Three dimensions vibration measuring apparatus and method

A technology of three-dimensional space and vibration measurement, which is applied in the direction of measuring device, vibration measurement, vibration measurement in solids, etc., can solve the problems of high cost, low measurement accuracy, and complex structure of vibration measurement device, and achieve low cost and simple processing Immediate, easy-to-implement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that the following only describes the features of the present invention that are different from the prior art, and the technical features that can be found in the prior art will not be repeated here.

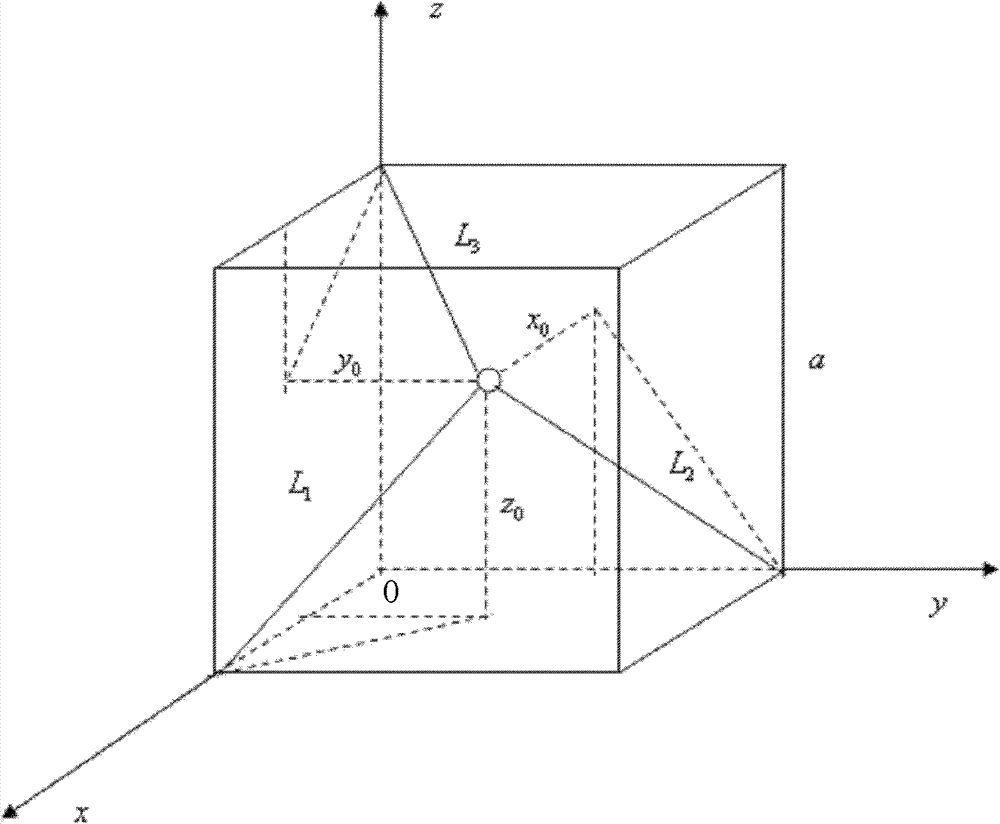

[0029] For ease of understanding, the basic principle of the present invention is briefly described first. The three-dimensional space vibration measuring device of the present invention uses three pull-wire displacement sensors to measure the vibration displacement signals of the measured object in the corresponding three directions, and then uses the spatial coordinate transformation method to convert the signals of the three pull-wire displacement sensors into three Vibration displacements in two mutually perpendicular degrees of freedom.

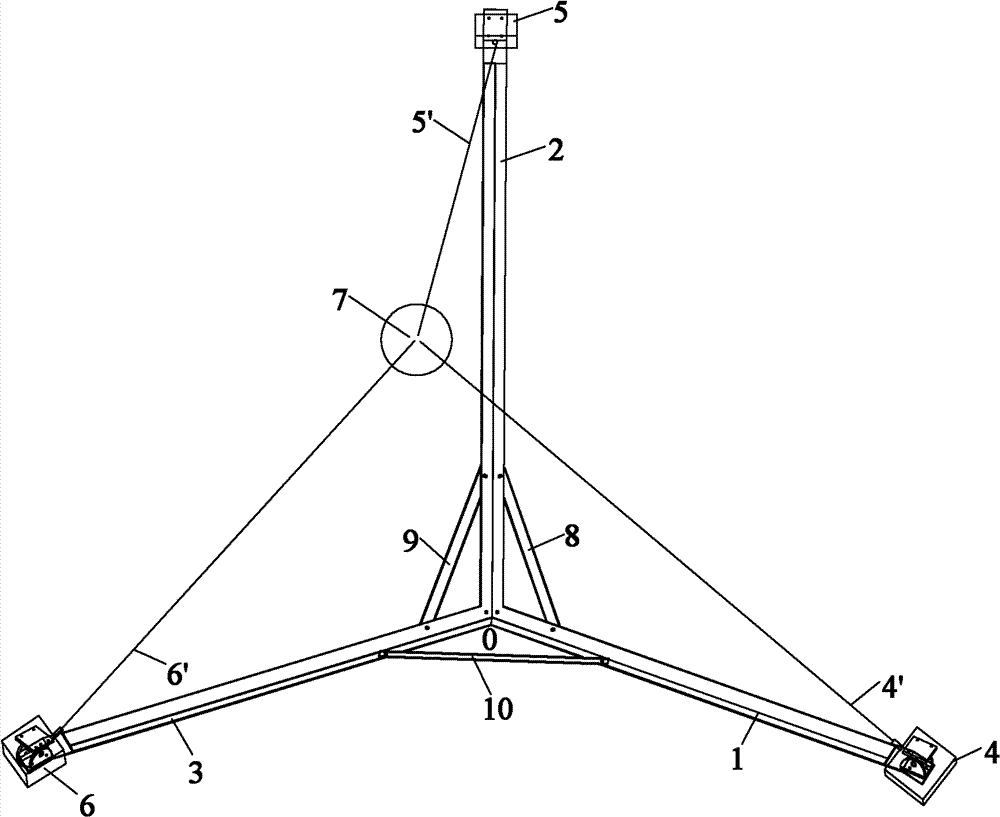

[0030] First refer to figure 2 , introduce a preferred embodiment of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com