Cuvette

A cuvette, a pair of technology, applied in the field of cuvettes, can solve the problems of reduced universality of the instrument, failure to consider the refraction utility, etc., and achieve the effect of improving sensitivity, improving sensitivity, and reducing detection limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

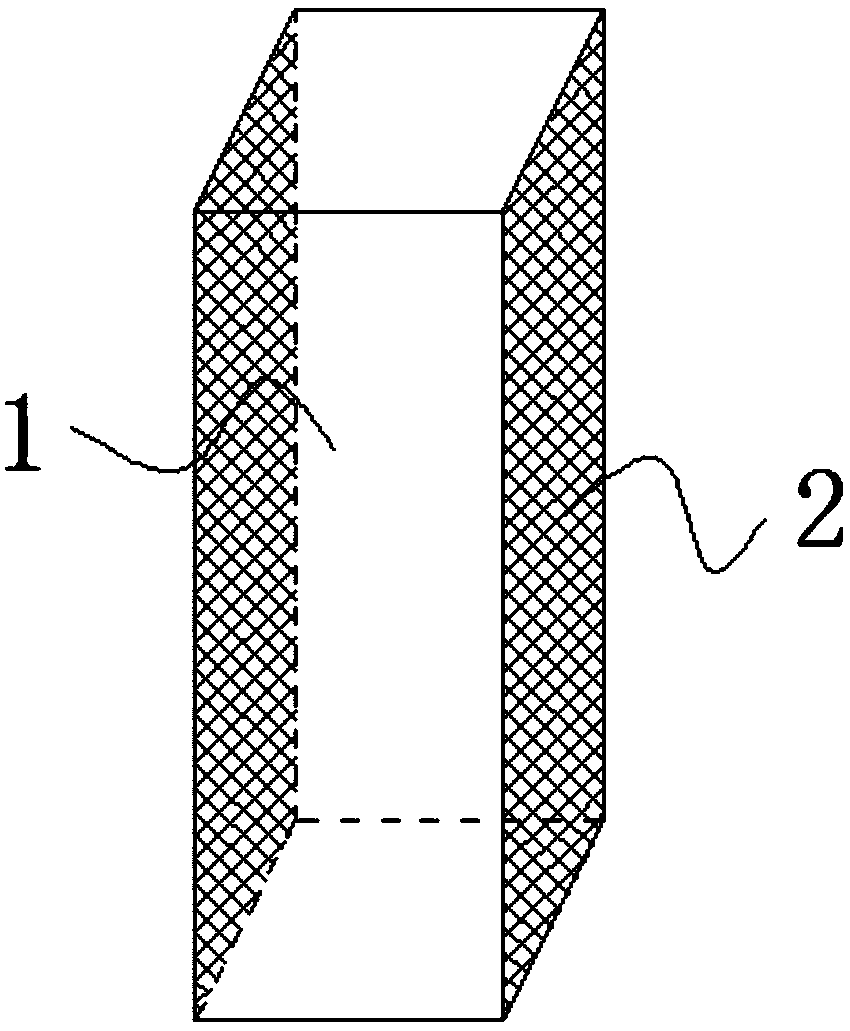

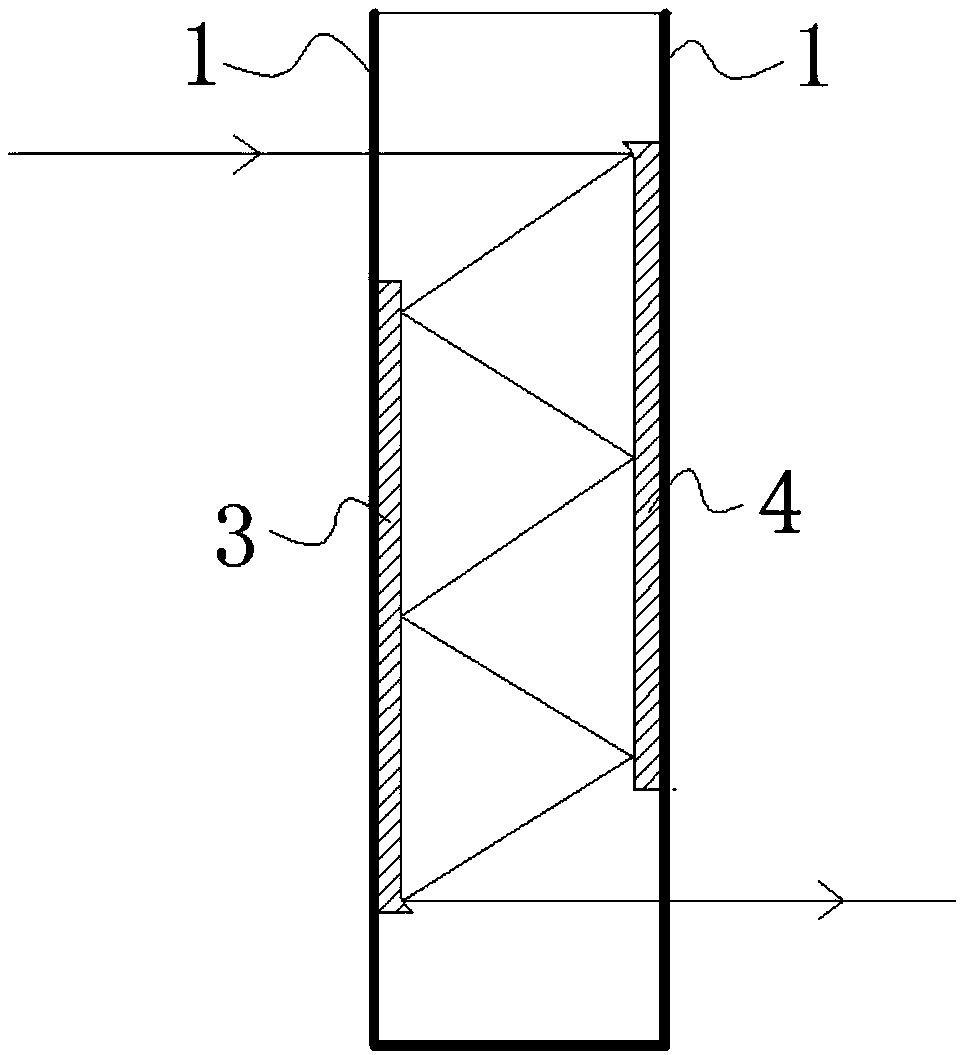

[0031] like figure 1 , 2 As shown, a cuvette has a square cylindrical structure, including a pair of parallel light-transmitting plates 1 and a pair of parallel non-light-transmitting plates 2, and the first reflective film 3 and the second reflective film 4 are respectively fixed on the On the two opposite transparent plates 1 , the first reflective film 3 and the second reflective film 4 are arranged in a staggered manner, so that light enters from the transparent plate 1 on one side and exits from the transparent plate 1 on the other side.

[0032] like figure 2 As shown, the top of the second reflective film 4 and the bottom of the first reflective film 3 in this embodiment are both in the shape of a curved arc or a broken line 5. 1 direction incident, perpendicular to the transparent plate 1 direction emission.

Embodiment 2

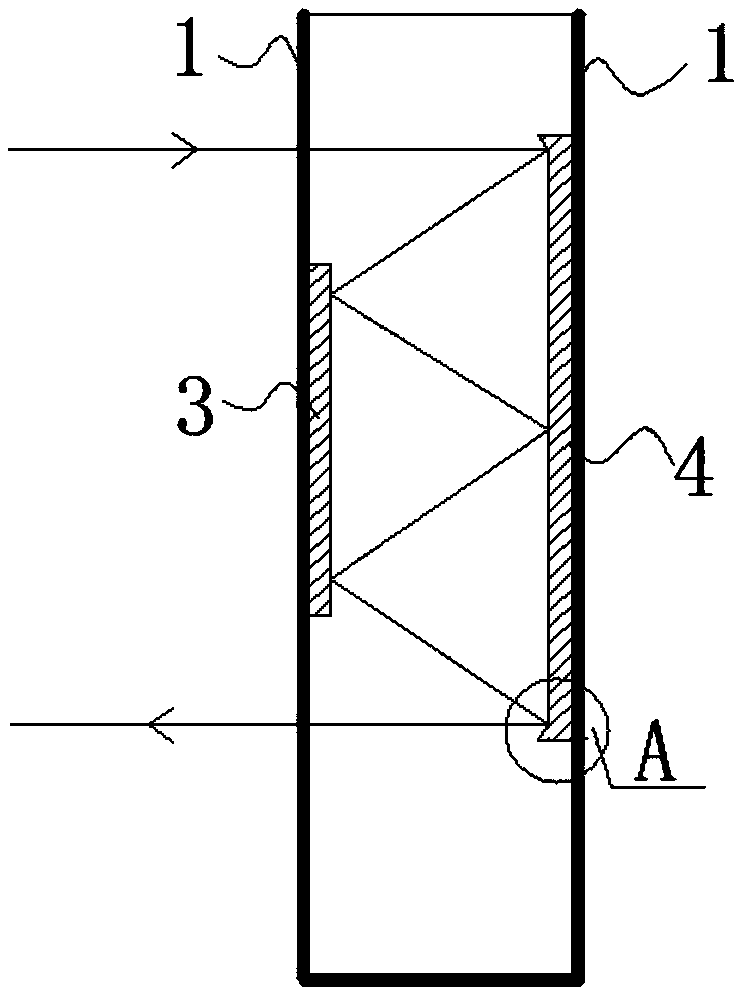

[0034] like figure 1 , 3 As shown, a cuvette has a square cylindrical structure, including a pair of parallel light-transmitting plates 1 and a pair of parallel light-transmitting plates 2, and the first reflective film 3 and the second reflective film 4 are respectively Fixed on two oppositely arranged light-transmitting plates 1, the vertical distance between the top of the first reflective film 3 and the top of the light-transmitting plate 1 is A, and the vertical distance between the bottom of the first reflecting film 3 and the bottom of the light-transmitting plate 1 is B , the vertical distance between the top of the second reflective film 4 and the top of the transparent plate 1 is a, and the vertical distance between the bottom of the second reflective film 4 and the bottom of the transparent plate 1 is b, wherein A>a, B>b.

[0035] like image 3 As shown, both sides of the second reflective film 4 are in the shape of a curved arc or a broken line 5, and the curved ...

Embodiment 3

[0037] like figure 2 As shown, a cuvette has a square cylindrical structure and includes two pairs of light-transmitting plates 1 arranged in parallel. The first reflective film 3 and the second reflective film 4 are respectively fixed on a pair of mutually parallel light-transmitting plates 1 , and the first reflective film 3 and the second reflective film 4 are mutually staggered so that light enters from one side of the light-transmitting plate 1 and the other side of the light-transmitting plate 1 emits.

[0038] In this embodiment, the top of the second reflective film 3 and the bottom of the first reflective film 4 are in the shape of a curved arc or a broken line 5, so that light can be incident along a direction perpendicular to the light-transmitting plate 1, and perpendicular to the light-transmitting plate 1 Direction shot.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com