Manual-control driving and sensing precision fine-tuning intelligent oil feeder

A fuel supply and sensing technology, applied in the field of manual transmission sensing fine-tuning intelligent fuel supply, can solve the problems of increasing fuel consumption and emission, unsatisfactory, matching, correcting, adjusting air-fuel ratio, etc., so as to reduce emissions , the effect of efficient operation and steady-state operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

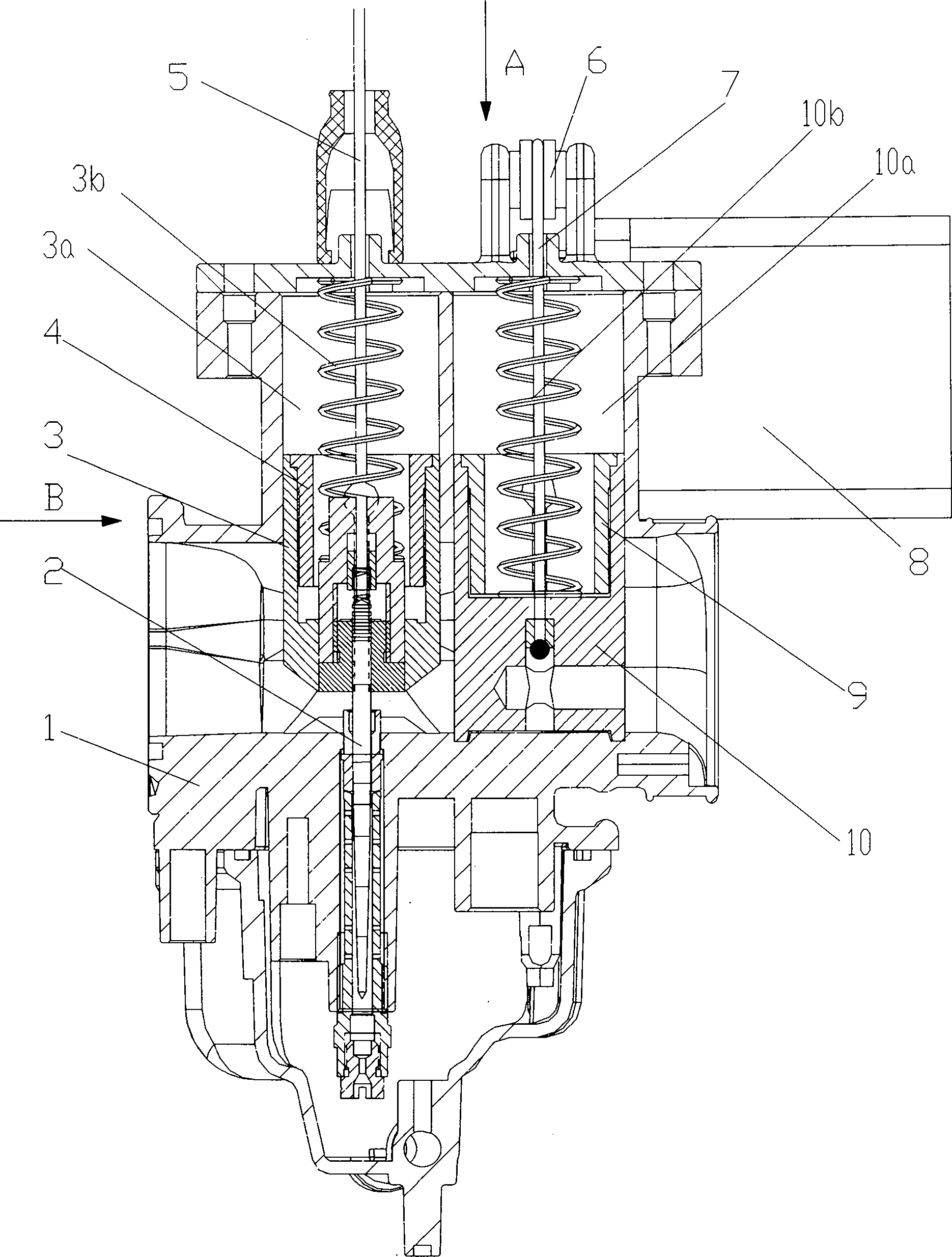

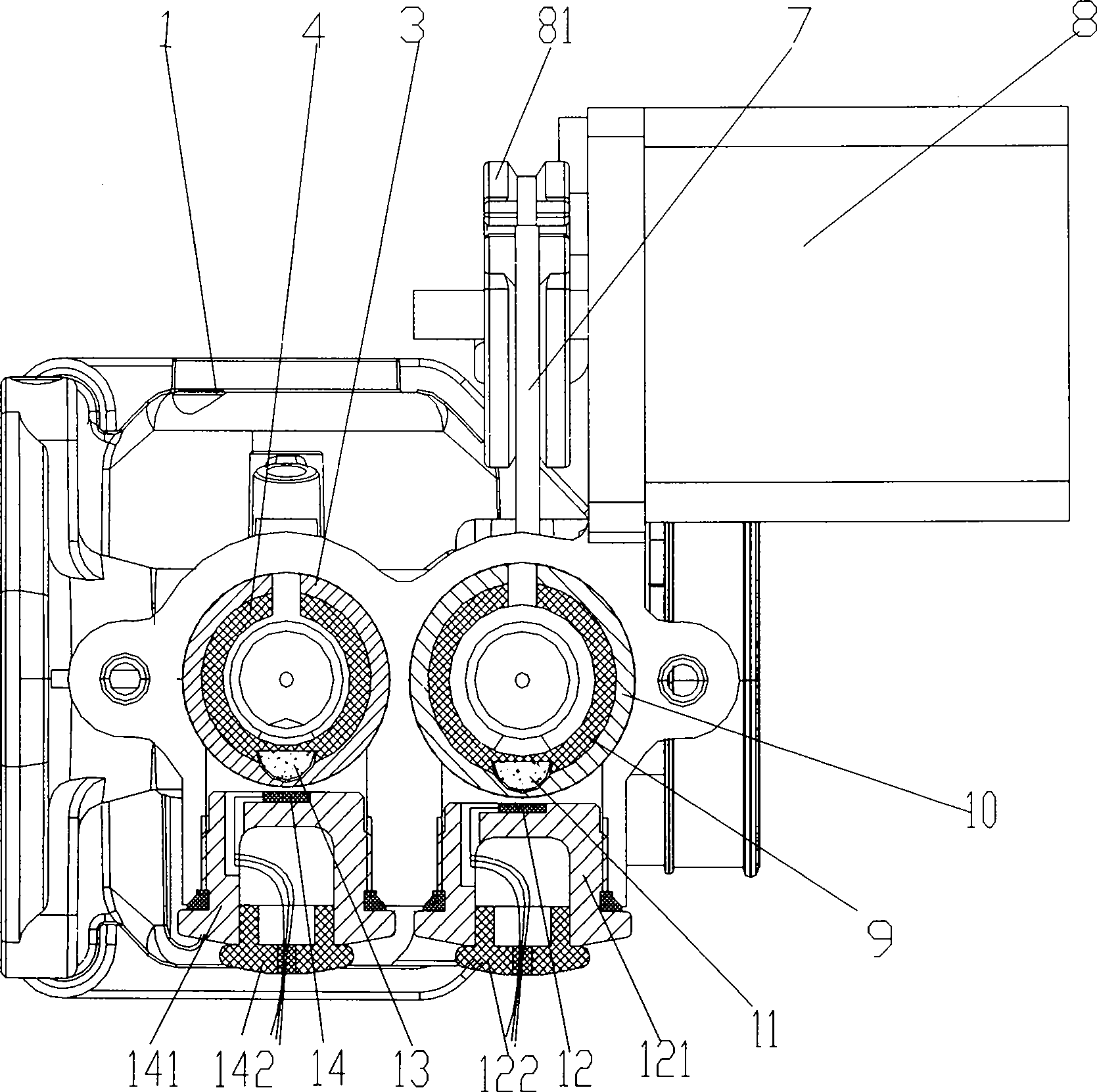

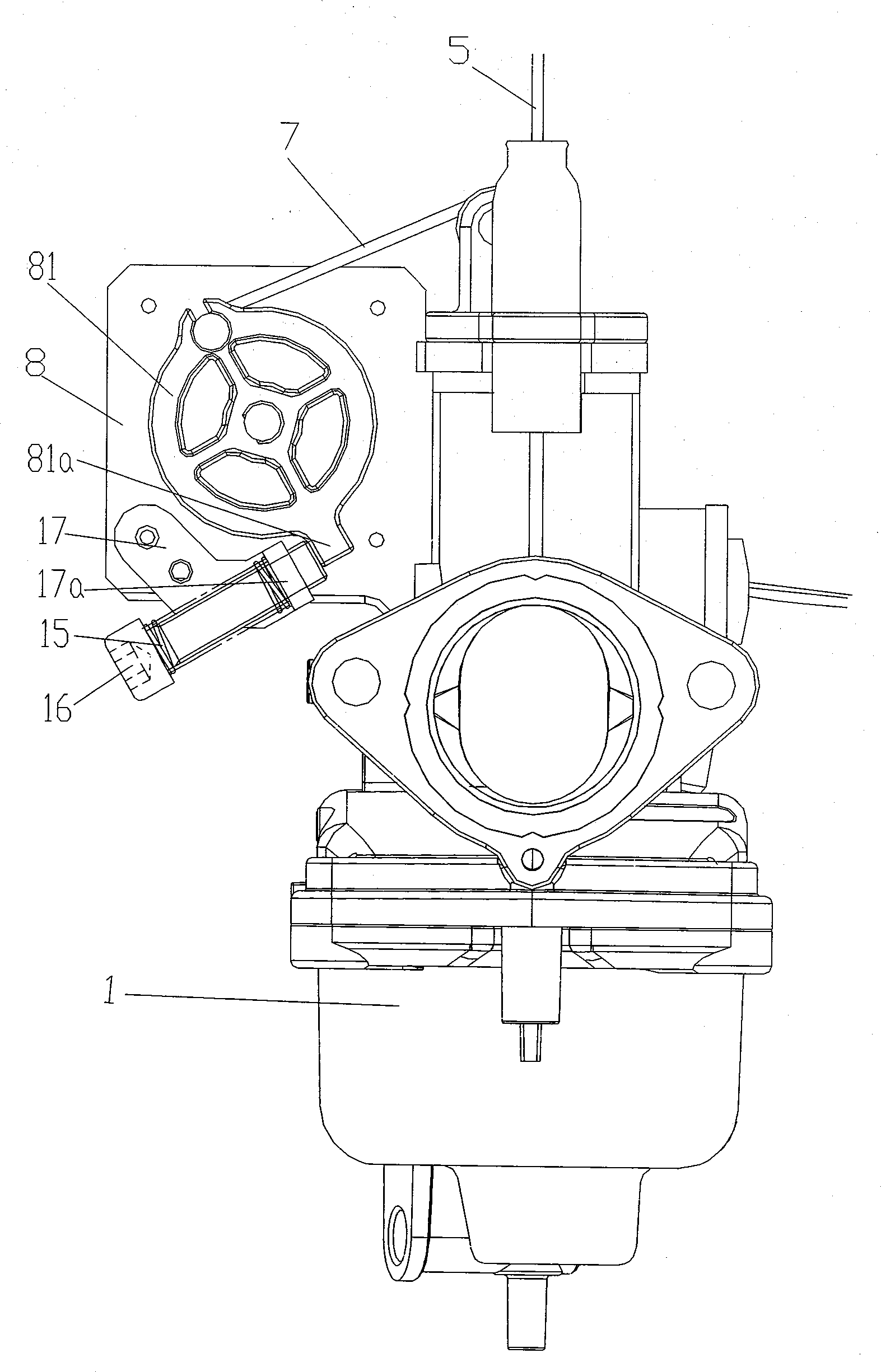

[0040] figure 1 It is a schematic diagram of the structure of the present invention, figure 2 for figure 1 Partial sectional view of the view along direction A, image 3 for figure 1 View along direction B, Figure 4It is a block diagram of the control principle of the present invention, as shown in the figure: the manual transmission sensor fine-tuning intelligent oil feeder of this embodiment includes the oil feeder body 1 and the throttle valve and oil inlet system arranged on the oil feeder body, The oil inlet system includes the main nozzle, the oil needle 2 and the oil needle plunger 3 fixedly connected with the oil needle 2 in the axial direction. Throttle spool 10 reciprocating throttle spool cavity 10a; the oil needle plunger 3 is provided with a manual drive cable 5 and an oil needle return spring 3b to return it, and the throttle spool 10 is provided with a throttle return Spring 10b; as shown in the figure, the oil needle plunger 3 is manually controlled by m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com