Three-dimensional adjustment measuring platform capable of automatically loading large-diameter optical lens

An optical lens, three-dimensional adjustment technology, applied in the direction of optical instrument testing, measuring device, machine/structural component testing, etc., can solve the problems of low adjustment accuracy, low detection efficiency, poor stability, etc., to ensure work flexibility and efficiency. Running water detection, saving the effect of manual lifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific structure of the present invention will be described in further detail below in conjunction with the accompanying drawings.

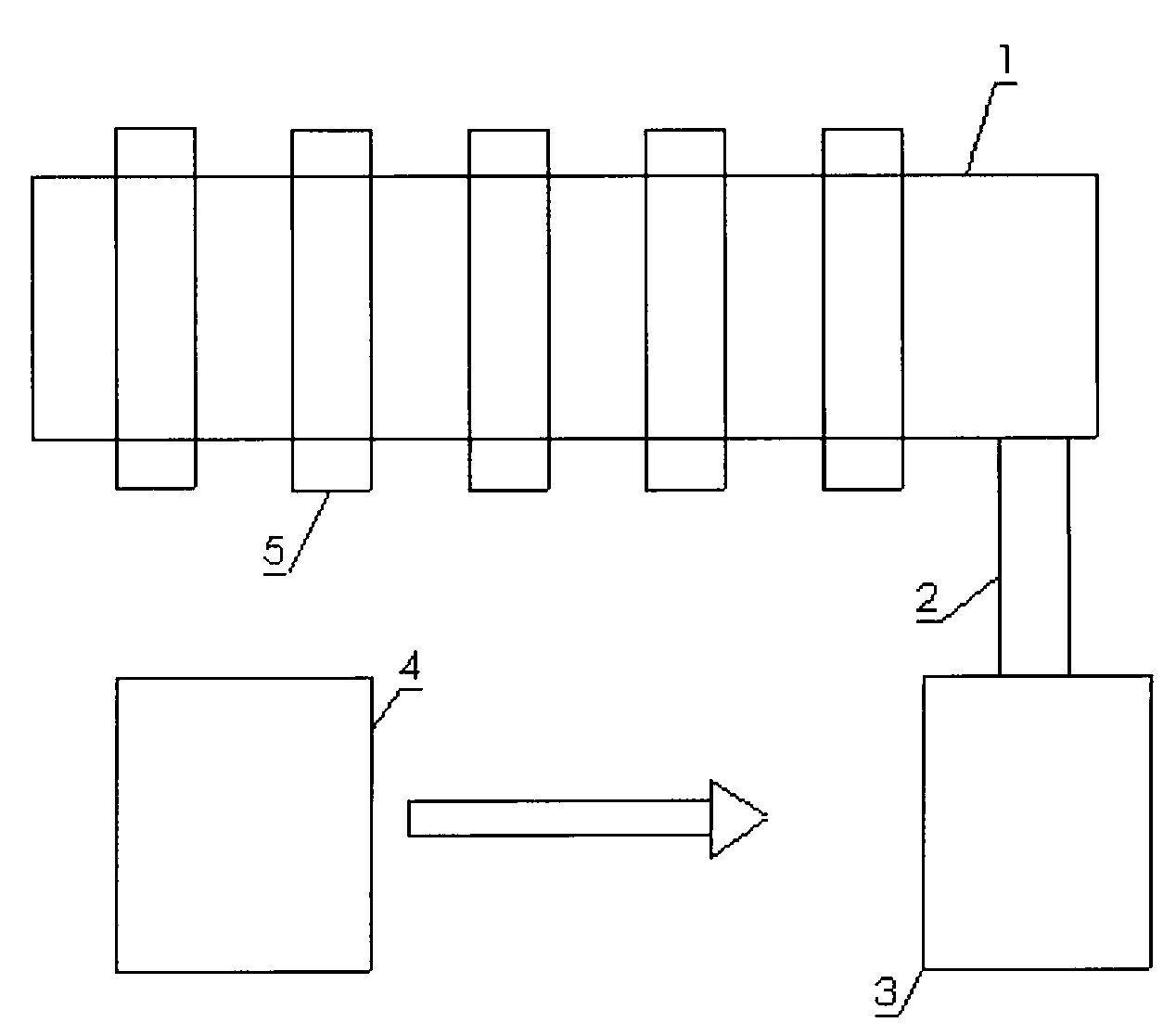

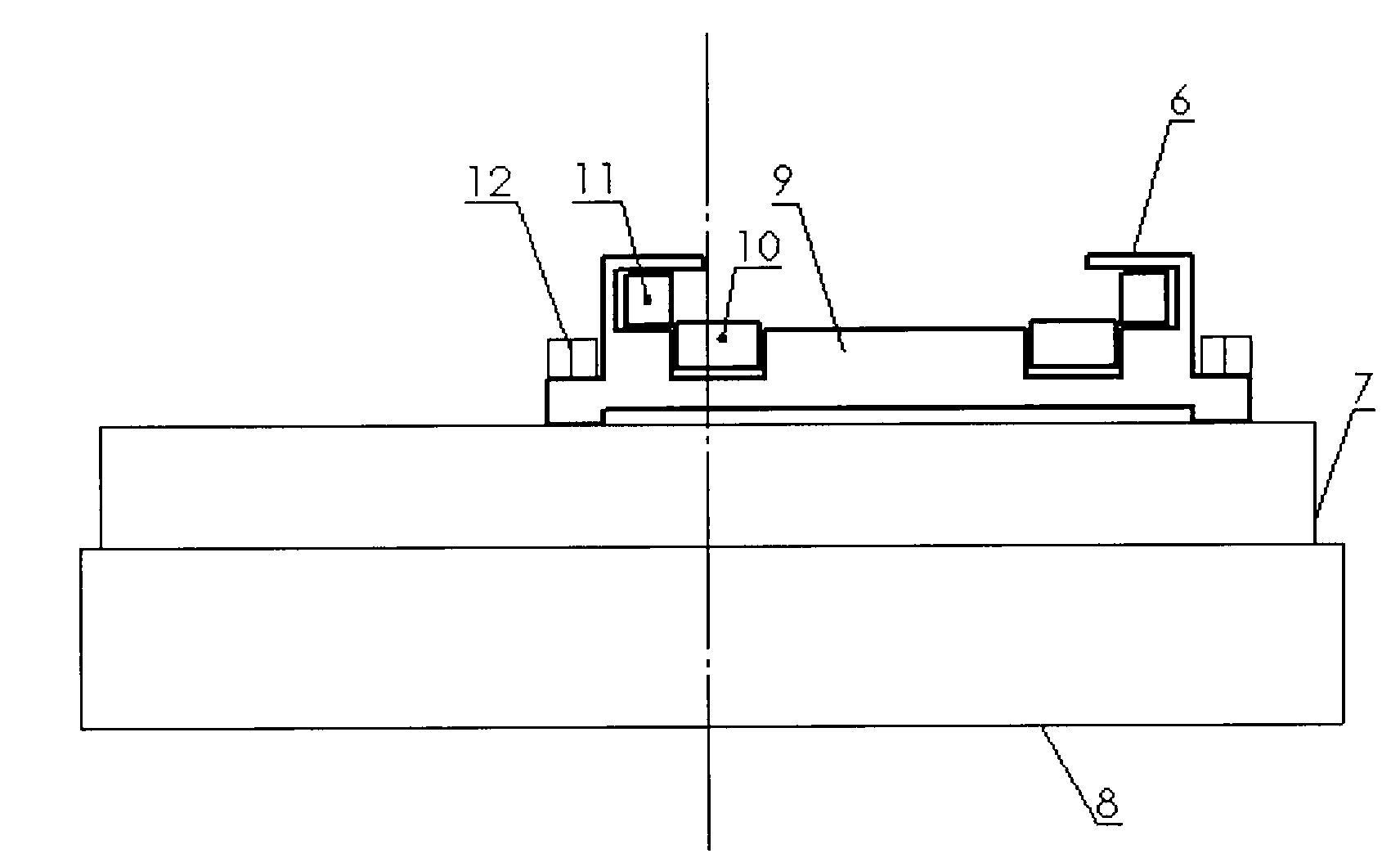

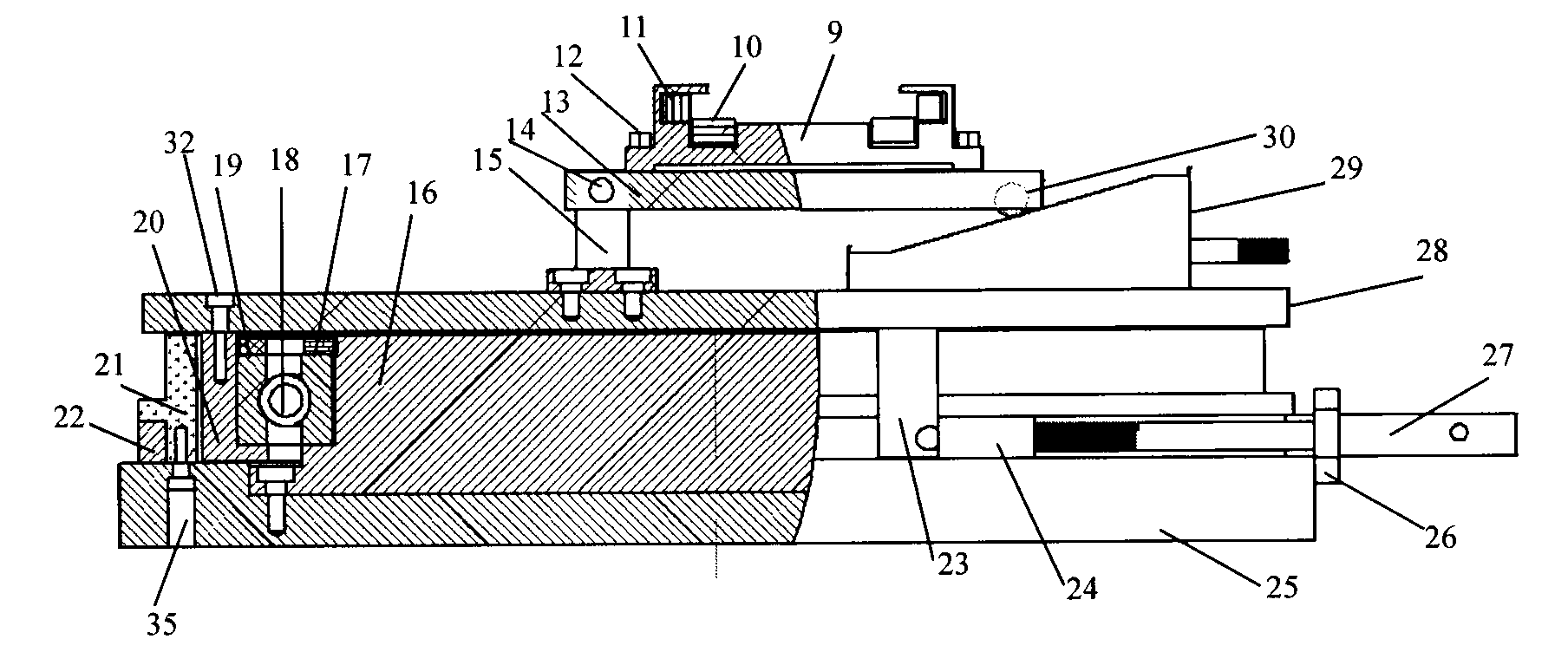

[0016] see figure 1 According to the three-dimensional adjustment measuring platform that can automatically load large-caliber optical lenses made according to the present invention, it is mainly composed of a multi-station balance table 1, a transmission mechanism 2, and a three-dimensional adjustment mechanism 3, and a plurality of The large-diameter optical lens workpiece holder 5 and the three-dimensional adjustment mechanism 3 are connected to the multi-station balance table 1 through the transmission mechanism 2 , and the measured surface of the optical element of the three-dimensional adjustment mechanism 3 faces the interferometer 4 . see figure 2 , image 3 , the three-dimensional adjustment mechanism 3 is composed of a transmission table assembly 6, a pitch adjustment assembly 7, and a rotation table assembly 8 that can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com