Temperature sorting device

A technology of sorting device and intermediate frequency furnace, which is applied in sorting and other directions, and can solve problems such as workpiece circulation and inability to achieve precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

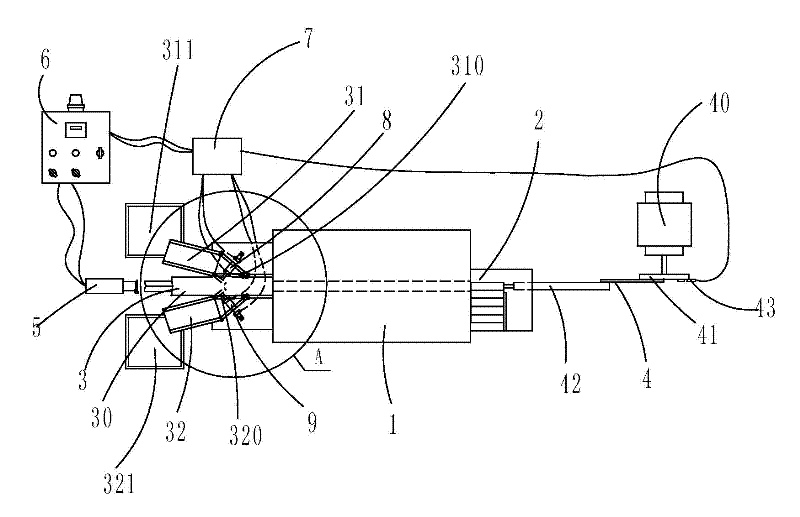

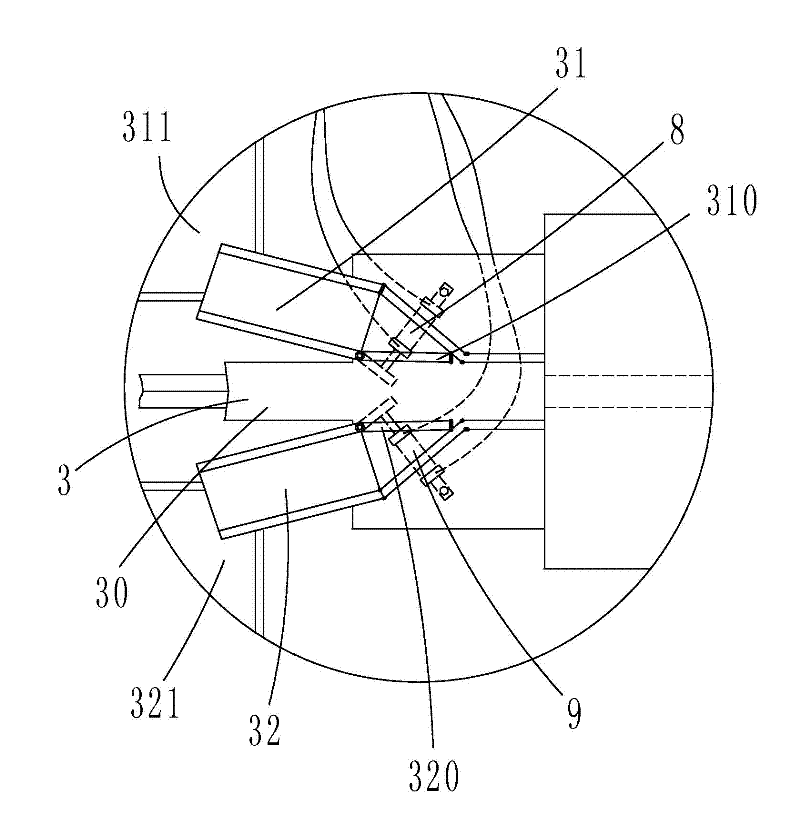

[0010] see figure 1 and figure 2 , a temperature sorting device, which includes: an intermediate frequency furnace 1, a feed port 2 arranged at one end of the intermediate frequency furnace 1, a discharge port 3 arranged at the other section of the intermediate frequency furnace, an eccentric wheel pushing mechanism 4, an infrared thermometer 5. The temperature monitoring and alarm system 6 connected to the infrared thermometer 5, the PLC control circuit 7 connected to the temperature monitoring and alarm system 6, the first cylinder 8 and the second cylinder 9 connected to the PLC control circuit 7, the The discharge port 3 includes: a qualified material outlet 30, a low-temperature material outlet 31 arranged on one side of the qualified material outlet 30, and an overburned material outlet 32 arranged on the other side of the qualified material outlet 30. One end of the low-temperature material outlet 31 A first movable baffle 310 is provided, and the first movable baff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com