Chopstick cleaning mechanism

A technology of cleaning mechanism and chopsticks, which is applied in the direction of tableware washing machine/rinsing machine, cleaning equipment, household cleaning device, etc., can solve the problems of low work efficiency, manual cleaning, unstable cleaning effect, etc., and achieve safe and reliable cleaning process. High cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing, the utility model is further described.

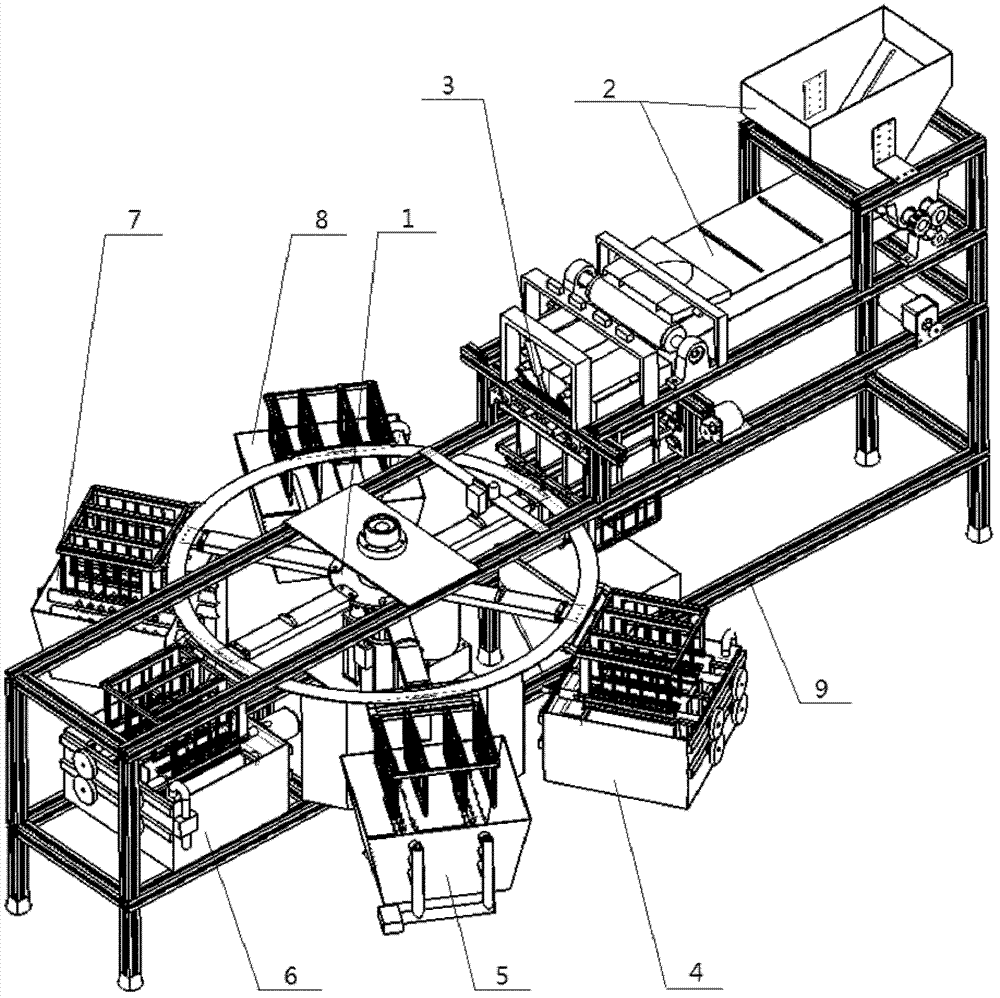

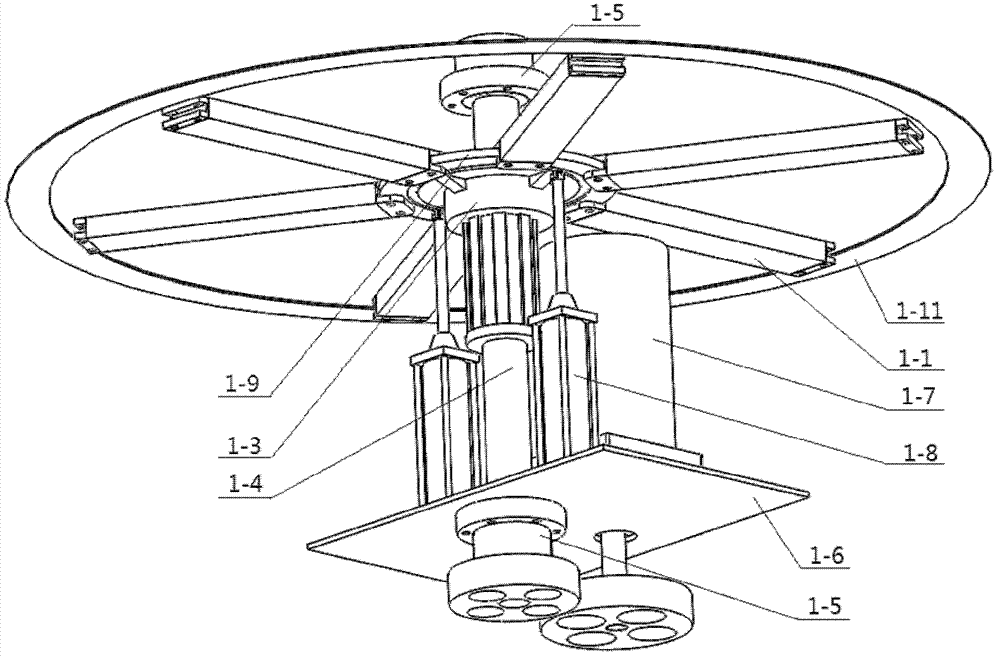

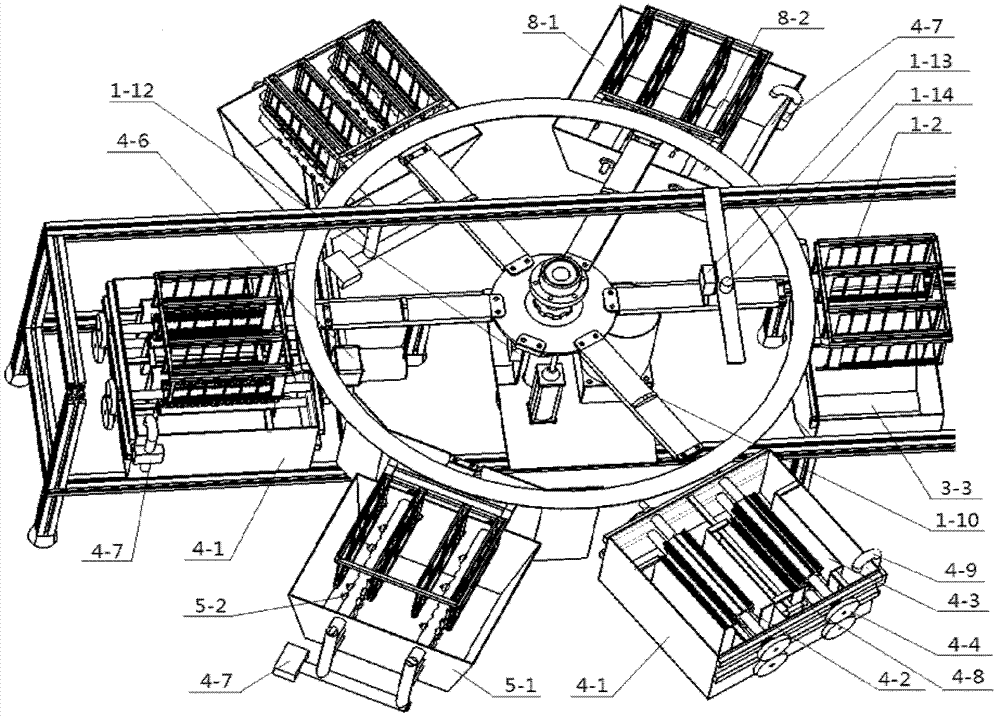

[0019] refer to Figure 1-Figure 4 , a chopsticks cleaning mechanism, the chopsticks cleaning mechanism also includes a six-station rotating cleaning mechanism 1 that can be lifted, and the six outrigger arms 1-1 of the cleaning mechanism 1 are respectively equipped with cleaning chopstick cages 1- 2. The inner end of the outrigger 1-1 is evenly installed and fixed on the spline slider 1-3, and the spline slider 1-3 can slide along the spline shaft 1-4, and the spline Axle 1-4 is fixed on the frame fixed plate by upper and lower two flange bearing seats 1-5 respectively, and frequency-adjustable gear reduction motor 1-7 is also installed on the lower frame fixed plate 1-6, described can The frequency modulation gear reduction motor 1-7 drives the rotation of the spline shaft 1-4 through gear transmission, and a large cylinder 1-8 is also installed on the lower frame fixed plate 1-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com