Telescopic tunneling immediate support device

A support device and telescopic technology, which is applied to mine roof supports, mining equipment, earthwork drilling, etc., can solve the problems of continuous roof connection or poor roof connection ability, and improve the quality of support and the efficiency of tunneling operations. Improve the start-up rate and enhance the effect of reasonable operation ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

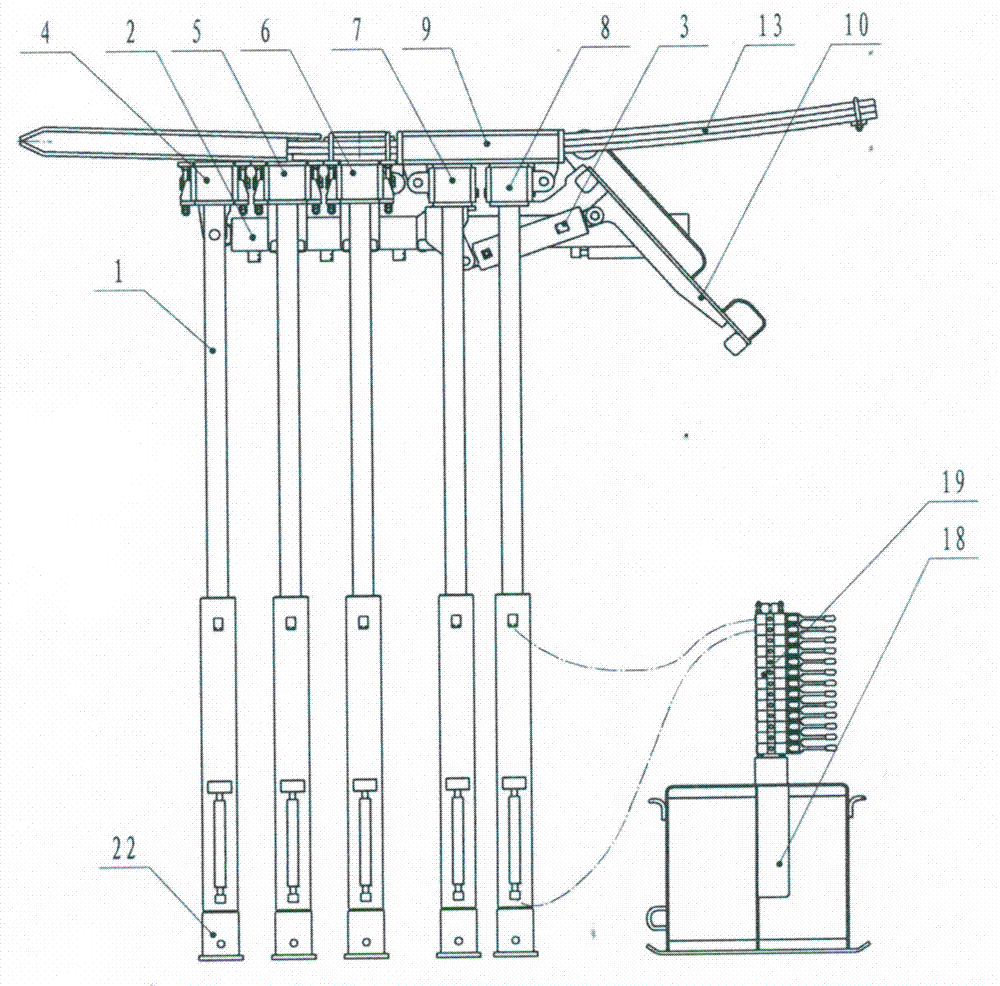

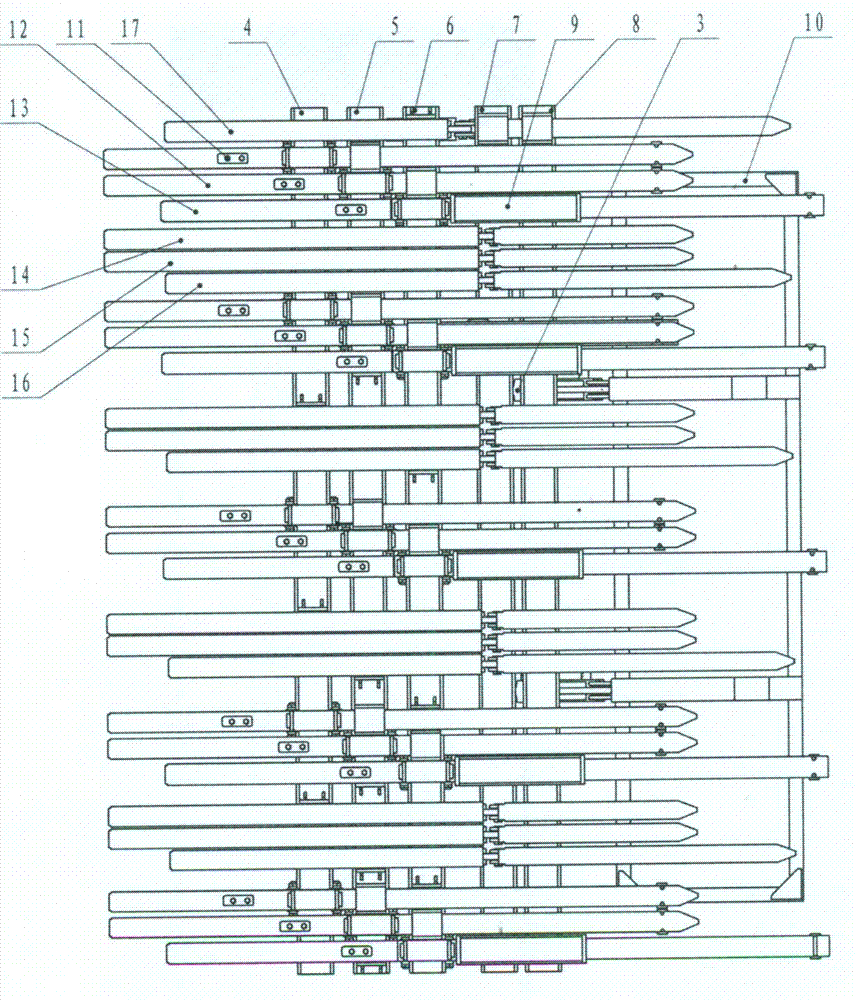

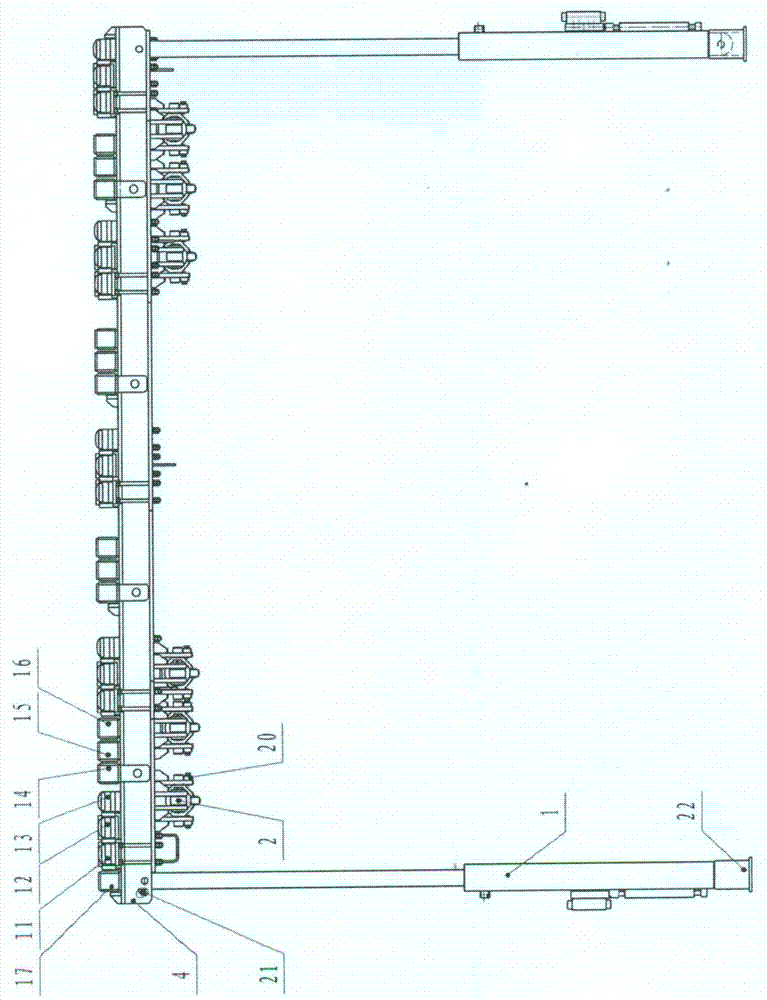

[0017] according to Figure 1~4 The specific structure of the present invention will be described in detail. The telescopic tunneling and timely support device includes a hydraulic column 1, a beam supported by the column head of the hydraulic column 1, and a beam assembled on the beam. The column bottom of the hydraulic column 1 is provided with a separate base 22 connected to the hydraulic system 19 to prevent the hydraulic column 1 from sinking into the bottom plate. The hydraulic system 19 is fixed by the valve group trailer 18 and other components. The above-mentioned cross beams include the front cross beam 4, the middle cross beam 5, the rear cross beam 6, the main support cross beam 7 and the auxiliary support cross beam 8 arranged parallel to each other; the cross beams include the front elastic cross beams 11 and the middle elastic cross beams arranged parallel to each other and perpendicular to the cross beams. Along beam 12, a rear elastic beam 13, a front rigid b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com