Damping pressure reducing valve

A technology of a pressure reducing valve and a pressure reducing valve core, which is applied in the field of vibration reduction and pressure reducing valves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

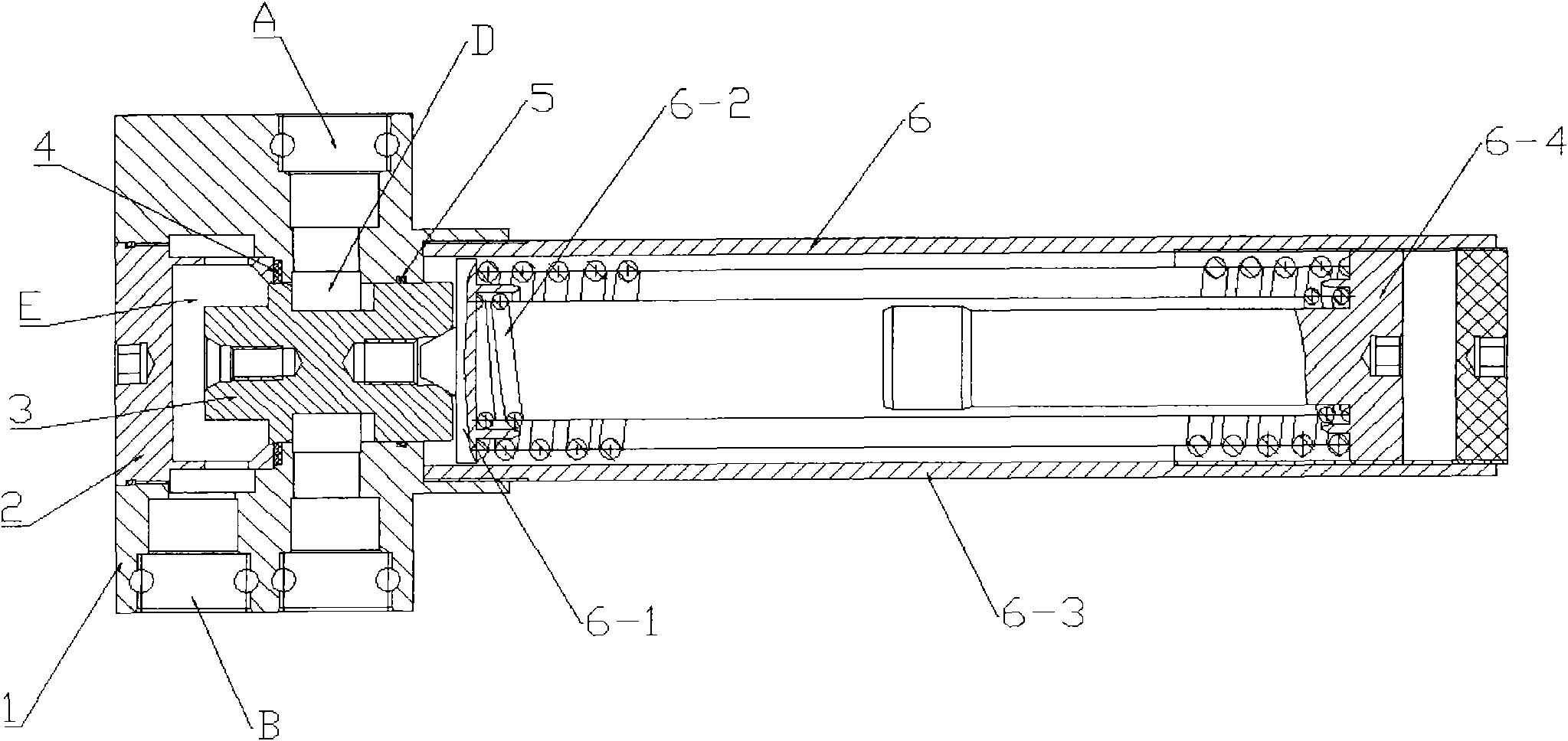

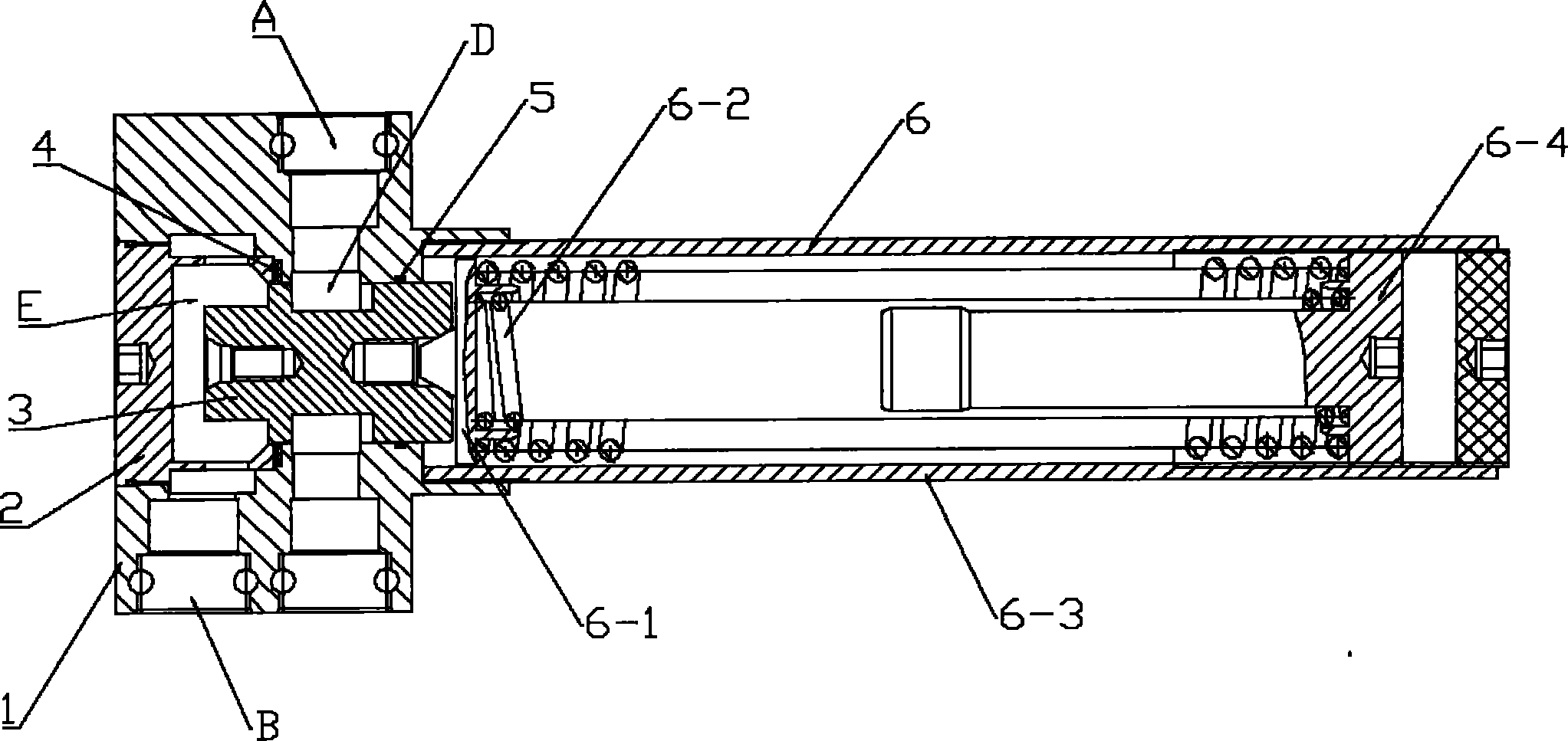

[0024] See attached figure 1 , which describes a preferred embodiment of the damping and pressure reducing valve according to the present invention. It includes a pressure reducing valve body, a pressure plug, a vibration reduction and pressure relief valve core, a pressure relief valve seat, a pressure relief sealing ring, and a pressure relief spring device. The pressure relief valve body has a pressure relief hole, and the vibration reduction and pressure relief valve core Installed in the decompression hole and can move along the axial direction of the decompression hole, an annular groove is arranged in the decompression hole, a decompression sealing ring is arranged in the annular groove, and the vibration reduction and decompression valve One end of the core has a cylindrical shaft section, the cylindrical shaft section cooperates with the pressure reducing valve body and the pressure reducing sealing ring to form a dynamic seal, and the cylindrical shaft section is con...

specific Embodiment 2

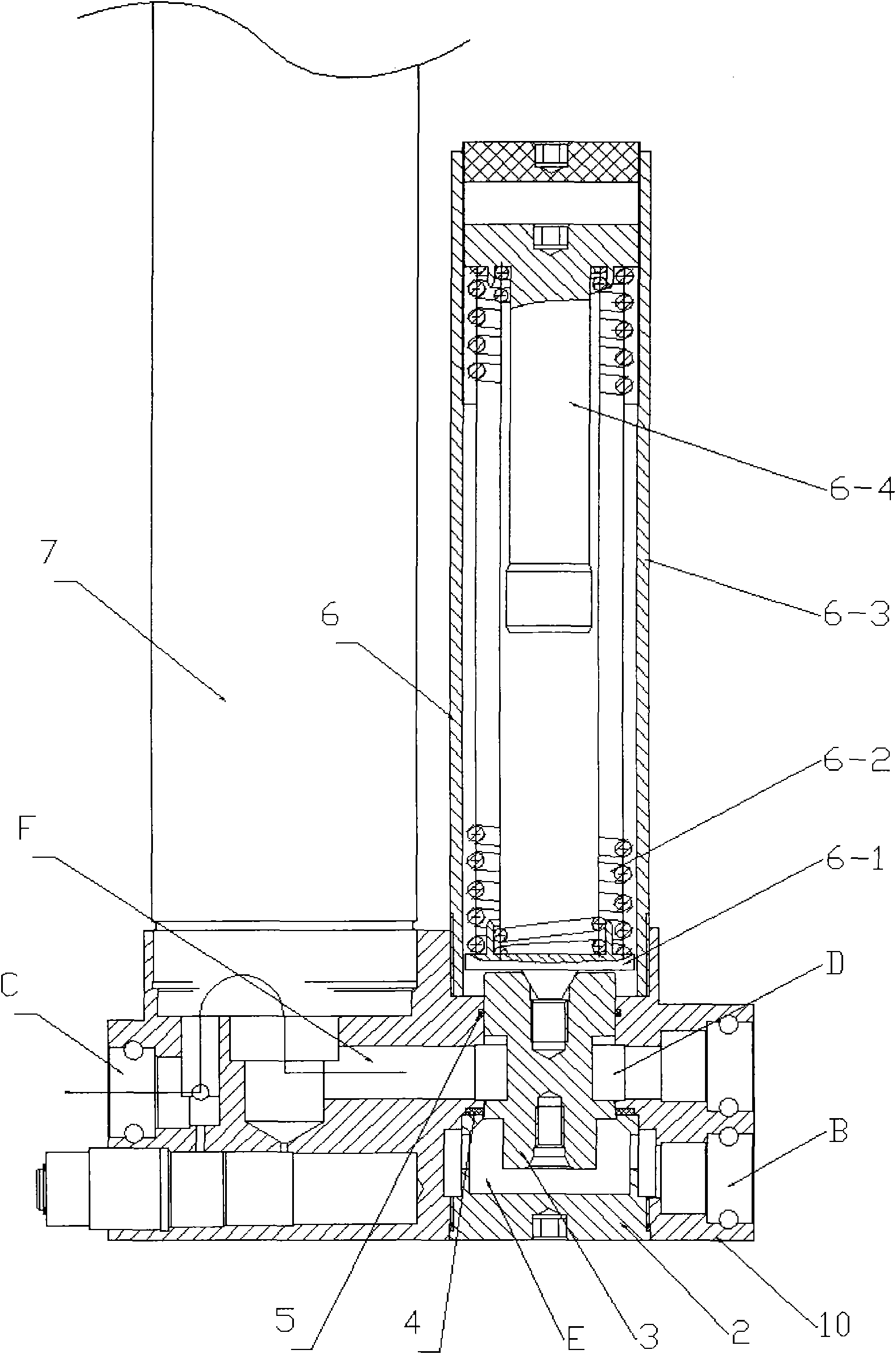

[0028] See attached figure 2 , which describes a preferred embodiment of the vibration damping and pressure reducing valve with filtering device according to the present invention. The basic structure of its decompression part is basically the same as that of the vibration-reducing pressure-reducing valve described in Embodiment 1, including the plugging of the vibration-reducing and reducing valve, the vibration-reducing and reducing valve core, the pressure-reducing valve seat, the pressure-reducing sealing ring, In addition to the decompression spring device, it also contains a vibration-reduction and pressure-relief valve body with a filter device and a filter device. The damping and pressure reducing valve body with filtering device has a pressure reducing hole, the vibration reducing and pressure reducing valve core is installed in the pressure reducing hole and can move along the axial direction of the pressure reducing hole, the pressure reducing valve core An annula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com