Multifunctional plate rolling machine

A plate bending machine and multi-functional technology, applied in the field of multi-function plate bending machines, can solve the problems of increasing procurement cost, single function, and can only perform plate rolling operations, and achieve the effect of reducing procurement cost and improving utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

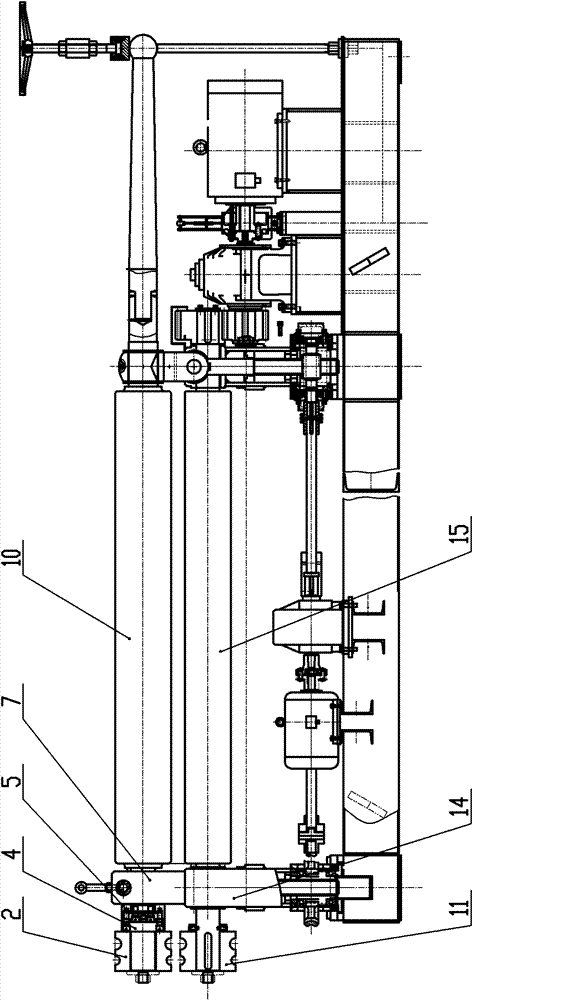

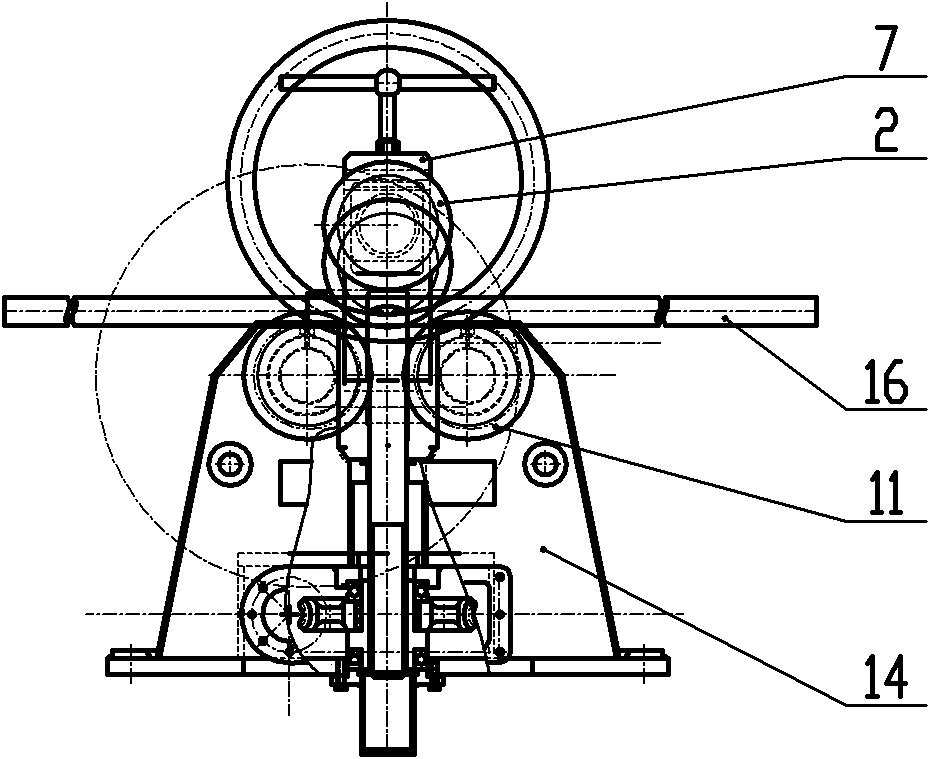

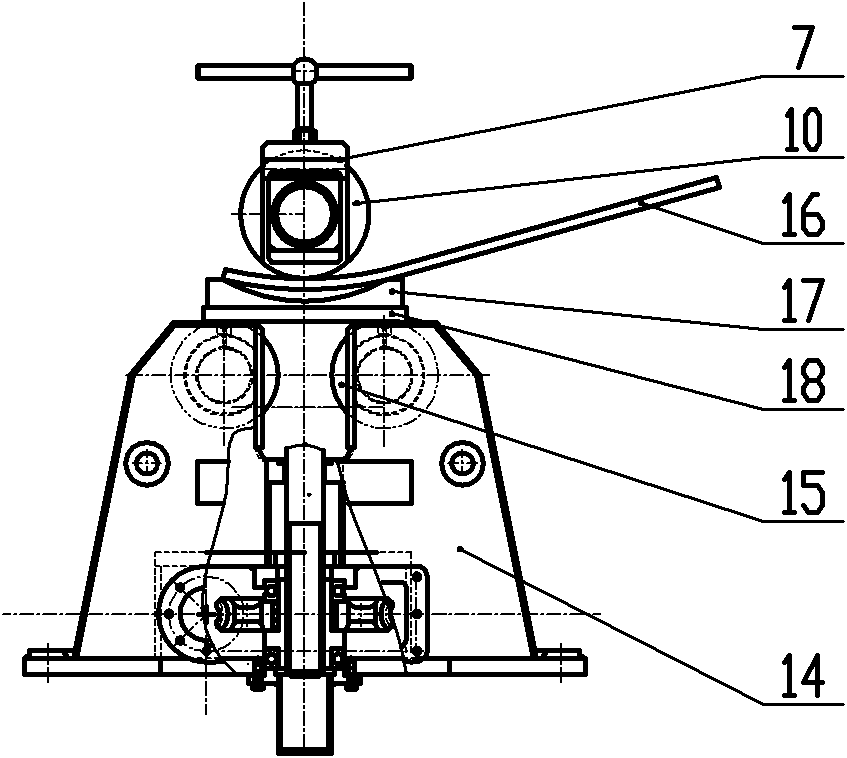

[0024] Figure 1~Figure 8 Among them, including baffle plate 1, upper die 2, upper die bushing 3, upper roll shaft extension joint 4, connecting plate 5, pin shaft 6, overturning seat 7, overturning bearing seat 8, bushing 9, upper roll 10 , lower mold 11, flat key 12, positioning retaining ring 13, lower roller seat 14, lower roller 15, workpiece 16, pre-bending mold 17, backing plate 18, small shaft extension 19, counterbore 20, boss 21, a word Groove 22, internally threaded hole 23, groove 24 etc.

[0025] Such as figure 1 As shown, the present invention is a multi-functional plate bending machine, which is reformed on the basis of the existing mechanical upward adjustment symmetrical three-roller plate bending machine, which includes an upper roll 10 and two lower rolls 15 .

[0026] The shaft extension of the discharge side of the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com