Precisely-driven vibrating platform

A vibration table and drive platform technology, which is applied in vibration testing, measuring devices, testing of machines/structural components, etc., can solve problems such as the difficulty of implementing micro-nano level vibration equipment, and achieve good rigidity, simple mechanism, and good reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

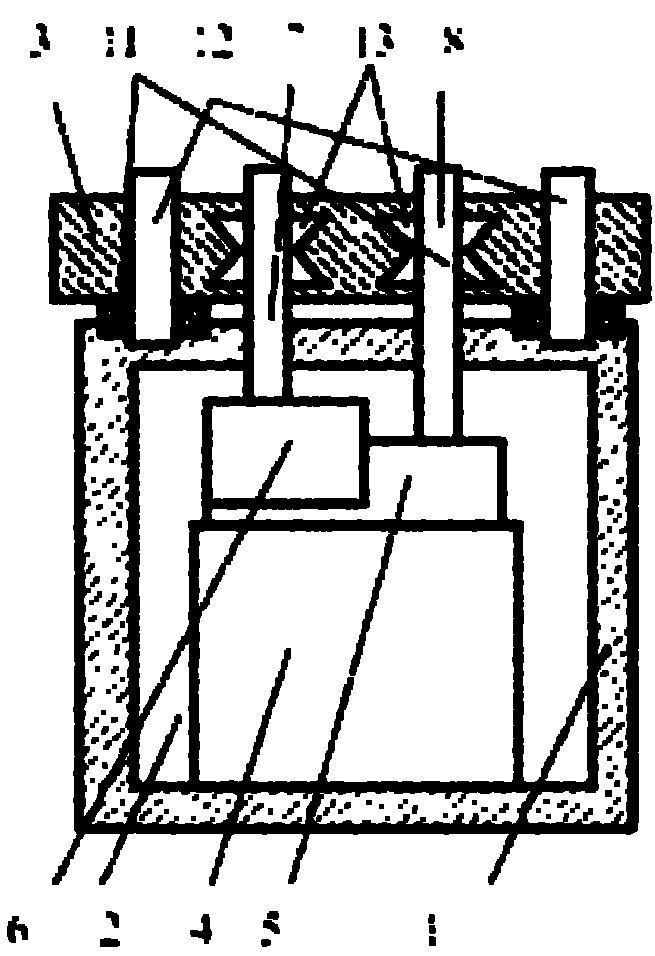

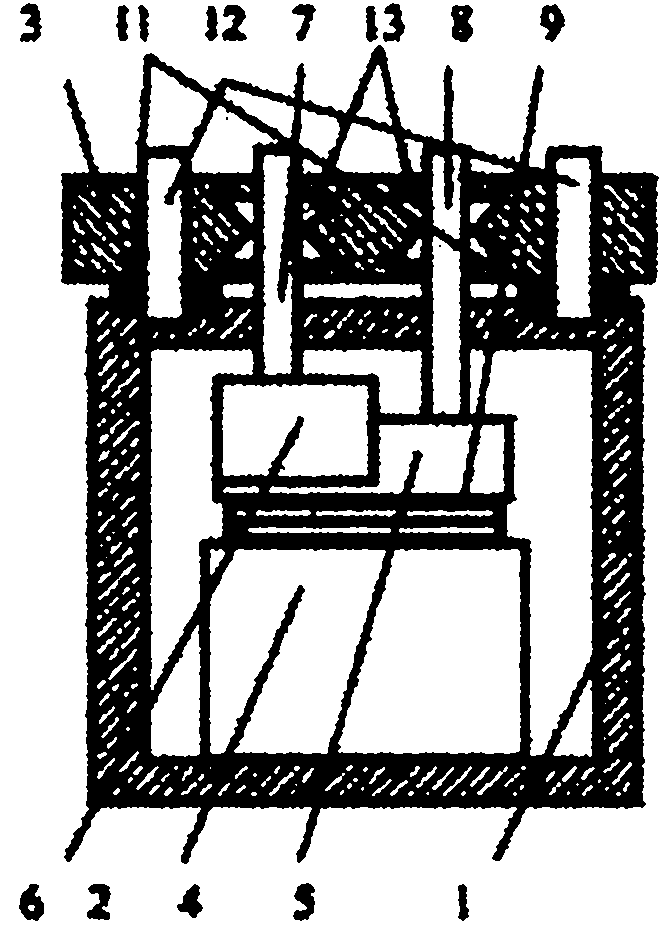

[0058] Such as Figure 6 As shown, the drive mechanism 2 is: the driver 4, the frame body and the amplified displacement output rod 7 connected thereto and the displacement output rod of the driver 4, wherein: the displacement output rod of the driver 4 is horizontally arranged on the elliptical structure In the frame type body and the driver 4 is located in the middle of the driver 4 displacement output rod, and the enlarged displacement output end rod 7 is arranged on the top of the frame type body of the oval structure.

[0059] The position where the displacement output rod of the driver 4 is in contact with the frame body is provided with snap rings;

[0060] Linear bearings are provided at the position where the amplified displacement output rod 7 and the displacement output rod of the driver 4 are in contact with the support frame.

[0061] The drive mechanism 2 can act to form as Figure 7 The shaker setup shown. The displacement produced by it to the displacement o...

Embodiment 3

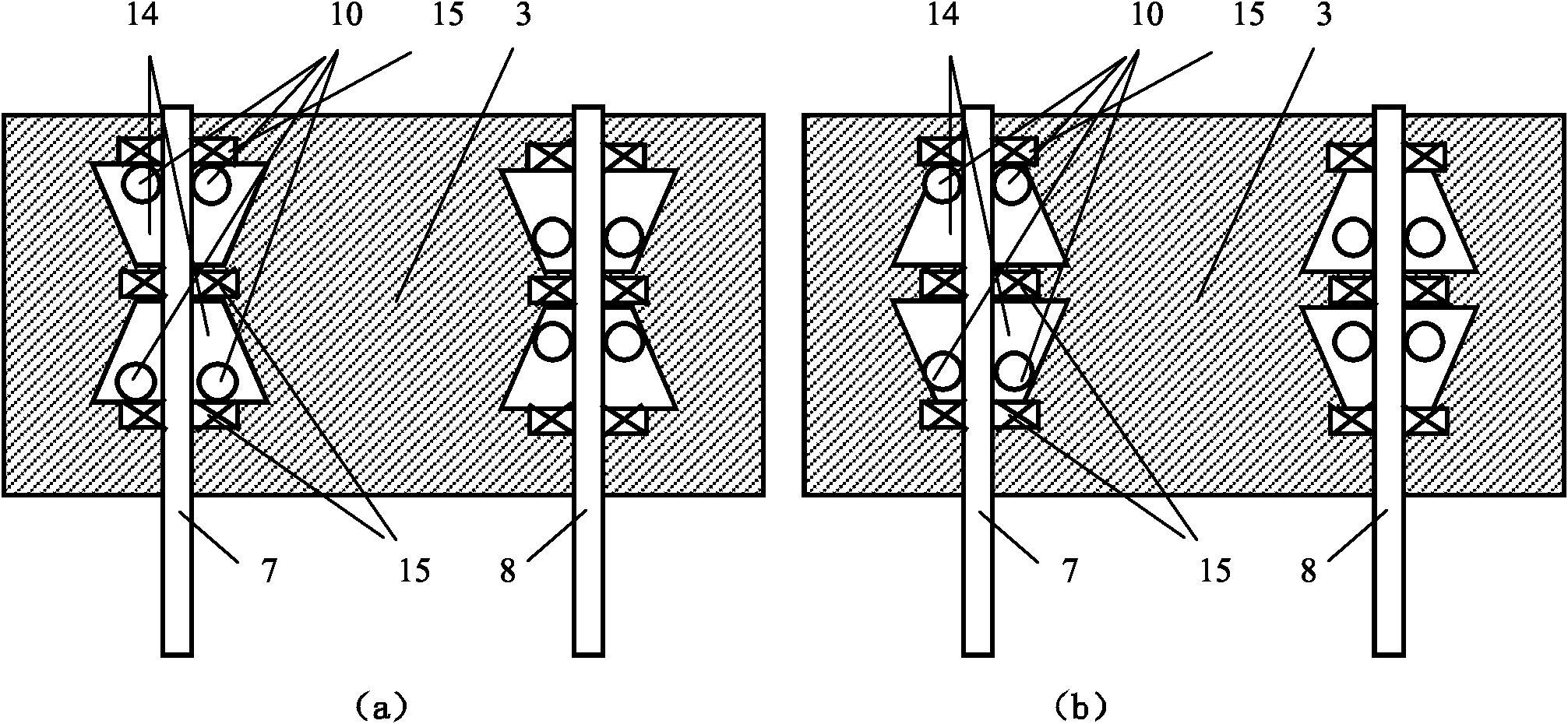

[0063] Such as Figure 7-Figure 9 As shown, this embodiment includes: a support frame 1 , one or three driving mechanisms 2 arranged in the support frame 1 and a vibration platform 3 connected thereto.

[0064] The drive mechanism 2 is composed of a driver 4 and a driver output rod 5 fixedly connected thereto. The top end of the driver output rod 5 is hinged to the drive platform 4 .

[0065] Described hinge all adopts spherical hinge or cross hinge 19 to realize.

[0066] When working, the three-degree-of-freedom movement realized is: three precision-driven vibration tables at three fulcrums act simultaneously to move up and down the vibration platform 4; Swing form; thereby realizing a reciprocating linear motion, and two swinging motions, such a three-degree-of-freedom motion platform.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com