Full-hydraulic four-roller numerical control rolling machine

A fully hydraulic, plate bending machine technology, applied in the field of fully hydraulic four-roll CNC plate bending machine, can solve the problems of deviation of rolling and pressure gap, poor connection stability, and the synchronization of four rollers cannot be well controlled, and achieves advanced The effect of accurate material direction and angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

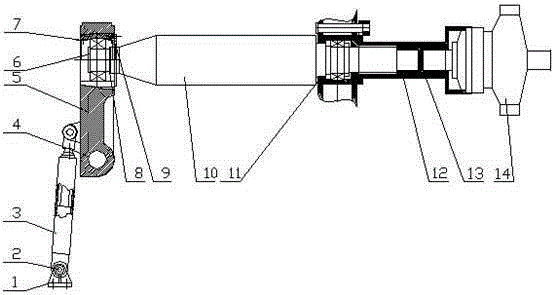

[0032] In order to enable those skilled in the art to better understand the technical solution of the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

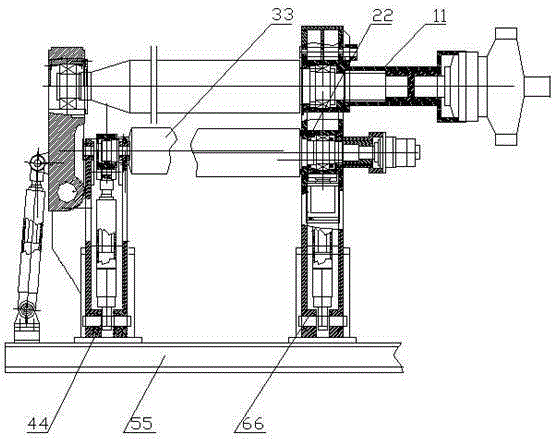

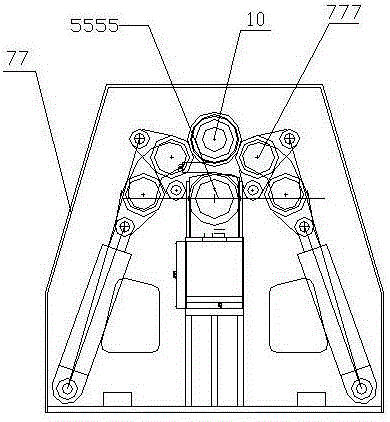

[0033] Refer to attached Figure 1-8 A full-hydraulic four-roller numerically controlled plate rolling machine shown includes a machine body 77, and a four-roller synchronous rolling mechanism, a side automatic loading mechanism, an unloading mechanism and an electrical system are arranged in the body 77, and the four-roller synchronous The crimping mechanism includes an upper roller device 11, a lower roller device 22, and left and right side roller devices 33, and the side automatic feeding mechanism is arranged on the side of the four-roller synchronous crimping mechanism; wherein,

[0034] Described upper roller device 11 comprises upper roller 10, and the diameter of upper roller is 380mm, is divided into free ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com