Device for filling cigarette tubes

A smoke pipe and tobacco technology, applied in the field of smoke pipe devices, can solve problems such as production troubles and bobbin damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

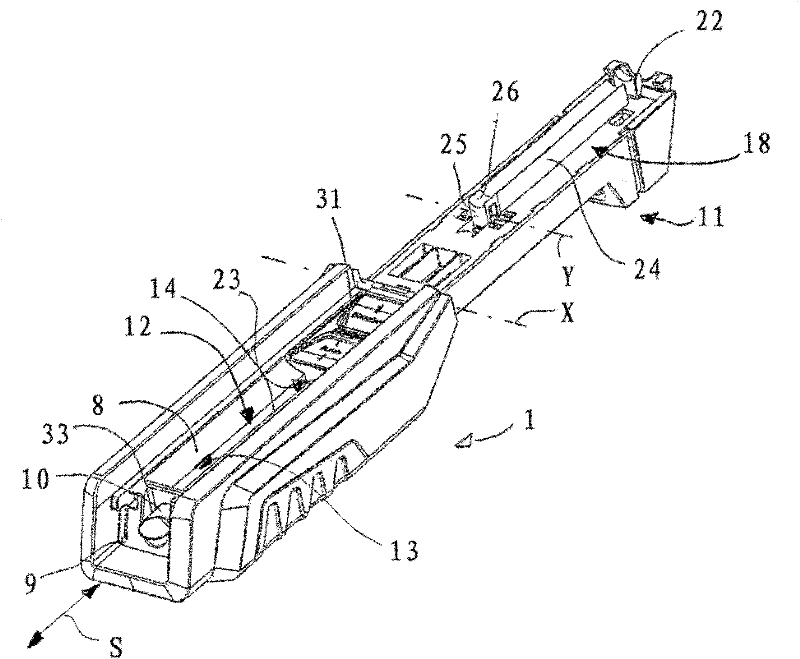

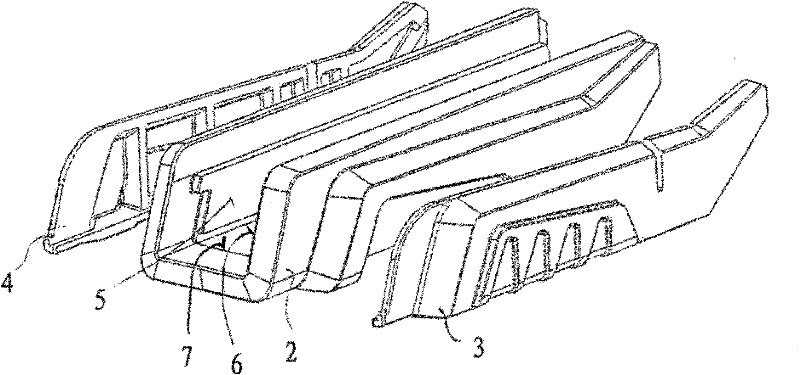

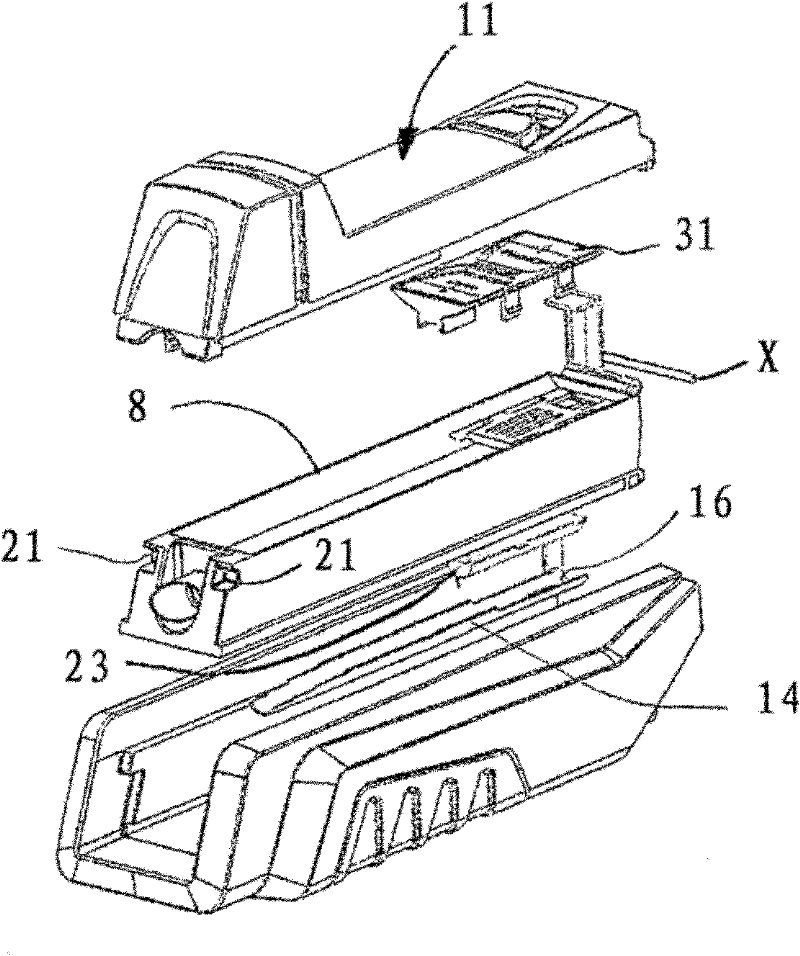

[0028] The device, indicated as a whole at 100 in the figures, comprises a housing 1 with a base 2 and with lateral grips 3 , 4 inserted into the base and locked. Both the base 2 and the lateral grips 3, 4 are made of plastic. The grips 3, 4 may be made of a softer material than the base 2 and of another color in order to improve the visual appearance of the device and make it more comfortable to handle.

[0029] In the base 2 of the housing 1 , a slide 8 is guided linearly in the direction of movement S between its inner side walls 5 , 6 and its bottom wall 7 . In order to fix the slider 8 perpendicularly to the bottom wall 7 , the slider 8 comprises on both sides protrusions 9 forming extensions of the bottom surface, which engage in complementary recesses in the side walls 5 , 6 .

[0030] Shown on the left side in the accompanying drawings, the end described in front of the following, on the slider 8 is provided with a set of openings 10, the outer diameter of which is ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com