Rear work roll unit of profile bending machine

A bending machine and work roll technology, applied in the field of profile bending manufacturing, can solve problems such as unfavorable installation and transportation, large external dimensions, etc., and achieve the effect of eliminating movement interference and improving transmission efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

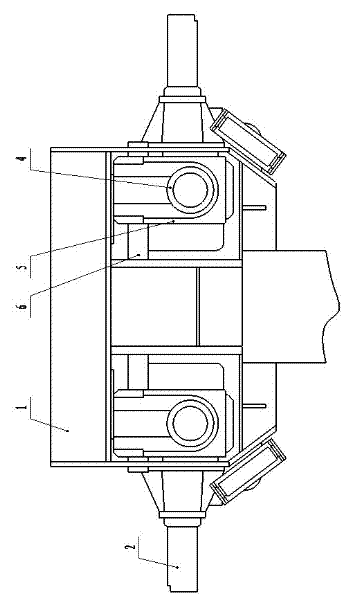

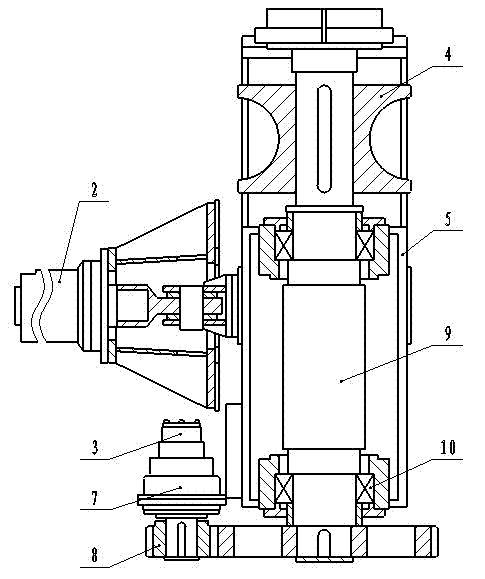

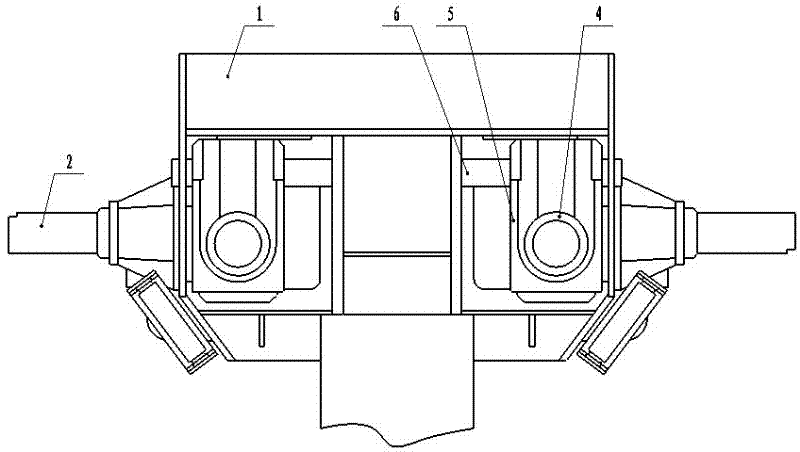

[0012] Such as figure 1 , figure 2 As shown, the rear work roll device of the profile bending machine of the present invention includes: a rear roll frame body 1, a rear roll moving cylinder 2, a rear roll transmission device 3, a rear roll 4, a rear roll moving frame 5 and a guide rail 6, two structures The same rear roller moving frame 5 is arranged on both sides of the rear roller frame body 1 through the guide rail 6. A rear roller moving cylinder 2 is provided on one side of each rear roller moving frame 5, and each rear roller moving frame 5 is provided with The rear roller 4 is provided with a rear roller transmission device 3 below the rear roller 4.

[0013] The rear roller transmission device 3 includes: a hydraulic motor 7, a gear 8, a transmission shaft 9 and a bearing 10. The hydraulic motor 7 is arranged at the bottom of the rear roller moving frame 5, and the hydraulic motor 7 is connected to the transmission shaft 9 through two meshing gears 8 For connection, on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com