System and method for directly measuring total helium mass flow rate of primary loop of high-temperature gas cooled reactor

A high-temperature gas-cooled reactor and mass flow technology, applied in indirect mass flow meters, mass flow measurement devices, etc., can solve the problems of increasing helium fan power requirements and large pressure loss, achieving no additional pressure loss, good reliability, Reproduce the effect with high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings and examples. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0039] An embodiment of the present invention provides a system for directly measuring the total mass flow rate of helium in the primary circuit of a high-temperature gas-cooled reactor, which includes:

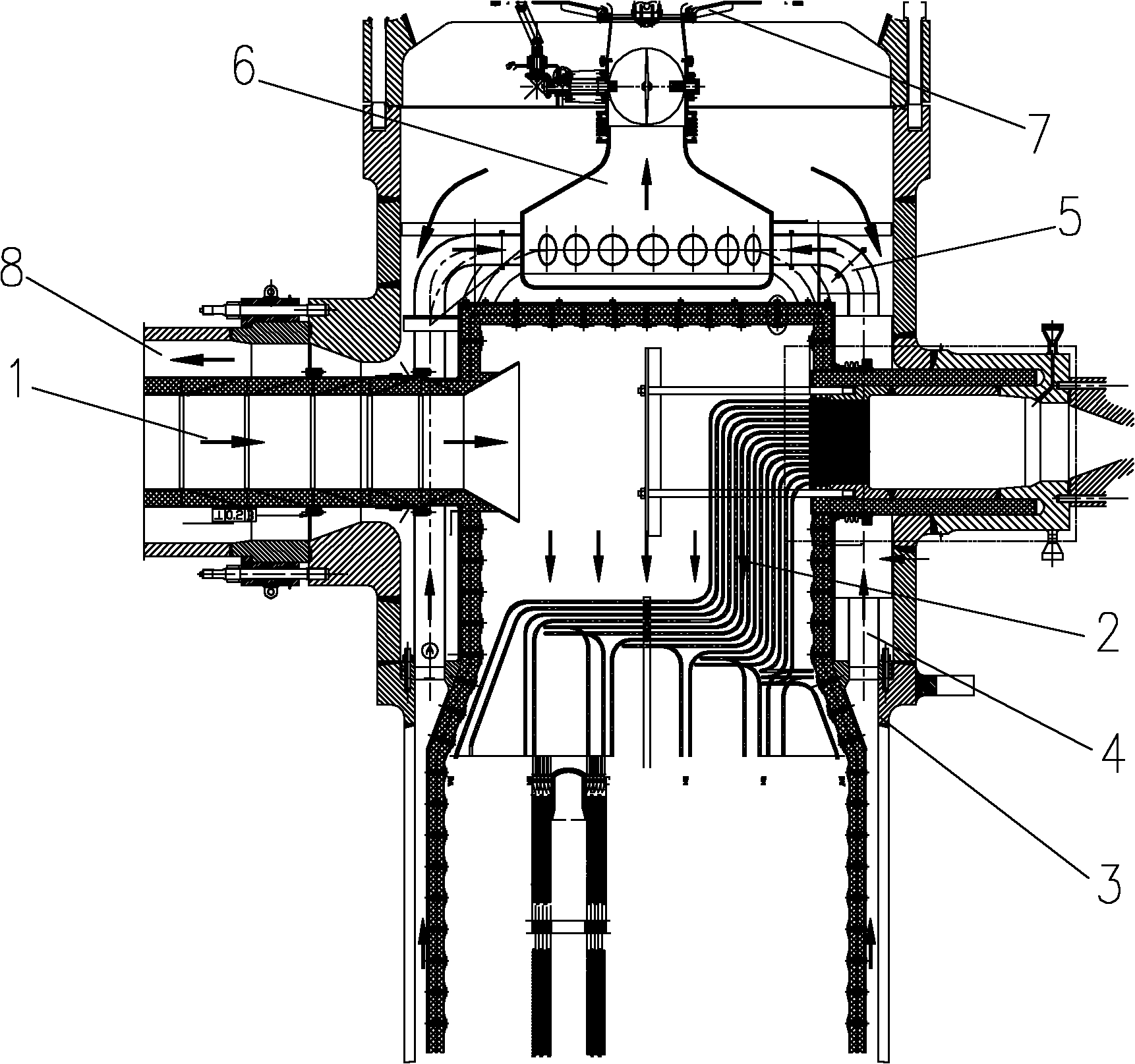

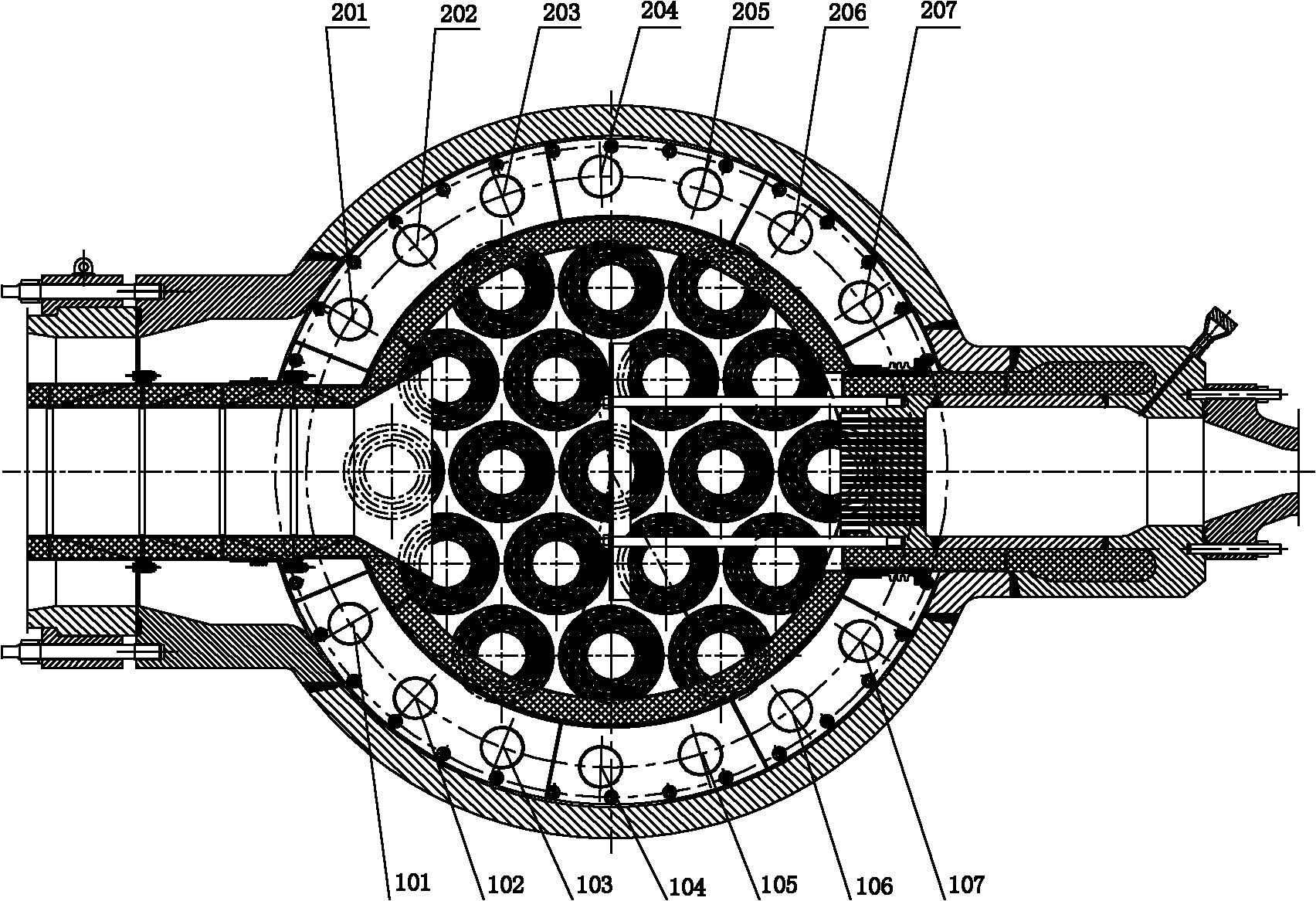

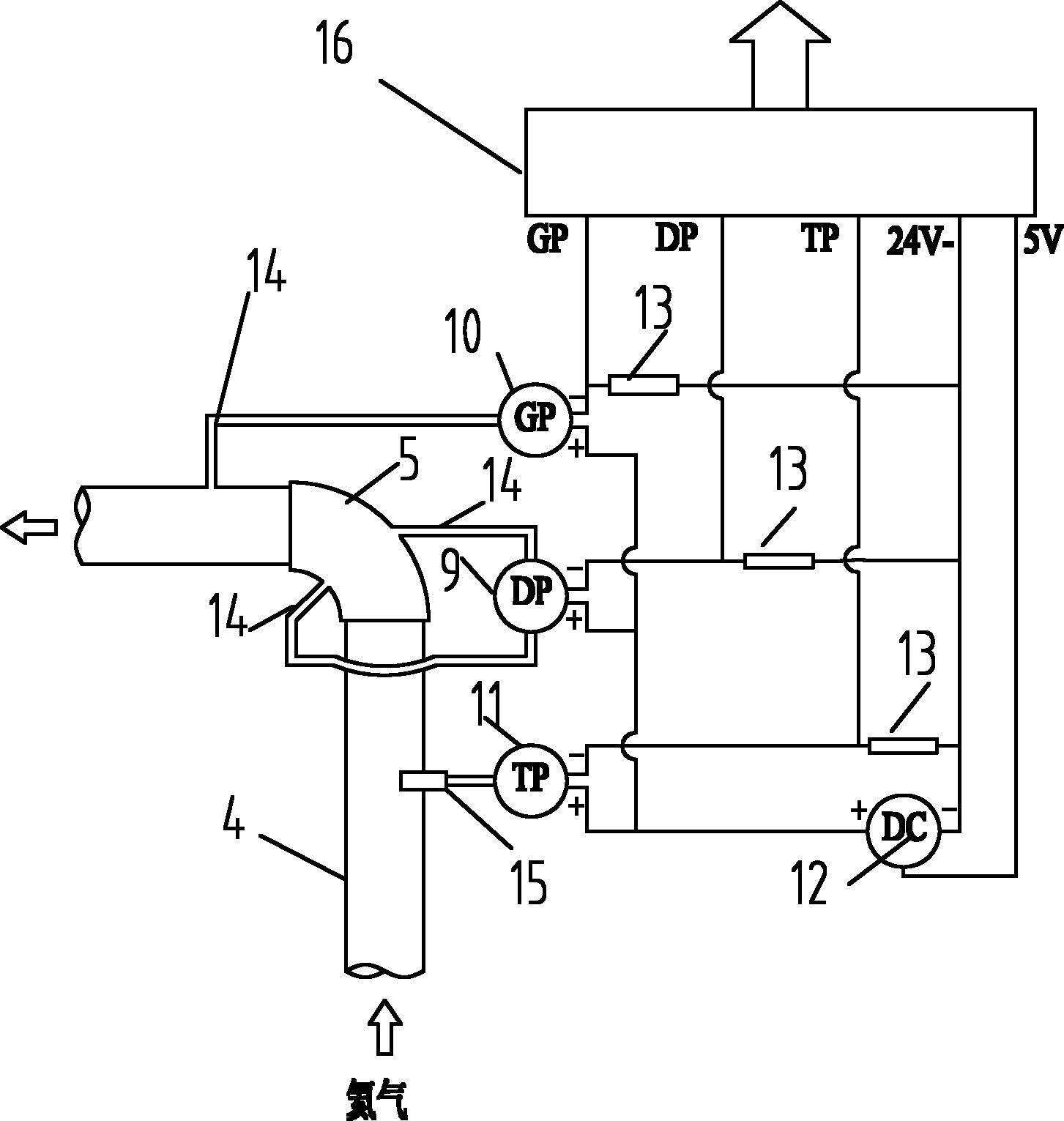

[0040] Such as figure 2 , 3As shown, a precision-machined integral elbow flow sensor 5 is installed at the positions of the cold helium riser tubes 102, 106, 202, and 206 of the steam generator of the high-temperature gas-cooled reactor; a capacitive differential pressure transmitter 9 (1152DP) receives the differential pressure signal inside and outside the elbow sensor 5 through the pressure induction pipe 14 inside and outside the elbow flow sensor 5; the capacitive pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com