Low-temperature impact resistant 42CrMoVNb steel for wind-power variable propeller and yaw bearing ring

A technology of yaw bearing and low temperature resistance, which is applied in the field of alloy structural steel, can solve the problems that alloy steel 42CrM cannot meet, and achieve the effect of improving impact resistance and refining structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

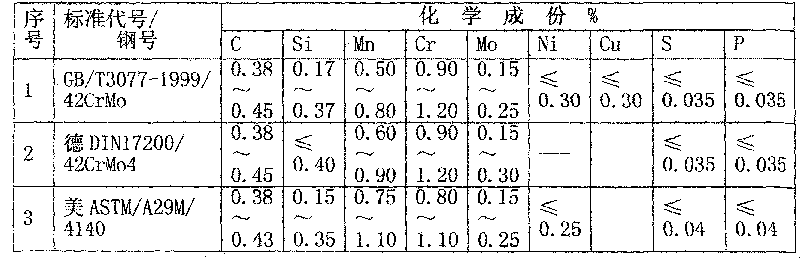

[0033] In this embodiment, 42CrM is used for wind power variable pitch and yaw bearing rings resistant to low temperature impact o VN b Steel, consisting of the following components and contents (by weight percentage):

[0034] C: 0.43 Si: 0.26 Mn: 0.74 Cr: 1.03

[0035] Mo: 0.16 Ni: 0.4 V: 0.10 Nb: 0.045

[0036] Cu: 0.08 Al: 0.023 S: 0.010 P: 0.008

[0037] As: 0.011 Sn: 0.007 [O]: 18PPM [H]: 1.7PPM

[0038] The rest is Fe and normal impurities.

[0039] 42CrM for wind power variable pitch and yaw bearing rings with the above components and content of low temperature impact resistance o VN b A method for smelting steel, comprising the following steps:

[0040] 1) EBT electric furnace with eccentric furnace bottom tapping method is adopted, and steelmaking pig iron and steel scrap are added; 2) Submerged arc barrel furnace LF ladle is adopted, and the Ar flow rate of argon gas is 0.1~0.5m 3 / min, refining outside the furnace, adding Fe-v, Fe-Nb, Fe-Mn, Fe-Cr and othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com