Humid heat simulation test accelerating method for photovoltaic module

A photovoltaic module, damp heat test technology, applied in the direction of weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., can solve the problems that cannot meet the needs of new material evaluation, and achieve a reasonable test method that is conducive to application and promotion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

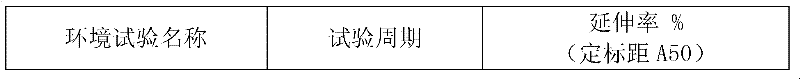

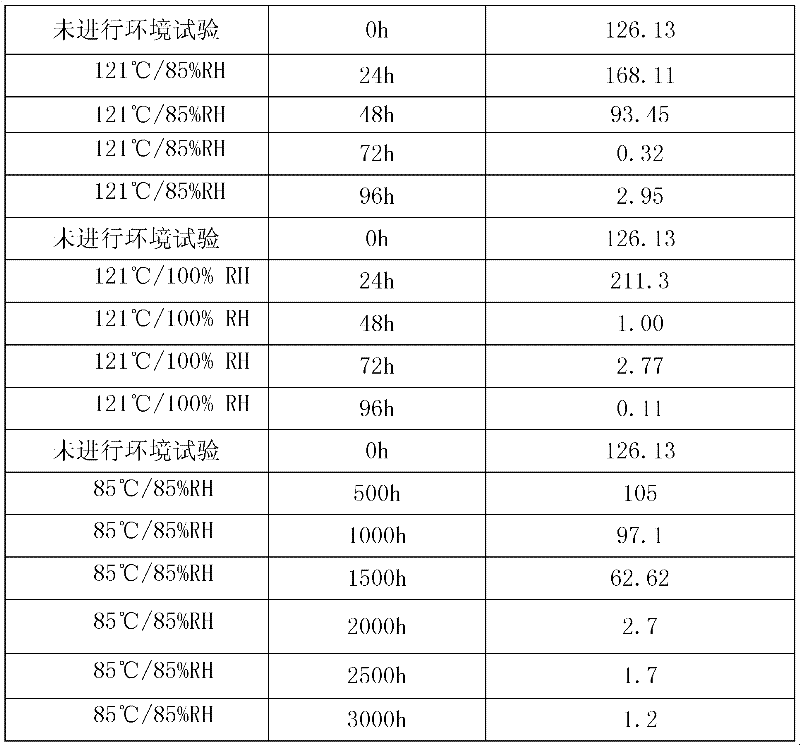

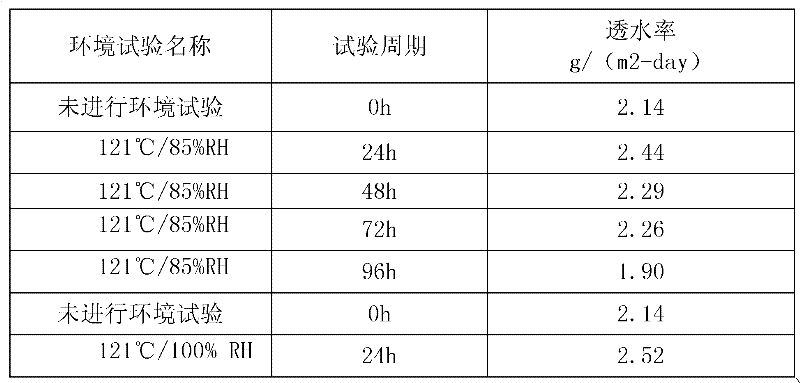

[0012] Embodiment 1: The accelerated test method of simulated damp heat test of photovoltaic modules, selecting material samples for photovoltaic modules, test environment 1: 121°C / 100%RH; test environment 2: 121°C / 85%RH; test environment 3: 85°C / 85% RH; 2 pieces of samples were tested in each test environment, and the appearance, breakdown voltage, water permeability, yellowing index, tensile force, and elongation were tested before and after the experiment.

[0013] Table 2 shows the changes in the appearance of the samples after the experiment in the three test environments.

[0014] Table 2:

[0015] Environmental test name

Test Cycle

Visual inspection results

No environmental test

0h

OK

121℃ / 85%RH

24h

curly

121℃ / 85%RH

48h

curly

121℃ / 85%RH

72h

curly

121℃ / 85%RH

96h

become brittle

No environmental test

0h

OK

121℃ / 100%RH

24h

curly

121℃ / 100%R...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com