Hard rod type gear-changing system for transmission gear

A hard rod type, gearbox technology, applied to components with teeth, belts/chains/gears, mechanical equipment, etc., can solve the problems of poor adjustment adaptability, gear disengagement, easy shaking of the shift handle, etc., to achieve increased shifting The effects of smoothness of gears, improvement of gear shift feel, reduction of jitter and probability of disengagement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

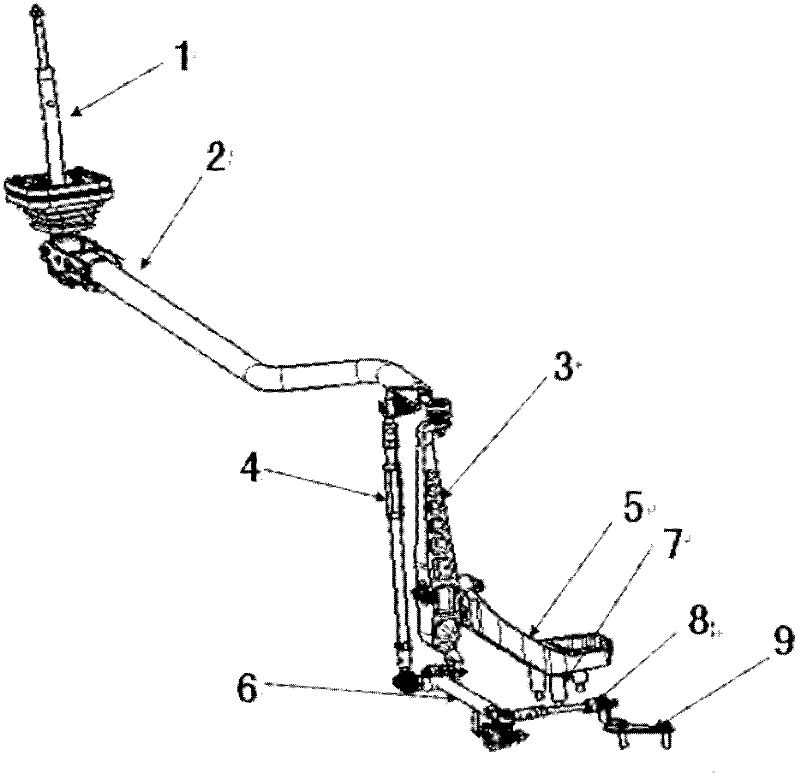

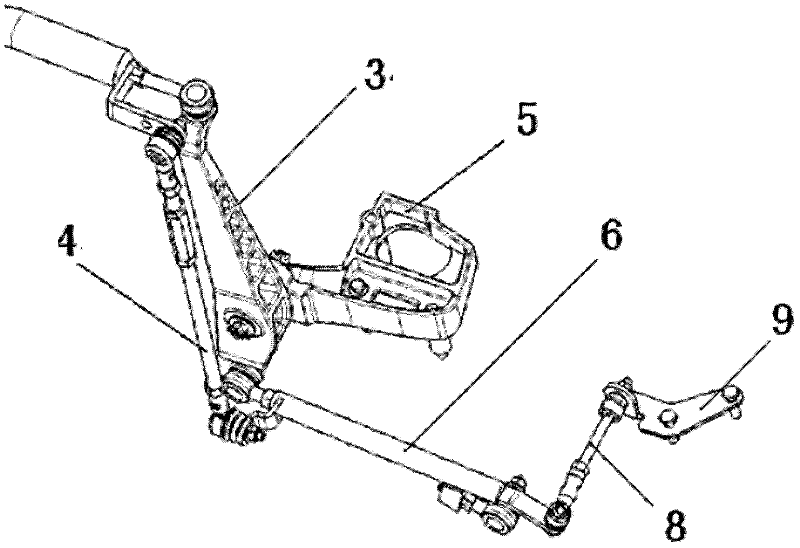

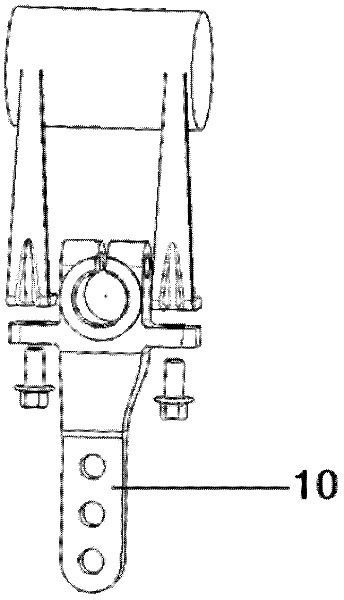

[0020] Such as Figure 1-3 As shown, the technical solution provided by the present invention is a hard rod shift system for a gearbox, the hard rod shift system is a single hard rod shift system, including an operating mechanism 1, a telescopic rod assembly 2. Gear shift assembly and gear selection assembly, the operating mechanism is connected with the telescopic rod assembly 2 through a ball joint or a rotating pair, and the telescopic rod assembly 2 is connected with the gear shift assembly and the telescopic rod assembly 2 respectively. The gear selection assembly is connected through a ball joint or a rotating pair, and the end of the telescopic rod assembly 2 is provided with a plurality of mounting holes. A plurality of mounting holes provided on the telescopic rod assembly 2 are arranged axially in sequence. The shift assembly includes a shift arm 3 and a shift arm support assembly 5 connected to the shift arm 3, and the shift arm support assembly 5 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com