Submerged arc welding current pulse control circuit

A current pulse and control circuit technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., to achieve the effect of increasing the melting depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings of the description.

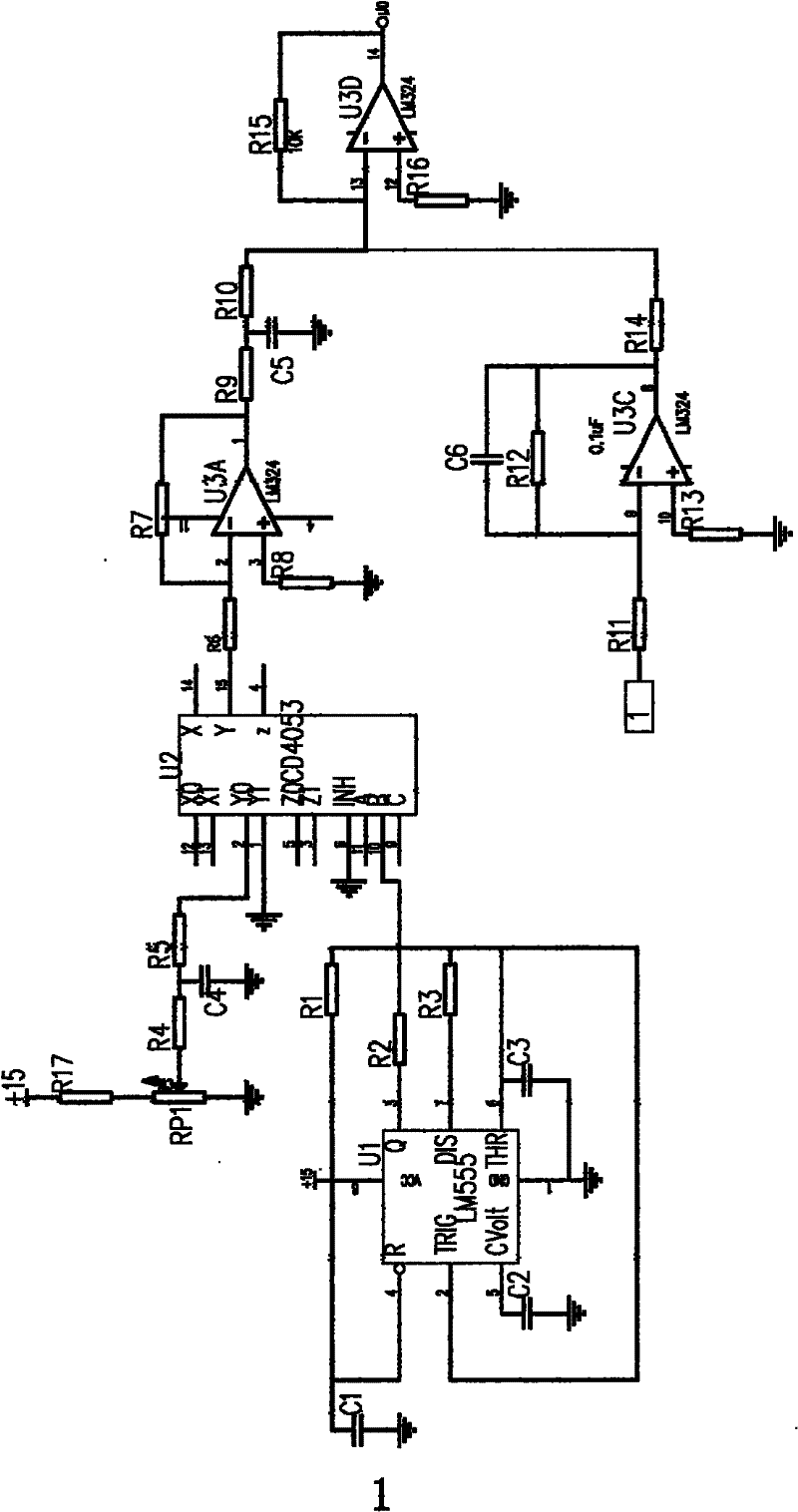

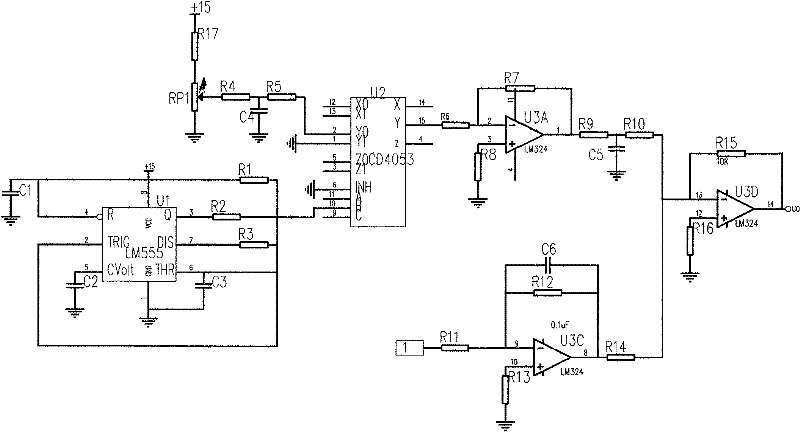

[0012] Such as figure 1 As shown, a submerged arc welding current pulse control circuit includes a multivibrator circuit, an analog switch circuit U2, operational amplifiers U3A, U3D, U3C, resistors R4, R5, R17, RP1, and a capacitor C4. The models of the operational amplifiers U3A, U3B, and U3C are all LM324. The multivibrator circuit includes a time base circuit U1, resistors R2, R3, and capacitors C3, C2. The model of the time base circuit U1 is LM555, and its Q terminal is connected to the B pin of CD4053 through a resistor R2. The model of the analog switch circuit U2 is CD4053, the Y pin of the analog switch circuit U2 is connected to the "-" terminal of the operational amplifier U3A, and the "+" terminal of the operational amplifier U3A is connected to the ground through a resistor R8. After resistors R17 and RP1 are connected in series, one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com