Manual-control drum-type transmission sensing fine tuning intelligent oil feeder

A technology of fuel supply and sensing, which is applied in the field of fine-tuning intelligent fuel supply of manual cylinder type transmission sensor, which can solve problems such as unsatisfactory, narrow air-fuel ratio adjustment range, and impact on emissions, so as to reduce the difficulty of installation and disassembly , Avoid signal confusion and save fuel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

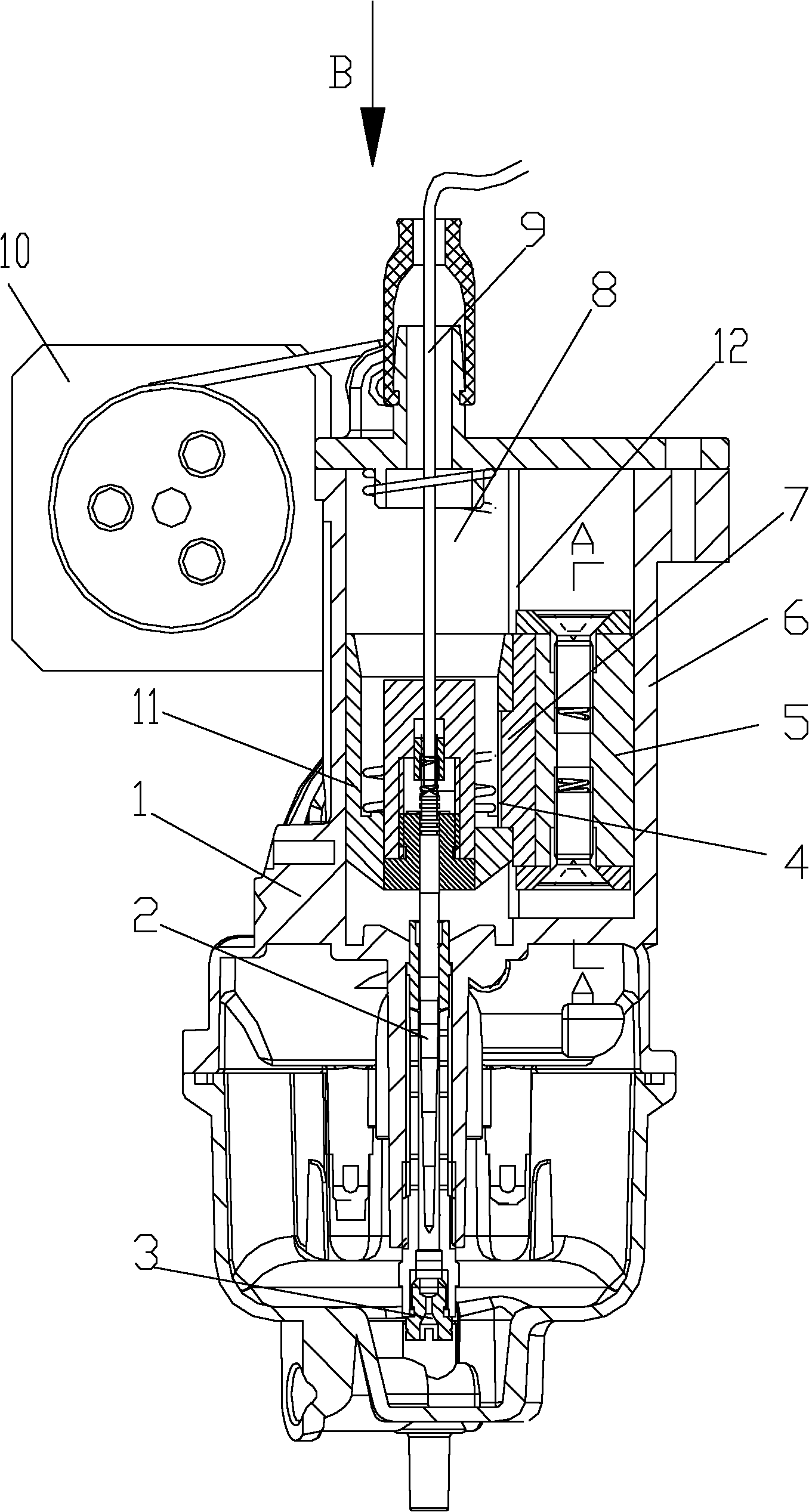

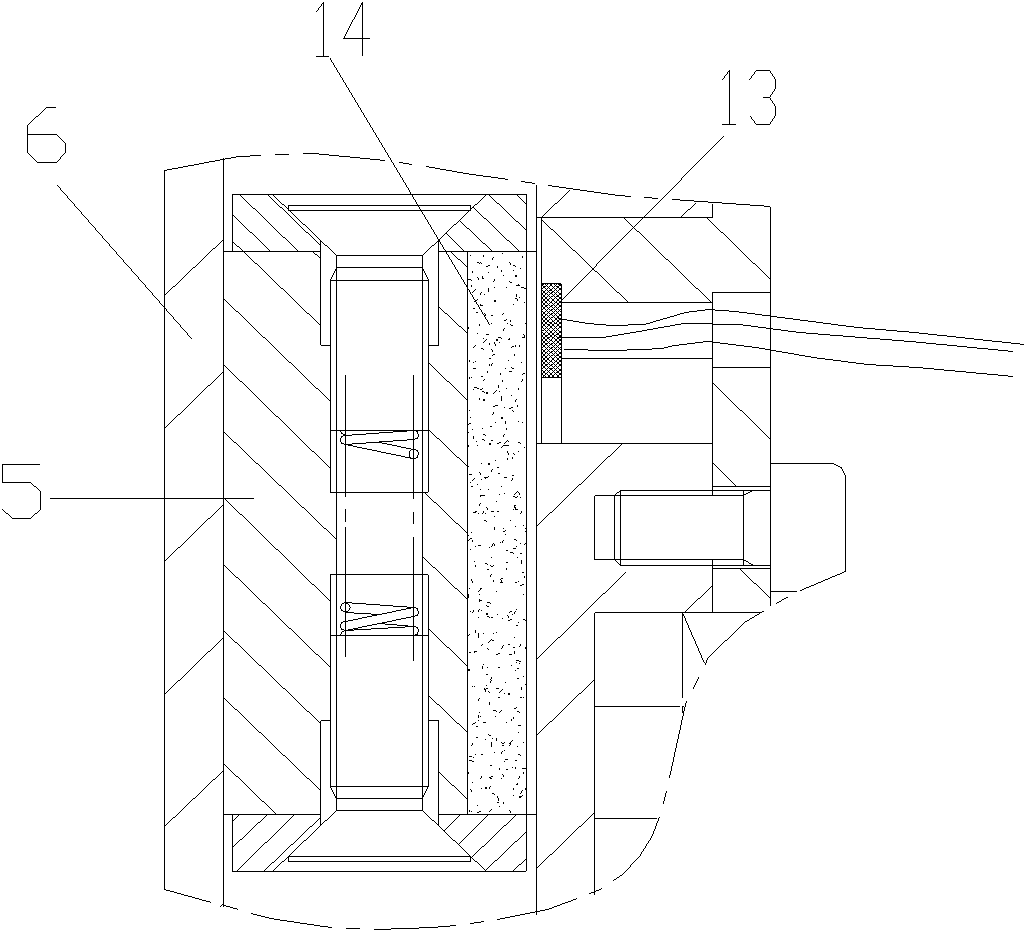

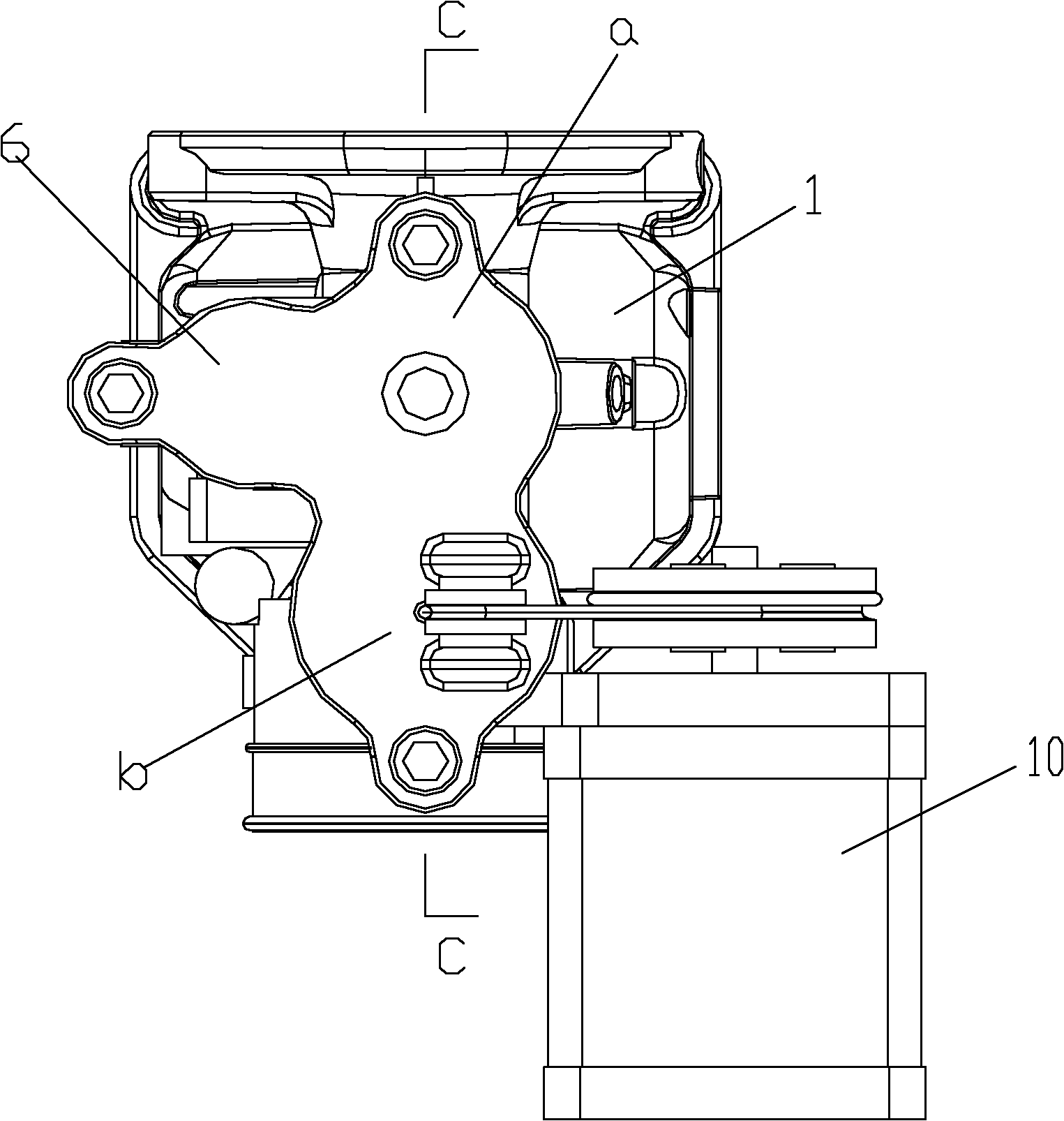

[0048] figure 1 It is a structural schematic diagram of Embodiment 1 of the present invention, figure 2 for figure 1 Sectional view along A-A, image 3 for figure 1 View along direction B, Figure 4 for image 3 The sectional view along C-C is as shown in the figure: the electric cylinder type transmission sensor fine-tuning intelligent oil supply device of this embodiment includes the oil supply body 1 and the throttle valve and oil inlet system arranged on the oil supply body 1, The oil inlet system includes a main nozzle 3, an oil needle 2 and an oil needle plunger 11 fixedly connected to the oil needle 2 in the axial direction. The oil needle plunger guide chamber 8 (direction indicated by a in the figure) and the throttle valve core guide chamber 26 (direction indicated by b in the figure) for the throttle valve core 15 to reciprocate in the axial direction; same as the prior art, the oil needle Both the plunger 11 and the throttle valve core 15 are provided with a...

Embodiment 2

[0058] Figure 5 It is a schematic structural diagram of Embodiment 2 of the present invention, Image 6 for Figure 5 View along direction D, Figure 7 for Image 6 Sectional view along E-E, Figure 9 It is a block diagram of the control principle of the present invention, as shown in the figure: the difference between this embodiment and the first embodiment is that the automatic control system also includes a throttle opening detection device, and the throttle opening detection device includes a valve fixed on the oil supply body The guide cylinder II 21, the guide plunger II 18 arranged in the guide cylinder II 21 and slidingly matched with it in the axial direction, and the throttle opening detection element for detecting the sliding displacement of the guide plunger II 18; the throttle opening The throttle opening degree signal detected by the degree detection element is input into the electronic control unit 25; the guide plunger II 18 is fixedly matched with the th...

Embodiment 3

[0063] The difference between this embodiment and Embodiment 1 is that the oil needle displacement detection element is a potentiometer type displacement sensor 24, and the potentiometer type displacement sensor 24 is fixedly arranged in the guide cylinder 16, and the potentiometer type displacement sensor 24 The telescopic probe 23 coaxially withstands the guide plunger 15, and is located between the guide plunger 15 and the potentiometer type displacement sensor 24, and the telescopic probe 23 is provided with a return spring 27;

[0064] Compared with Embodiment 1, this embodiment only has a different structure of the oil needle displacement detection element, and the rest of the structures are the same, so the reference signs of the same parts as Embodiment 1 are completely the same; this embodiment adopts potentiometer displacement The sensor has simple structure, large output signal, convenient use and low price.

[0065] The control principle of this embodiment is the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com