Photoelectric analysis method and device for gas in pipeline

A photoelectric analysis and pipeline technology, which is applied in the direction of color/spectral characteristic measurement, etc., can solve the problems of small measuring tube diameter, affecting measurement accuracy, and gas concentration can not reflect gas concentration, so as to reduce measurement error and increase measurement optical path Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

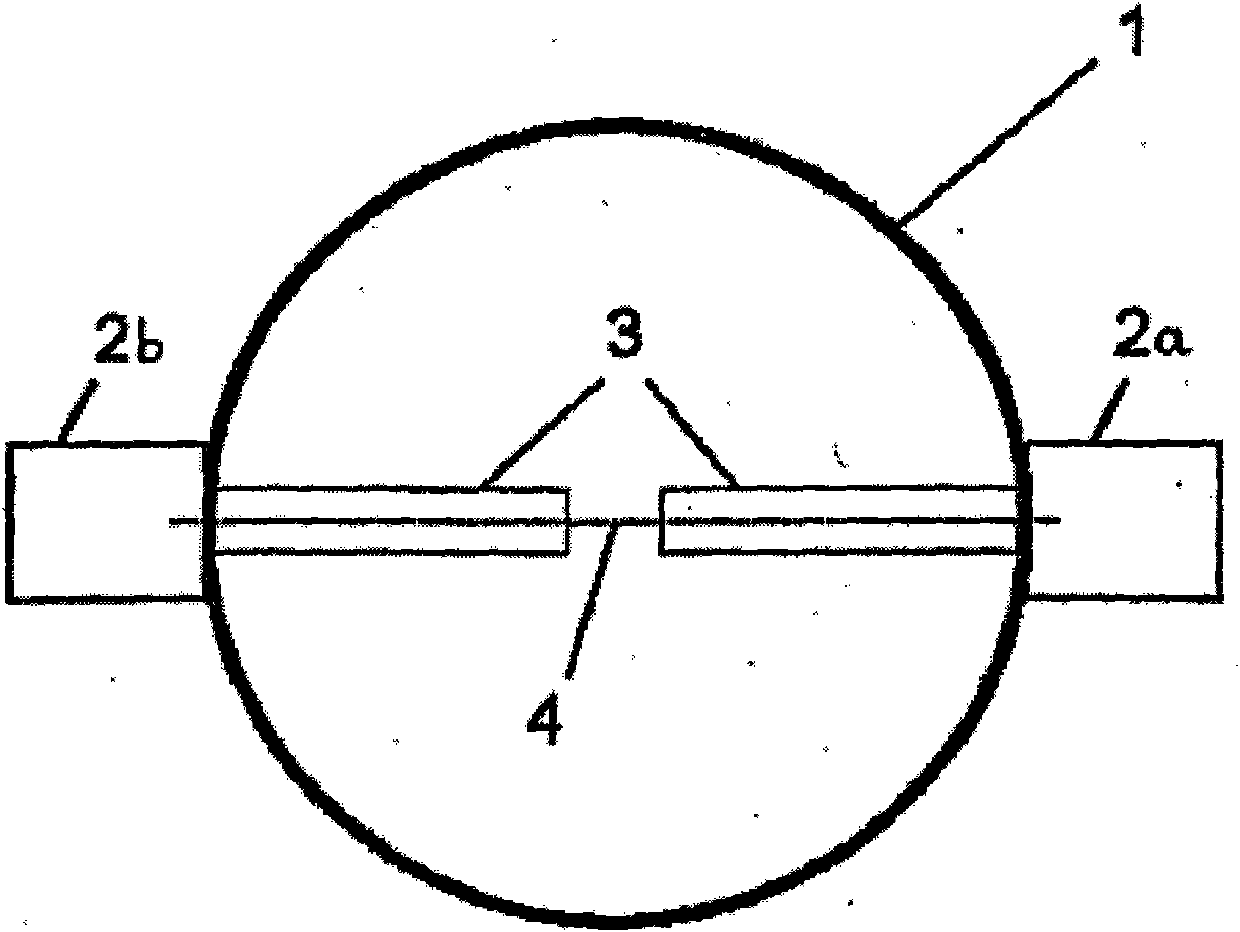

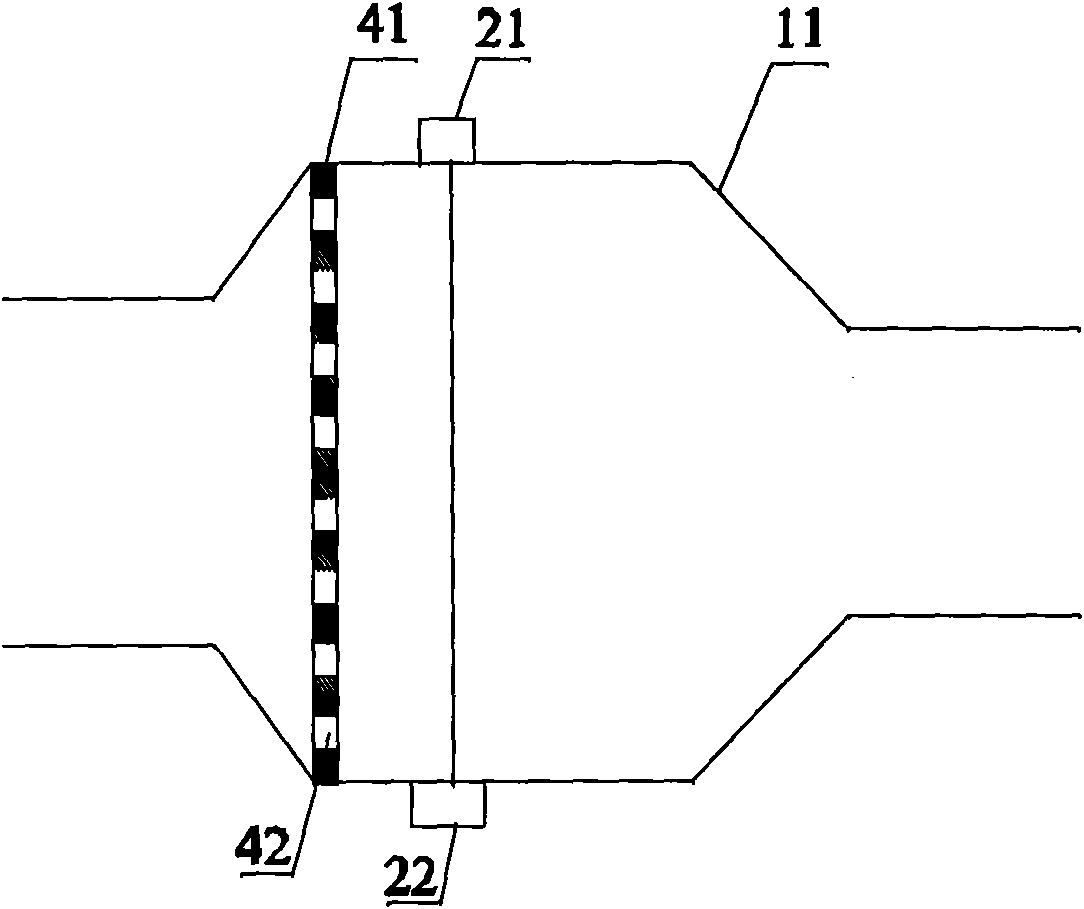

[0047] Such as figure 2 As shown, a photoelectric analysis device for the gas in the pipeline is used in the field of metallurgy to monitor the CO concentration in the pipeline. The photoelectric analysis device includes a measuring tube 11 , a flow disruptor 41 , a light source 21 , a detector 22 and an analysis unit.

[0048] The inlet and outlet of the measuring tube 11 communicate with the inside of the pipeline, so that the gas to be measured in the pipeline can flow into the measuring tube 11 by itself. The radius of the smallest covering circle of the section perpendicular to the airflow direction of the measuring tube 11 is greater than the radius of the smallest covering circle of the section of the pipe perpendicular to the airflow direction. In this embodiment, both the measuring tube 11 and the pipeline are round tubes.

[0049] Such as figure 2 As shown, the central axis of the airflow disturber 41 is parallel to the central axis of the measuring tube 11, and...

Embodiment 2

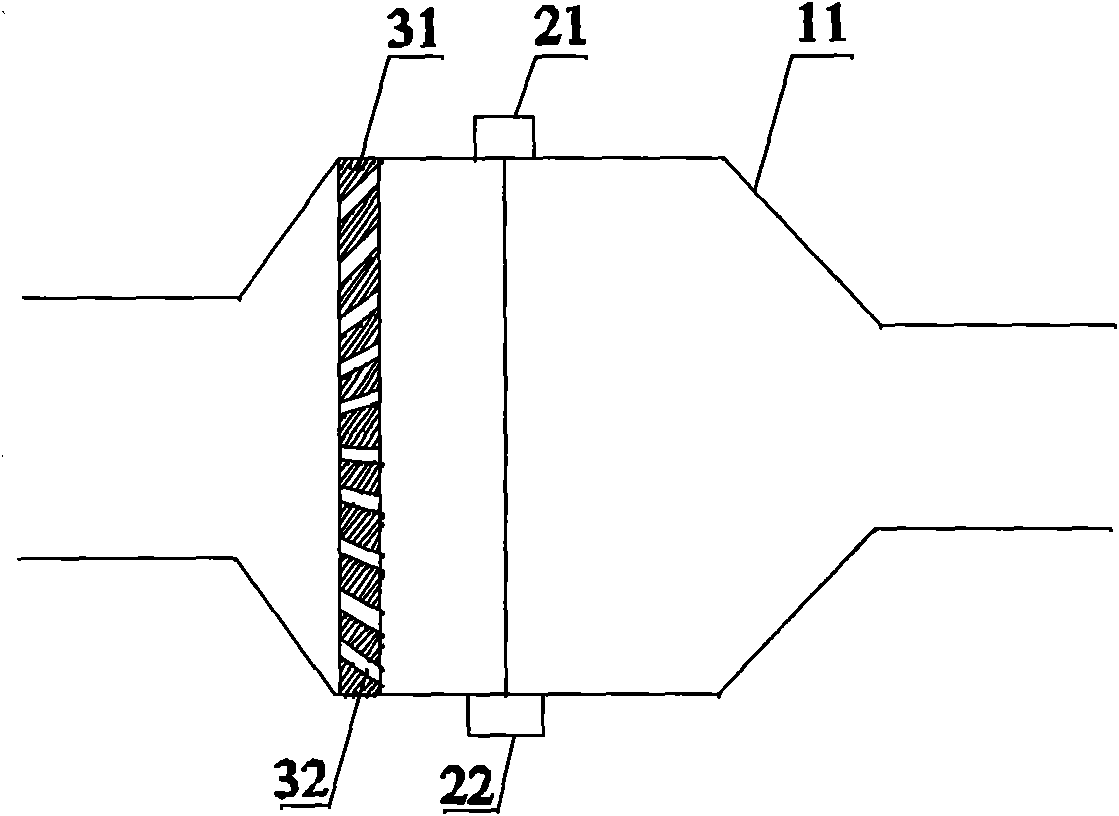

[0058] Such as image 3 As shown, a photoelectric analysis device for the gas in the pipeline is used to measure the O in the pipeline 2 Concentration, different from Example 1 is:

[0059] 1. If image 3 As shown, the included angle between the central axis of the air guide hole 32 on the airflow disturber 31 and the central axis of the measuring tube 11 is an acute angle, and the included angle gradually increases from the center to the periphery.

[0060] 2. The output wavelength of the light source 21 corresponds to O 2 the absorption spectrum lines.

[0061] Compared with the airflow disturber in Embodiment 1, the gas on the section perpendicular to the airflow direction in the upstream pipeline of the measuring tube 11 arrives at the same time, and the time difference between the light source 21 and the detector 22 on the optical path is smaller, so it can be more accurate. Accurately reflect the O in the pipeline at a certain moment 2 Concentration, better used to ...

Embodiment 3

[0067] Such as Figure 4 As shown, a photoelectric analysis device for the gas in the pipeline is used in the chemical industry to measure the CO in the pipeline 2 Concentration, different from Example 1 is:

[0068] 1. If Figure 4 As shown, the air flow disturber 51 adopts porous media.

[0069] 2. The output wavelength of the light source 21 corresponds to the CO 2 the absorption spectrum lines.

[0070] 3. If Figure 5 As shown, the cross-section of the measuring tube perpendicular to the airflow direction is a rectangle 61, and the cross-section of the pipe perpendicular to the airflow direction is a circle, but the radius R1 of the smallest covering circle of the rectangle 61 is greater than the radius of the circle R2.

[0071] This embodiment also discloses a photoelectric analysis method of gas in the pipeline, which is applied in the chemical industry to monitor the CO in the pipeline 2 Concentration, different from Example 1 is:

[0072] 1. If Figure 4 As ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com