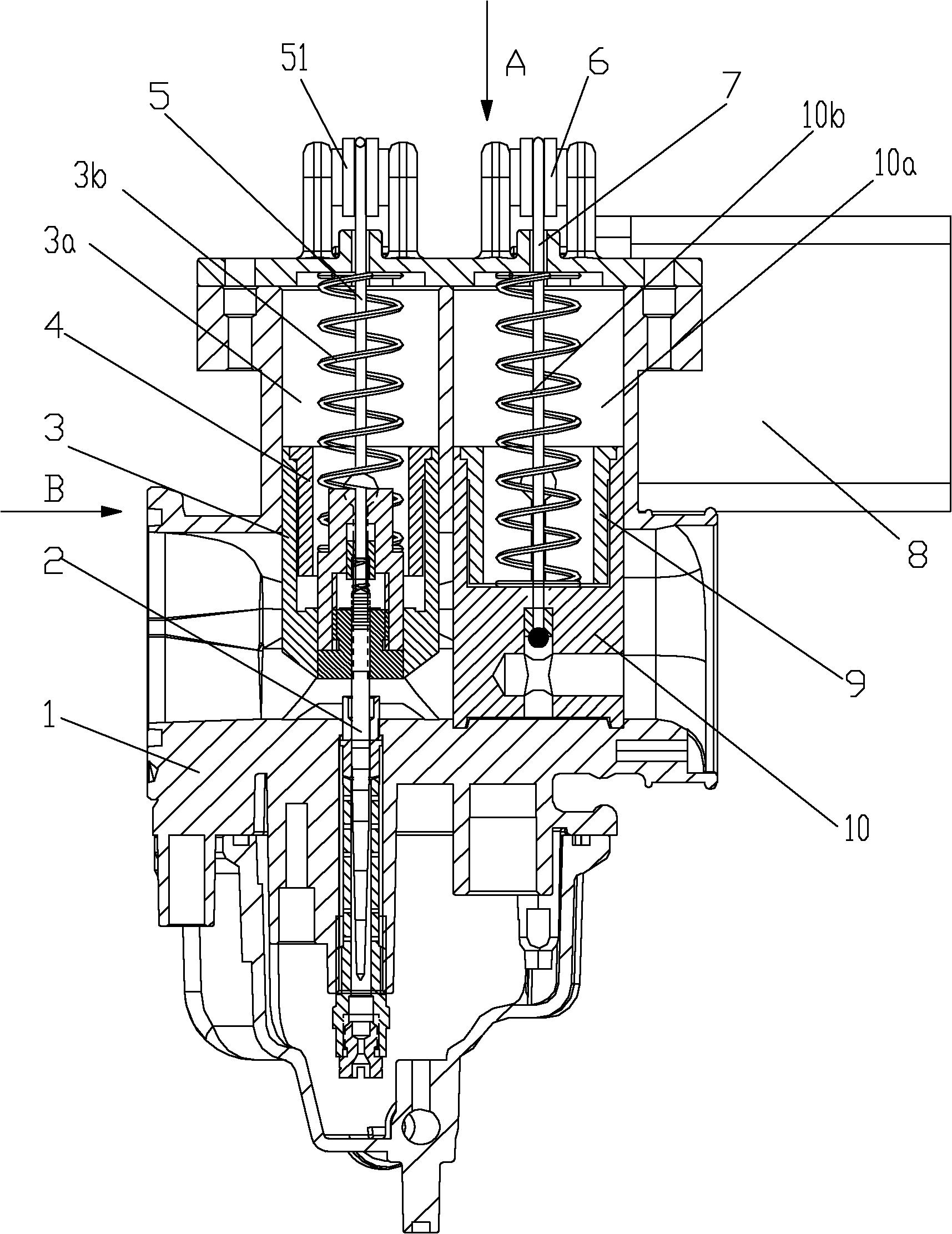

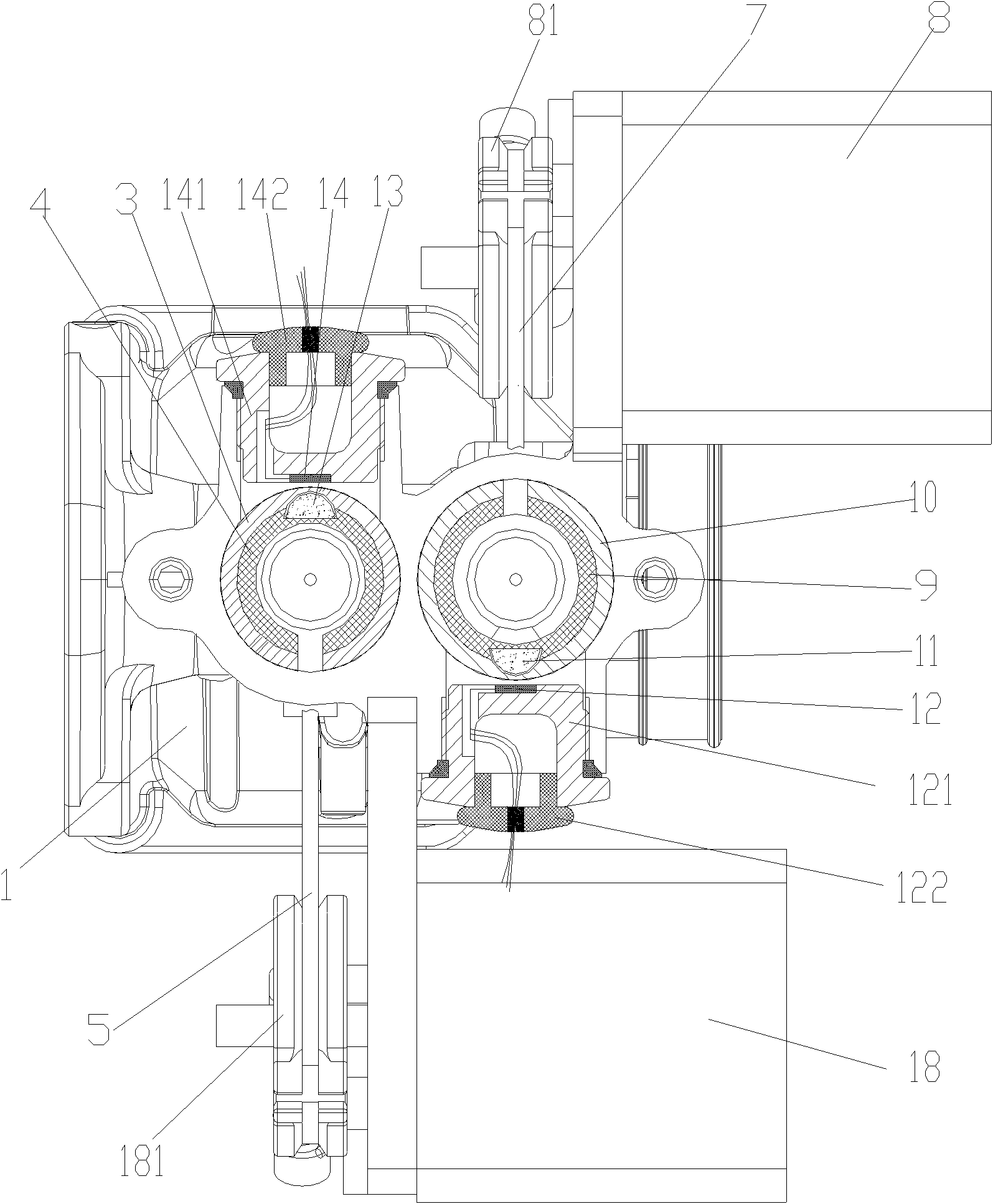

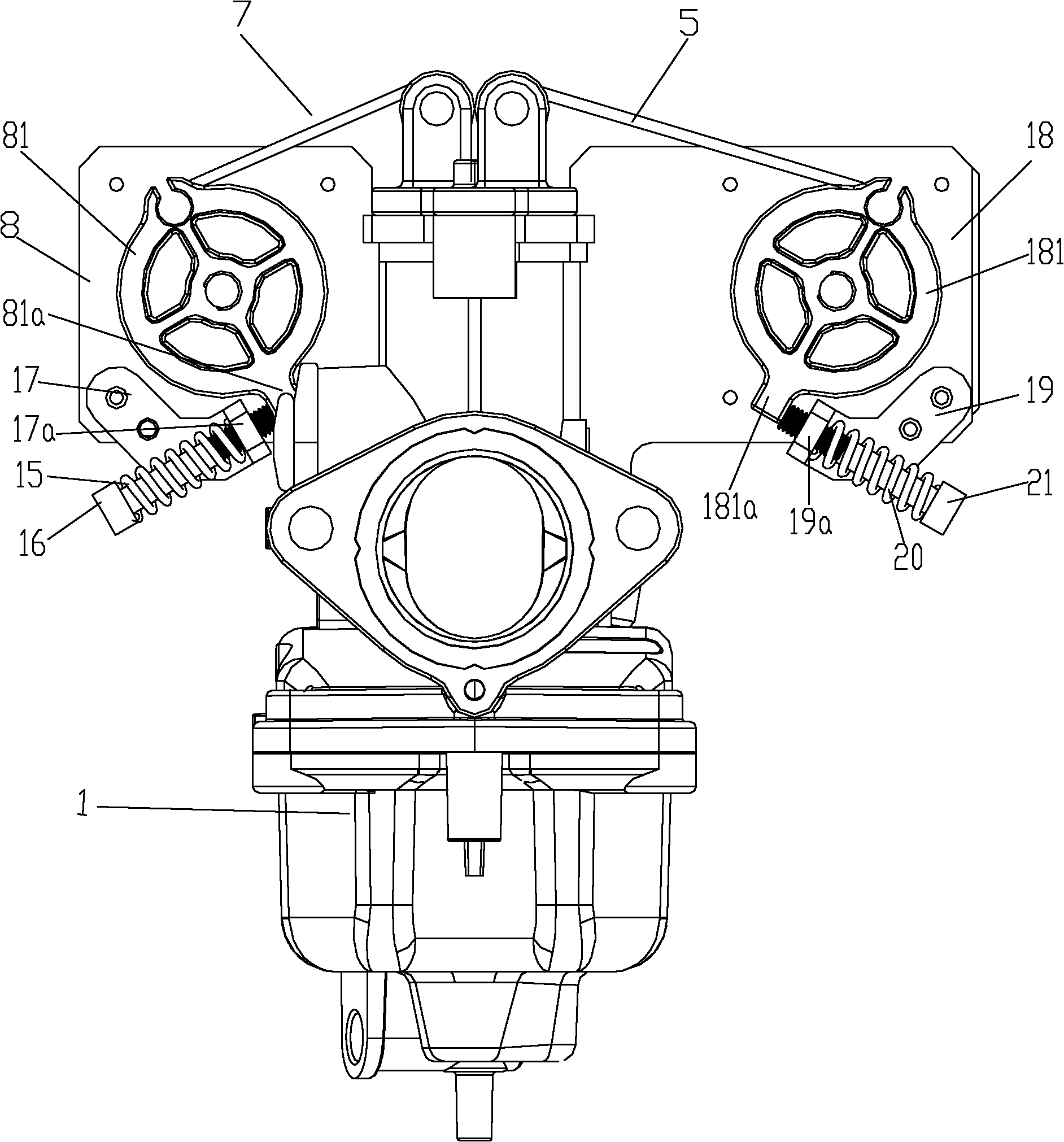

[0043] figure 1 It is a schematic diagram of the structure of the present invention, figure 2 for figure 1 Partial sectional view of the view along direction A, image 3 for figure 1 View along direction B, Figure 4 It is a block diagram of the control principle of the present invention, as shown in the figure: the electronically controlled transmission sensing fine-tuning intelligent oil feeder of this embodiment includes the oil feeder body 1 and the throttle valve and oil inlet system arranged on the oil feeder body, The oil inlet system includes the main nozzle, the oil needle 2 and the oil needle plunger 3 fixedly connected with the oil needle 2 in the axial direction. Throttle spool 10 reciprocating throttle spool cavity 10a; the oil needle plunger 3 is provided with an oil needle return spring 3b to return it, and the throttle spool 10 is provided with a throttle return spring 10b;

[0044] Also included is an automatic control system comprising:

[0045] The oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com