Three-station operating mechanism and switch cabinet

An operating mechanism and three-station technology, which is applied in the direction of electric switches, electrical components, circuits, etc., can solve the problem that the three-station operating mechanism cannot realize the complete interlock function, and the three-station operating mechanism and circuit breaker operation The mechanism cannot realize the complete interlocking function and other problems, and achieve the effect of compact structure, reliable use and good safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

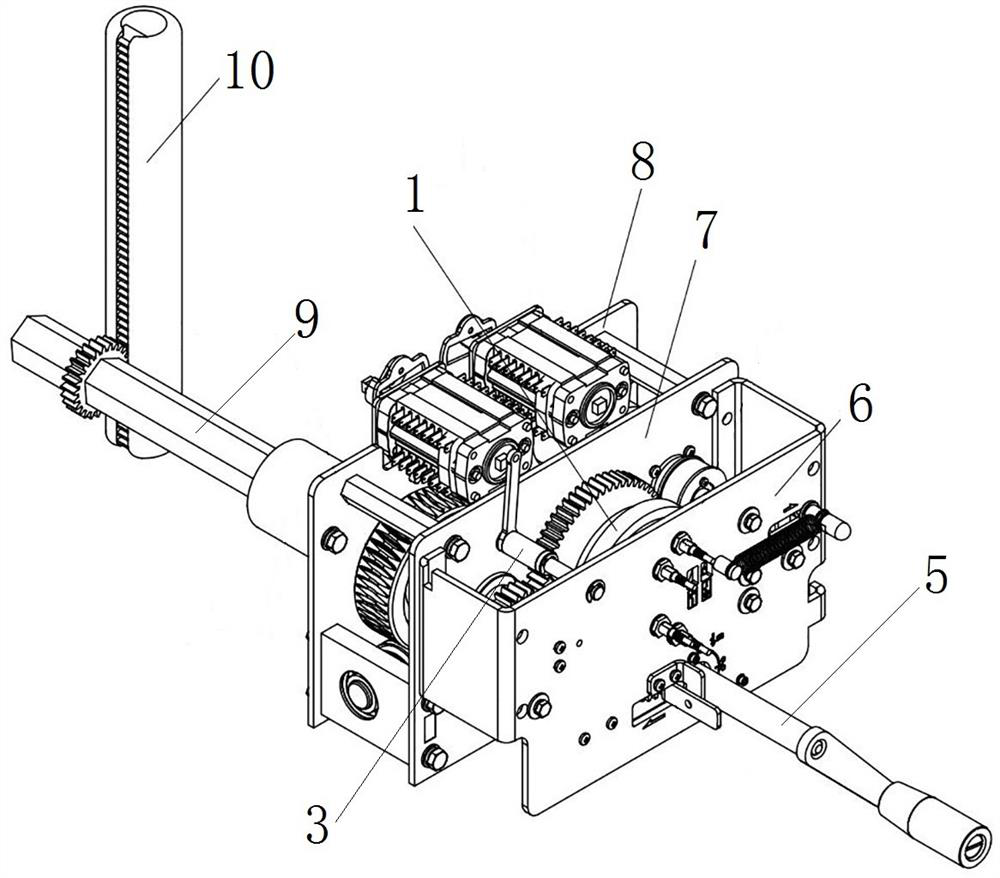

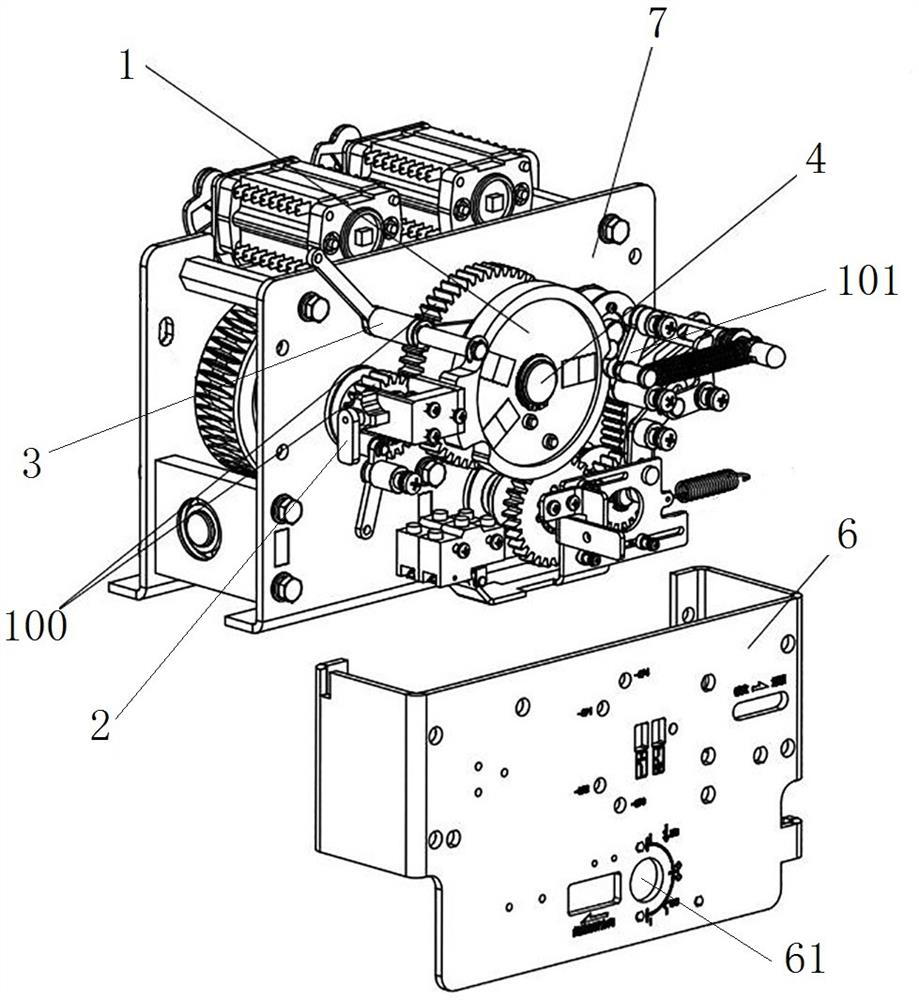

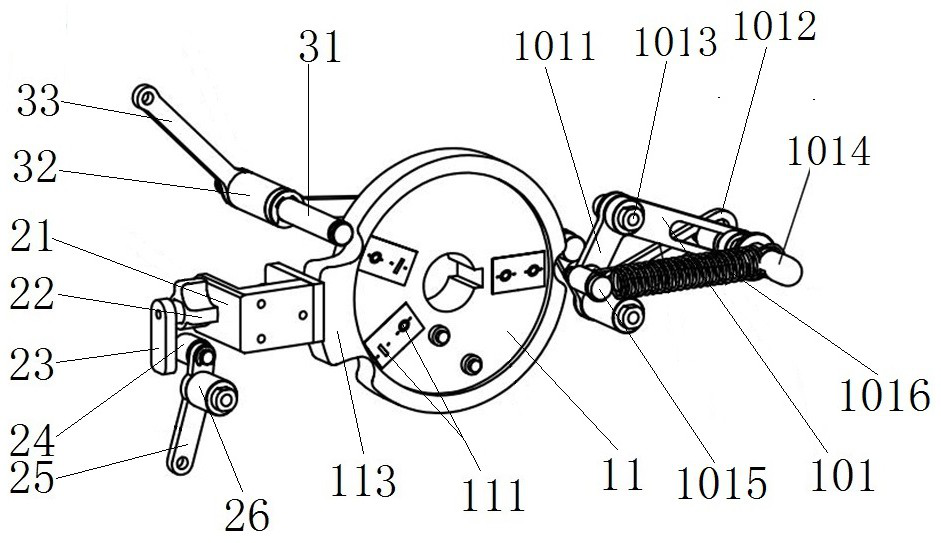

[0070] Such as figure 1 with figure 2 As shown, the three-position operating mechanism includes a mounting frame and a transmission assembly installed on the mounting frame. The mounting frame includes a panel 6, a front mounting plate 7 and a rear mounting plate 8 arranged in sequence. The transmission assembly has an input end and an output end. The input end is used for operating torque input, the output end includes an output shaft 9, and the output shaft 9 is used to drive the moving contact 10 of the three-position switch to operate. An operating hole 61 is provided on the panel 6 for inserting the operating handle 5 into the input end during manual operation.

[0071] The drive shaft 4 is also installed on the mounting bracket, and the drive shaft 4 is connected to the transmission assembly in a transmission manner. Under the action of the input torque, the transmission assembly drives the drive shaft 4 to rotate. In this embodiment, the drive shaft 4 and the transmis...

Embodiment 2

[0095] The difference between this embodiment and Embodiment 1 is that the second mating surface in Embodiment 1 is formed by the groove wall surface of the cam groove, while in this embodiment, the locking dial includes a front disk, a middle disk and a For the rear end cam, the third mating surface is arranged on the front plate, the first mating surface is arranged on the middle disk, and the second mating surface is directly formed by the outer peripheral surface of the rear end cam. At this time, the reverse interlocking mechanism also includes a Spring to maintain the position of the second lock.

Embodiment 3

[0097] The difference between this embodiment and Embodiment 1 is that the positive interlocking groove in Embodiment 1 is provided on the outer peripheral surface of the interlocking turntable and the notch is radially outward, while in this embodiment, the positive interlocking groove It is arranged on the disk surface of the interlocking turntable, the forward interlocking groove is an annular groove, and the annular groove has a concave part, and the concave part is used to form a first locking section for the first locking part to snap in. Correspondingly, the first locking The component is located on the disk side of the interlocking turntable, and the groove wall surface of the annular positive interlocking groove is used to form the first mating surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com