Preparation method of porous alumina membrane with two layers communicated with each other

A technology of porous alumina and alumina film, applied in the field of material science, can solve problems such as the destruction of alumina film, and achieve the effects of easy control of reaction, simplified preparation process and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Under the condition of ice-water bath (~0°C), immerse 99.999% high-purity aluminum foil in a mixture of perchloric acid and ethanol with a volume ratio of 1:4 for electrochemical polishing, with a current of 200mA and a polishing time of 1 min;

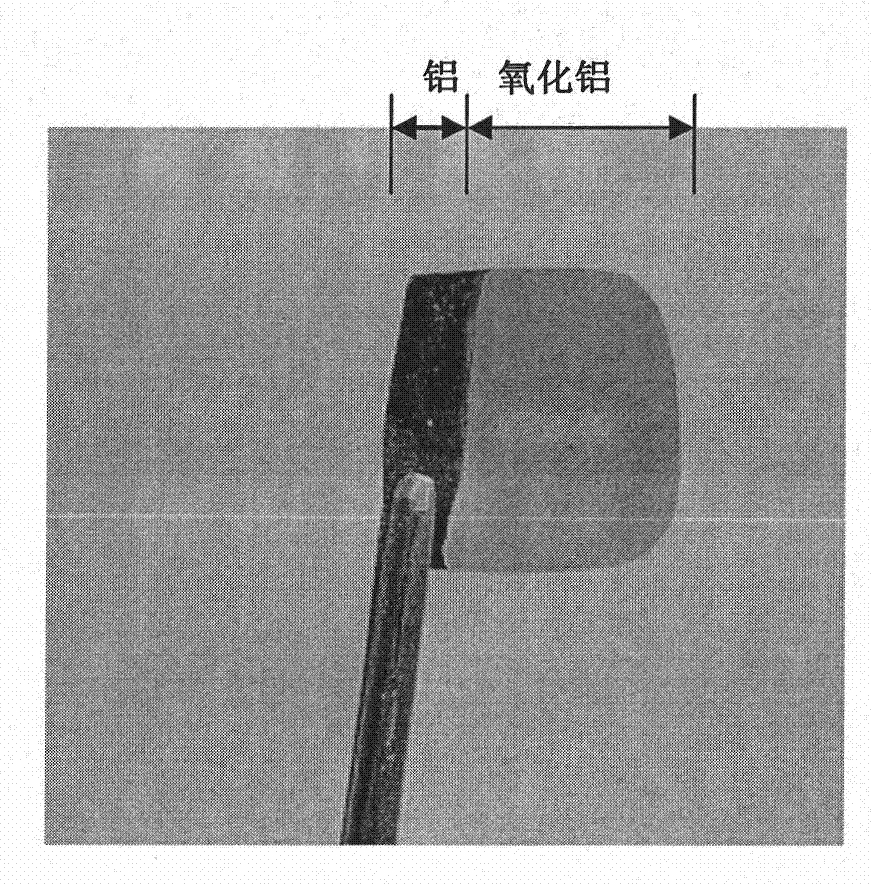

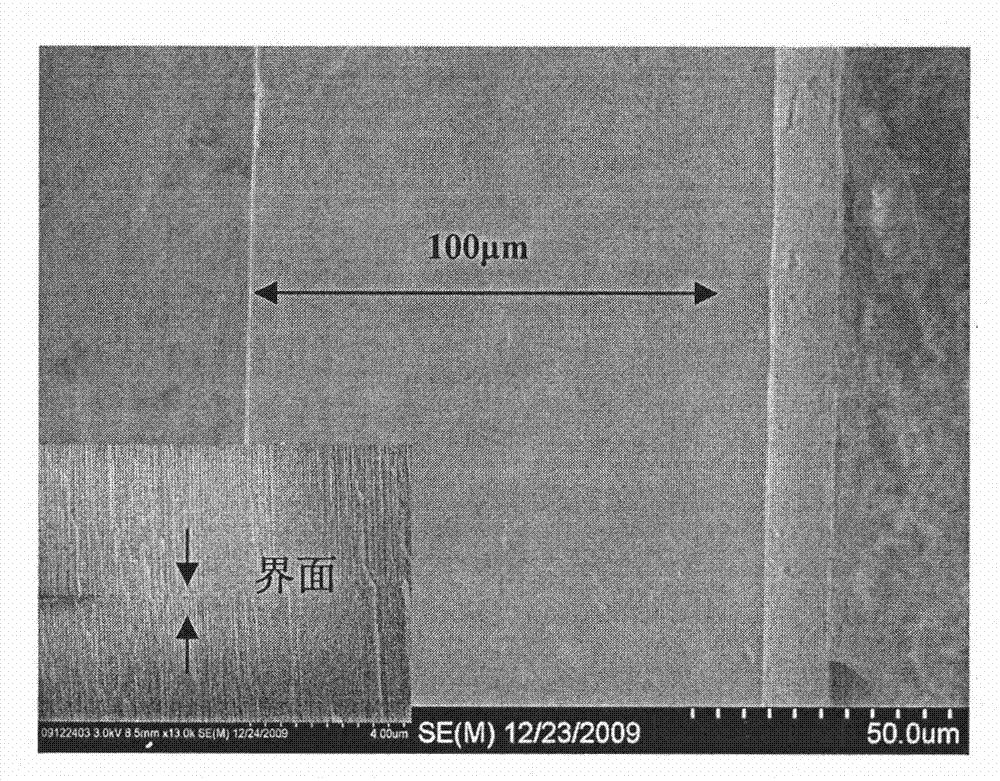

[0020] (2) Under stirring, pre-oxidize the polished high-purity aluminum foil in 0.3mol / L oxalic acid electrolyte at a voltage of 10-20V and a current of 7mA for 0.5h, then fine-tune the aluminum foil (oxidized film) position, lift up the aluminum foil so that the top of the aluminum foil is slightly exposed to the electrolyte surface by 1 mm, and continue to oxidize for 3 hours under the conditions of a voltage of 30V and a current of 5-8mA;

[0021] (3) The aluminum foil obtained in step (2) is heated in 0.6mol / L H at a temperature of 50°C 3 PO 4 and 0.18mol / L H 2 CrO 4 Immerse in the mixed solution mixed in equal volume for 1 hour to remove the oxide film on the surface of the aluminum foil;

...

Embodiment 2

[0026] (1) Under the condition of ice-water bath (~0°C), immerse 99.999% high-purity aluminum foil in a mixture of perchloric acid and ethanol with a volume ratio of 1:4 for electrochemical polishing, with a current of 200mA and a polishing time of 1 min;

[0027] (2) Under stirring, pre-oxidize the polished high-purity aluminum foil in 0.3mol / L oxalic acid electrolyte at a voltage of 10-20V and a current of 5mA for 1h, then fine-tune the position of the aluminum foil (oxidation film) , lift the aluminum foil up, so that the top of the aluminum foil is slightly exposed to the electrolyte surface by 2mm, and continue to operate at a voltage of 40V and a current of 10-15mA

[0028] Oxidation under the condition of 1.5h;

[0029] (3) The aluminum foil obtained in step (2) is heated in 0.6mol / L H at a temperature of 50°C 3 PO 4 and

[0030] 0.18mol / L H 2 CrO 4 Immerse in the mixed solution mixed in equal volume for 1 hour to remove the oxide film on...

Embodiment 3

[0036] (1) Under the condition of ice-water bath (~0℃), immerse 99.999% high-purity aluminum foil in a mixture of perchloric acid and ethanol with a volume ratio of 1:4 for electrochemical polishing, with a current of 150mA and a polishing time of 2 min;

[0037] (2) Under stirring, pre-oxidize the polished high-purity aluminum foil in 0.3mol / L oxalic acid electrolyte for 0.5h at a voltage of 10-20V and a current of 3.5mA, then fine-tune the aluminum foil (oxidation film) Lift the aluminum foil upwards, so that the top of the aluminum foil is slightly exposed to the electrolyte surface by 3 mm, and continue to oxidize for 2 hours under the conditions of voltage 35V and current 8-10mA;

[0038] (3) The aluminum foil obtained in step (2) is heated in 0.6mol / L H at a temperature of 50°C 3 PO 4 and 0.18mol / L H 2 CrO 4 Immerse in the mixed solution mixed in equal volume for 1 hour to remove the oxide film on the surface of the aluminum foil;

[0039] (4...

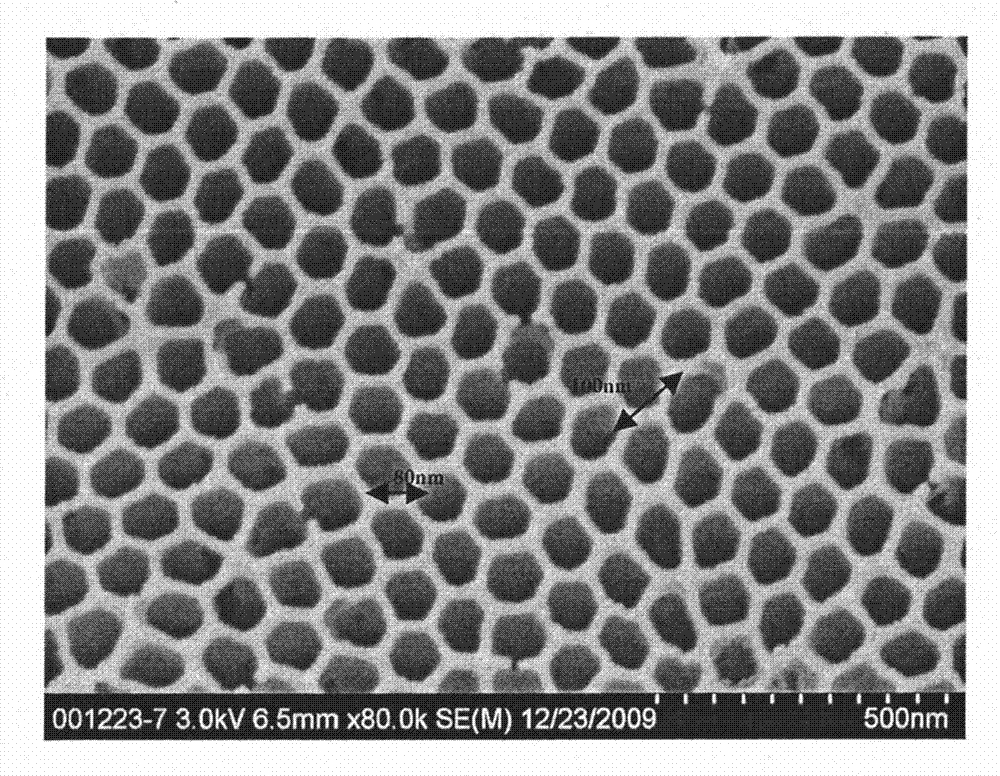

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com