Defrosting method of microwave oven

A technology for microwave ovens and food, applied in the field of microwave ovens, can solve problems such as over-thawing of objects to be thawed, corresponding wrong judgments, uneven temperature distribution, etc., and achieve the effects of improving system stability, reducing control errors, and avoiding over-thawing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

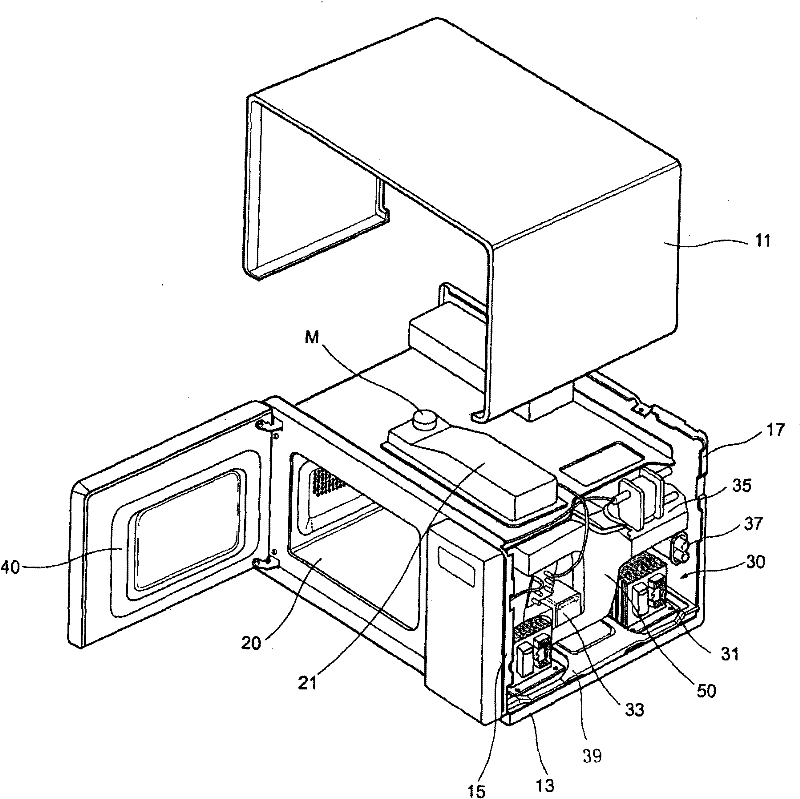

[0023] The present invention is described in detail below with reference to accompanying drawing and embodiment:

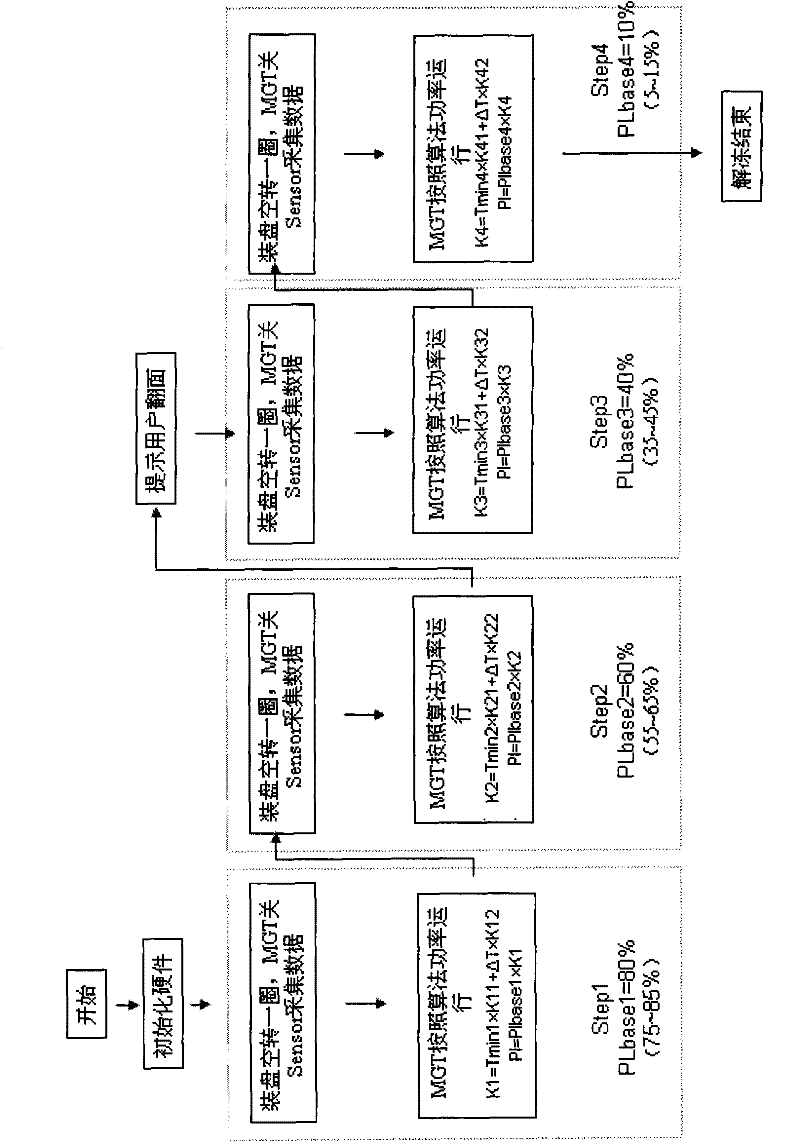

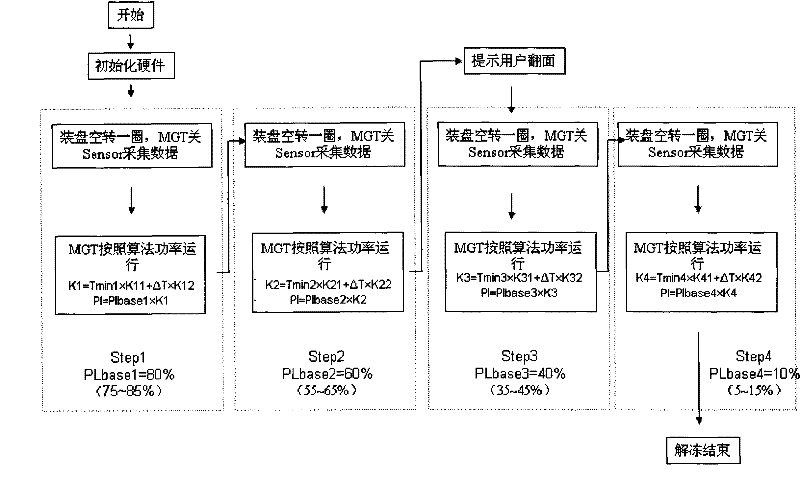

[0024] figure 2 It is a flowchart of the thawing method of the microwave oven of this invention.

[0025] Such as figure 2 As shown, the thawing method of the microwave oven of the present invention, wherein the sensor probe of the microwave oven uses multiple sampling points to measure the temperature of the food at the same time, and each sampling point is arranged on a diameter of the food tray. At the beginning of thawing, the temperature sensor, controller and other hardware are initialized; the sensor starts to work, and measures the temperature of each point on the diameter of the tray through multiple sampling points at the same time, and judges the temperature of the object falling on the object according to the temperature difference between each point. The number of sampling points, the measurement results of the sampling points that do not cover or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com