Selective high-efficiency wall and floor tile turning device

A high-efficiency technology for wall and floor tiles, applied in the field of ceramic wall and floor tile production equipment, can solve the problems of complex structure, high failure rate, and high turnover error rate, and achieve the effect of accurate turnover action and meeting the needs of large-volume production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with specific examples.

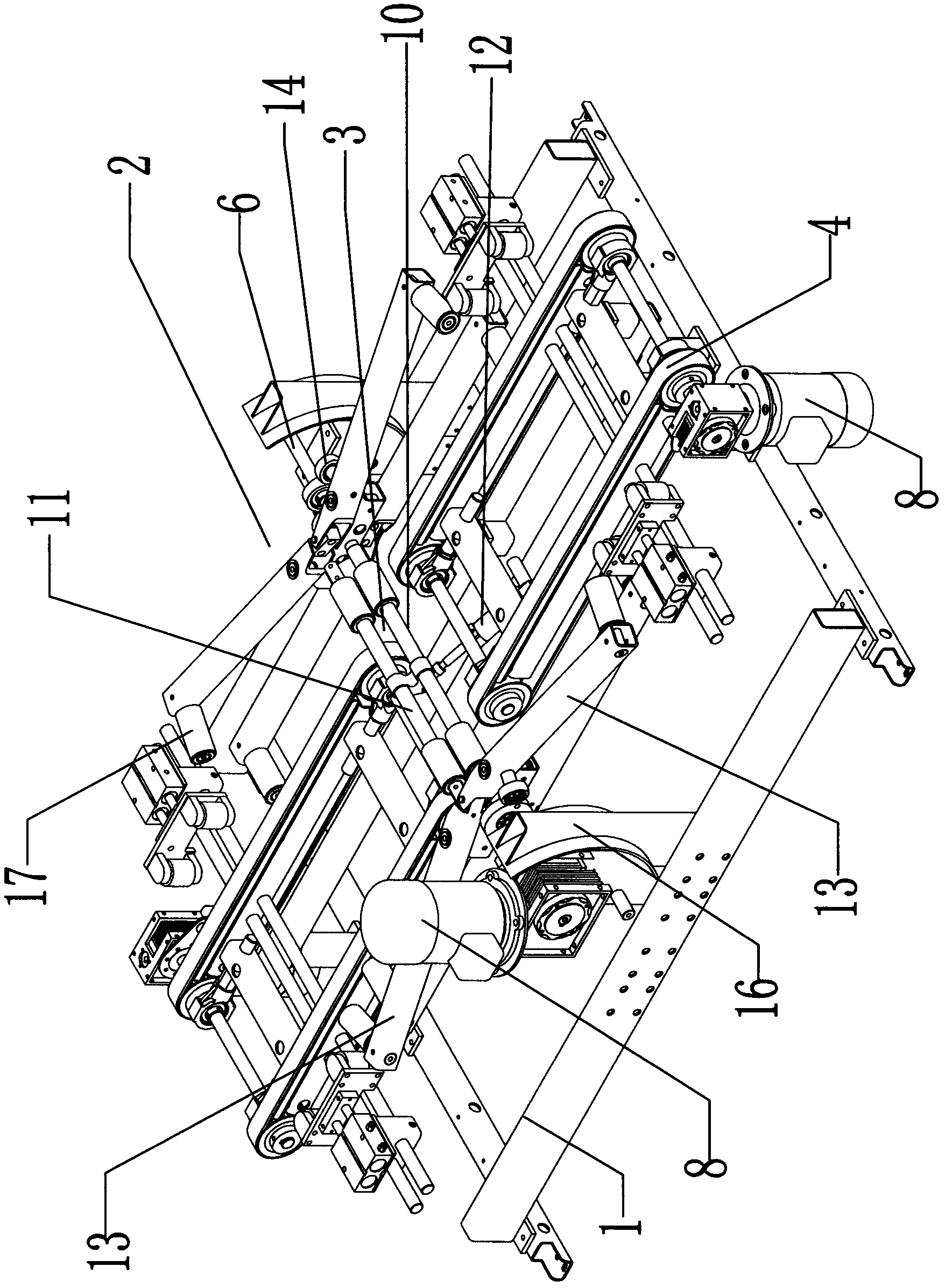

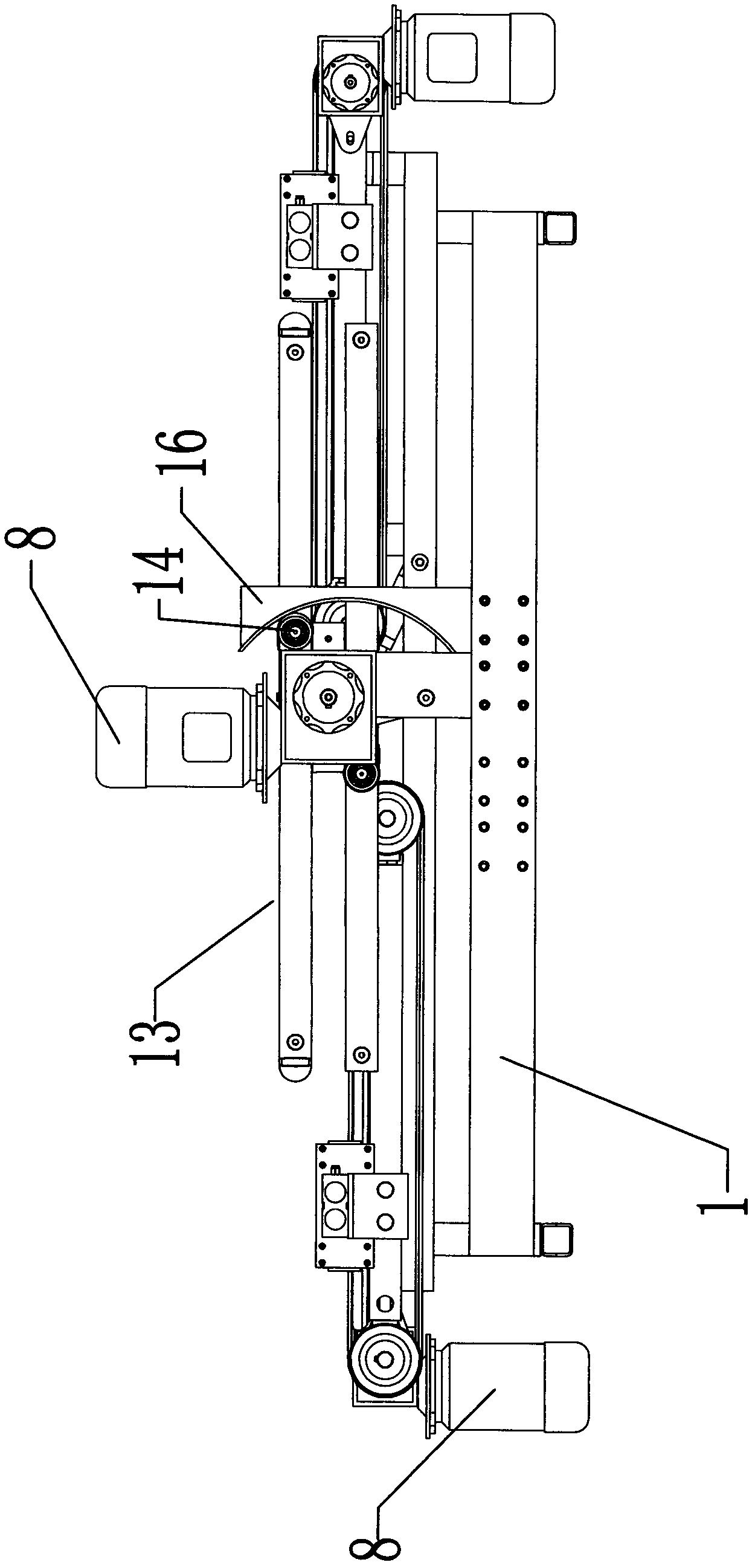

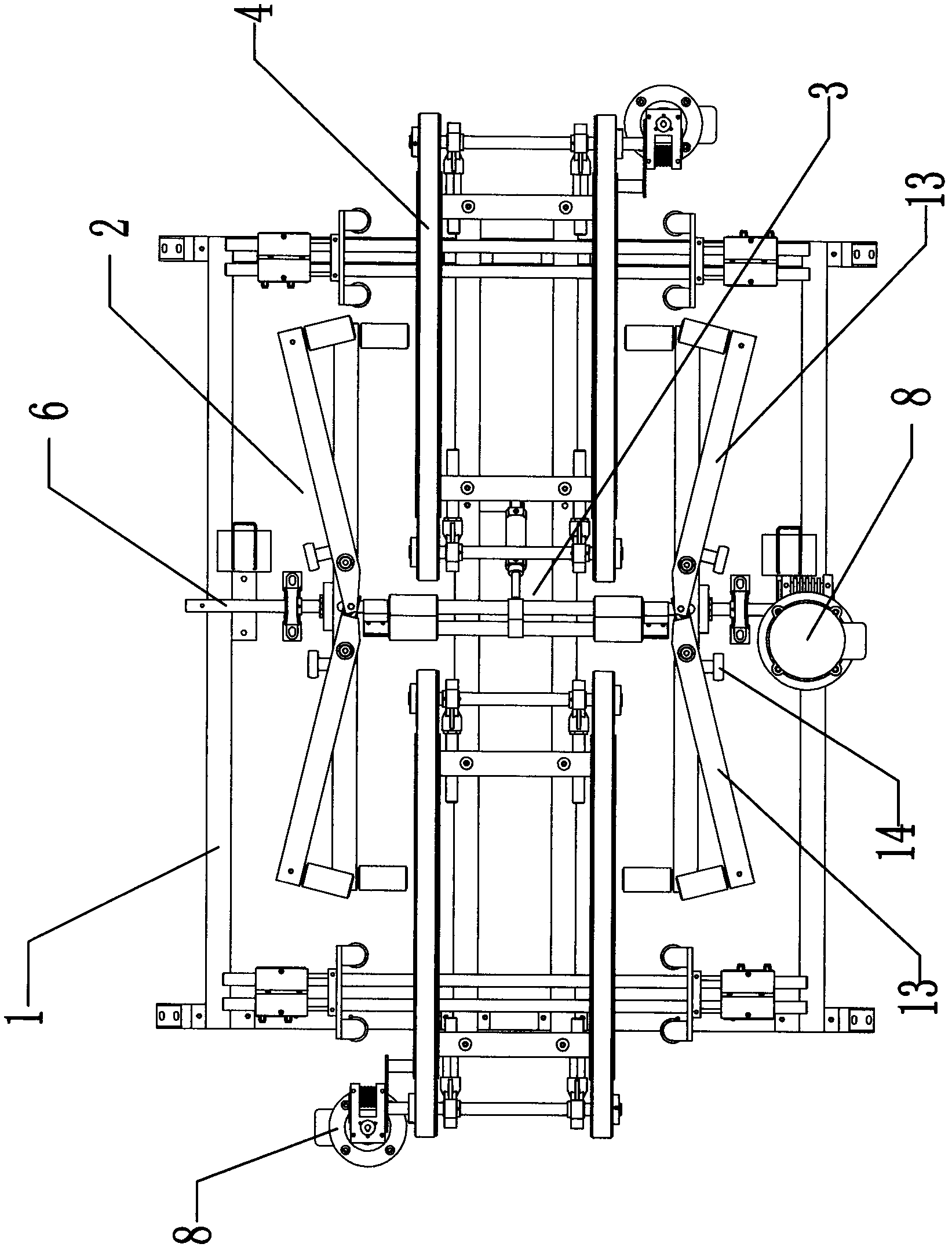

[0015] According to attached figure 1 to attach Figure 6 As shown, the preferred embodiment of the present invention includes a frame 1, an overturning frame assembly 2, a supporting brick assembly 3 and two groups of belt conveying wire racks 4 connected upstream and downstream; wherein, the overturning frame assembly 2 consists of The left and right turning arms 5, the turning main shaft 6, the bearing 7 and the gear motor 8 are composed; the two sets of belt conveyor racks 4 connected upstream and downstream are installed on the frame 1 and there is a gap at the joint; the turning frame assembly 2 passes through its bearing 7 Installed on the frame 1, and its turning spindle 6 passes through the gap between the two sets of belt conveying wire racks 4; the bracket assembly 3 is installed on the frame 1, and is located in the middle of the gap between the two sets of belt c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com