Symmetrical groove curve periodic roll

A technology of symmetrical holes and rolls, applied in metal rolling and other directions, can solve troubles, increase steel pipe production costs, waste of resources and other problems, and achieve the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

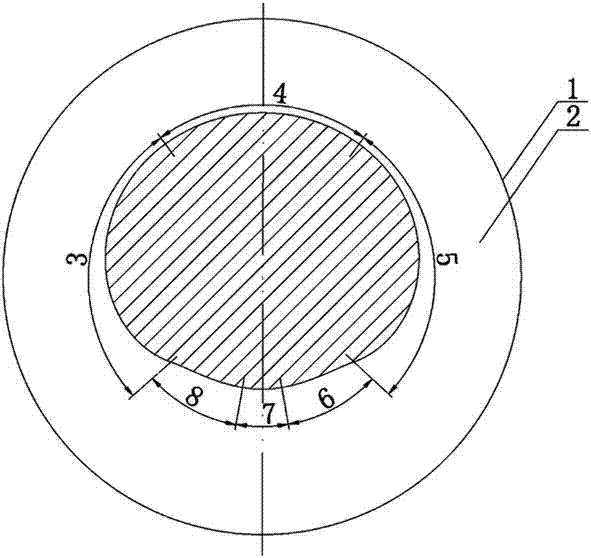

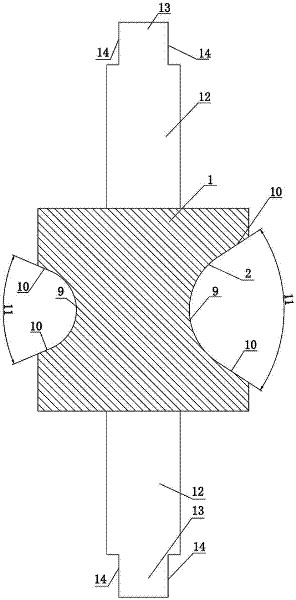

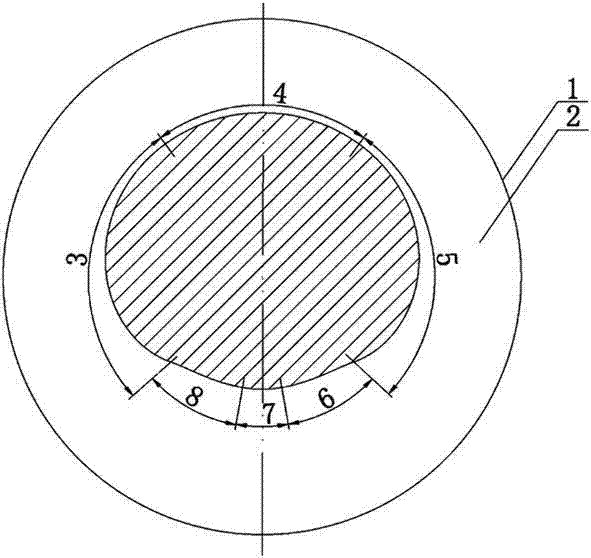

[0015] Example 1: Such as figure 1 , figure 2 , Symmetrical hole-shaped curve periodic roll, which includes roll 1, on the peripheral surface of roll 1 is machined with a hole pattern 2, the shape of the hole pattern 2 cut by a plane perpendicular to the axis of the roll 1 is a hole-shaped curve, the hole-shaped curve along The circumferential direction is divided into A section 3, B section 4, C section 5, D section 6, E section 7, and F section 8, and the direction of each section from the start point to the end point is clockwise, of which A section 3 is forging and rolling Section B, section 4 is the finishing rolling section, section C 5 is the final rolling section, section D 6, E section 7, and F section 8 are idle rolling sections. The curve is symmetrical about the axis of the passing roll 1 and the midpoint of the idle rolling section. The shape of the pass 2 cut by the plane of the axis of the roll 1 is composed of an arc 9 and two straight lines 10 tangent to the a...

Embodiment 2

[0018] Example 2: Such as figure 1 , figure 2 , Symmetrical hole-shaped curve periodic roll, which includes roll 1, on the peripheral surface of roll 1 is machined with a hole pattern 2, the shape of the hole pattern 2 cut by a plane perpendicular to the axis of the roll 1 is a hole-shaped curve, the hole-shaped curve along The circumferential direction is divided into A section 3, B section 4, C section 5, D section 6, E section 7, and F section 8, and the direction of each section from the start point to the end point is clockwise, of which A section 3 is forging and rolling Section B, section 4 is the finishing rolling section, section C 5 is the final rolling section, section D 6, E section 7, and F section 8 are idle rolling sections. The curve is symmetrical about the axis of the passing roll 1 and the midpoint of the idle rolling section. The shape of the pass 2 cut by the plane of the axis of the roll 1 is composed of an arc 9 and two straight lines 10 tangent to the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com