Twin-wire dual-drive arc welding wire feeder

A wire feeding device and dual-drive technology, applied in arc welding equipment, welding equipment, manufacturing tools, etc., can solve the problem of uneven wire feeding speed of two welding wires, and achieve uneven wire feeding speed, consistent driving speed, and welding smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention is described in detail below in conjunction with embodiment and accompanying drawing.

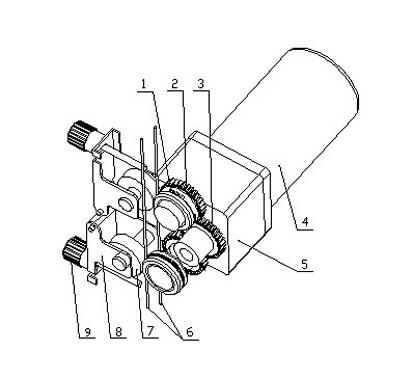

[0011] see figure 1 , the arc welding dual-wire dual-drive wire feeding device provided in this embodiment consists of a wire feed wheel 1, a wire feed gear 2, an intermediate gear 3, a motor 4, a reducer 5, a pinch wheel 7, a pinch wheel bracket 8, a spring The pressing device 9 constitutes. The intermediate gear 3 is connected to the output shaft of the reducer 5, and transmits the power to the two wire feed rollers 1 respectively through the two meshed wire feed gears 2, and each wire feed roller 1 is stacked with each wire feed gear 2. They are fixed together, and the upper and lower wire feed rollers 1 are staggered and installed front and back.

[0012] In this embodiment, each of the pressing wheels 7 is mounted on a pressing wheel bracket 8, and each pressing wheel bracket 8 is equipped with a spring pressing device 9 respectively. The pinch wheel 7 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com