Method for measuring relative density of naturally-graded coarse particle dam construction material

A technology of relative density and coarse-grained materials, which is applied in the field of measuring the maximum dry density of the original graded coarse-grained dam body, can solve problems in the use of density indicators, difficulty in popularizing engineering applications, and failure to solve problems such as dry density scaling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

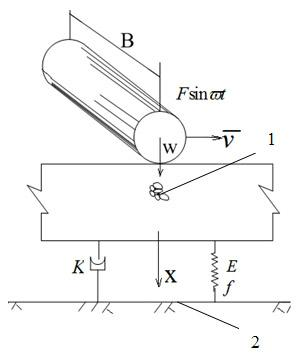

[0077] In this implementation case, YZT16 vibrating roller was used for rolling test, and the specific parameters are shown in Table 1.

[0078]

[0079] Table 1

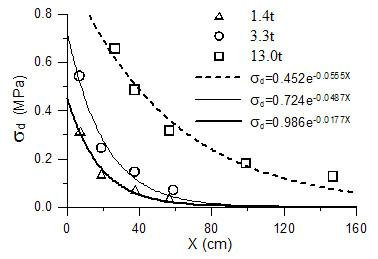

[0080] 1. In the paving and rolling test site, the coarse-grained dam materials that need to be rolled are paved and leveled, and the average minimum dry density ρ is measured by the irrigation method dmin 1.783g / cm 3 .

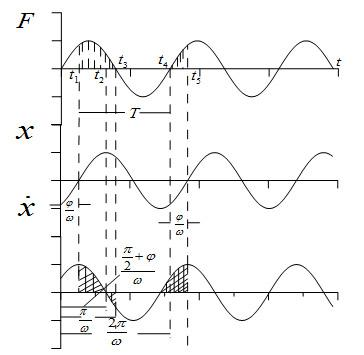

[0081] 2. According to formula (4), when When approximately equal to ω, α=π / 2, at this time, the structure resonates, and the coarse-grained soil layer obtains the best vibration effect, then the energy calculation of the coarse-grained soil layer per unit area given by the vibrating roller driving once can be obtained from formula (7) The formula simplifies to:

[0082] E = E 0 · t T · 1 BL = [ 2 W + π ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com