Vacuum cleaner soft pipe component and vacuum cleaner

A technology for vacuum cleaners and hose assemblies, which is applied in the direction of vacuum cleaners, suction hoses, household appliances, etc., and can solve problems such as conduction state failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

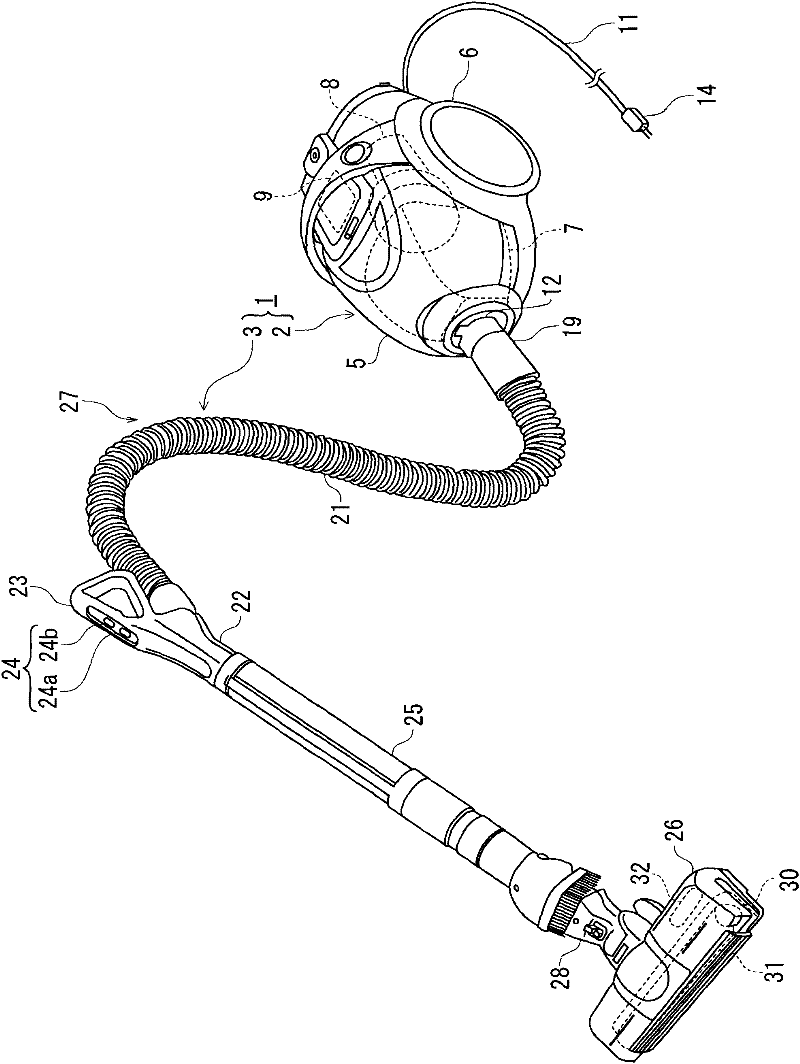

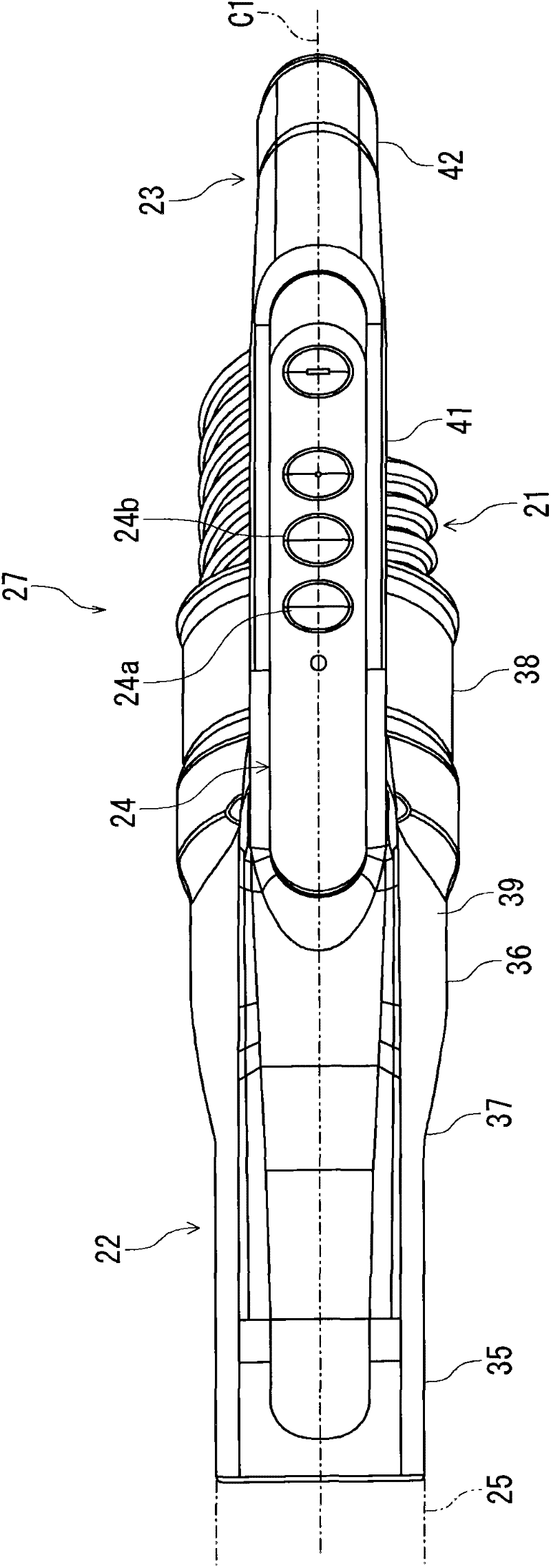

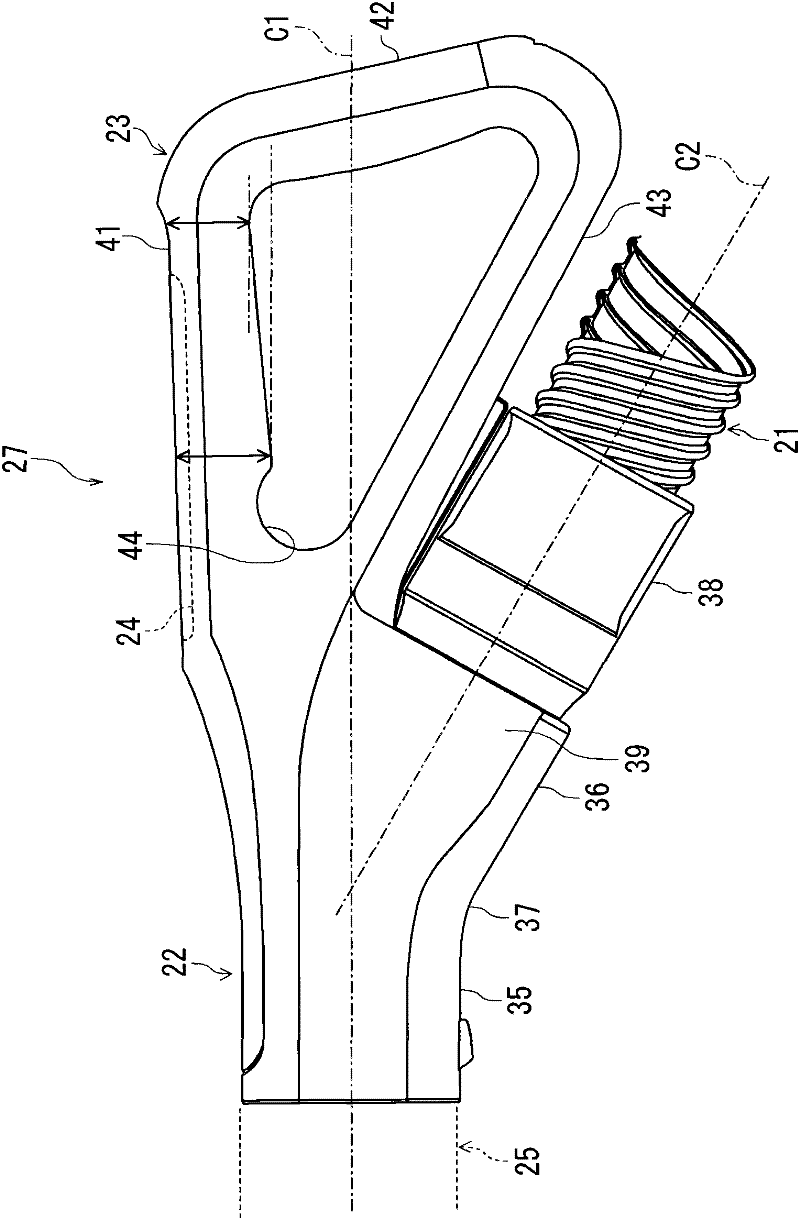

[0022] The following will refer to Figure 1-6 Embodiments of a vacuum cleaner hose assembly and a vacuum cleaner according to the present invention are described. It is to be noted that the terms "up", "down", "right", "left" and similar terms denoting directions are used in this specification with reference to the state shown in the drawings, or with figure 1 Use the actual usable state of the vacuum cleaner.

[0023] refer to figure 1 , which shows a perspective view of a vacuum cleaner according to one embodiment, the vacuum cleaner 1 being a so-called canister-type vacuum cleaner.

[0024] The vacuum cleaner 1 includes a vacuum cleaner body 2 freely movable on a cleaning surface (surface to be cleaned) and a pipe unit 3 connected to the vacuum cleaner body 2 in a detachable manner.

[0025] The vacuum cleaner body 2 includes a body case 5, a pair of wheels 6 pivotably supported on both sides of the body case 5, a dust separation / collection unit 7 detachably mounted to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com