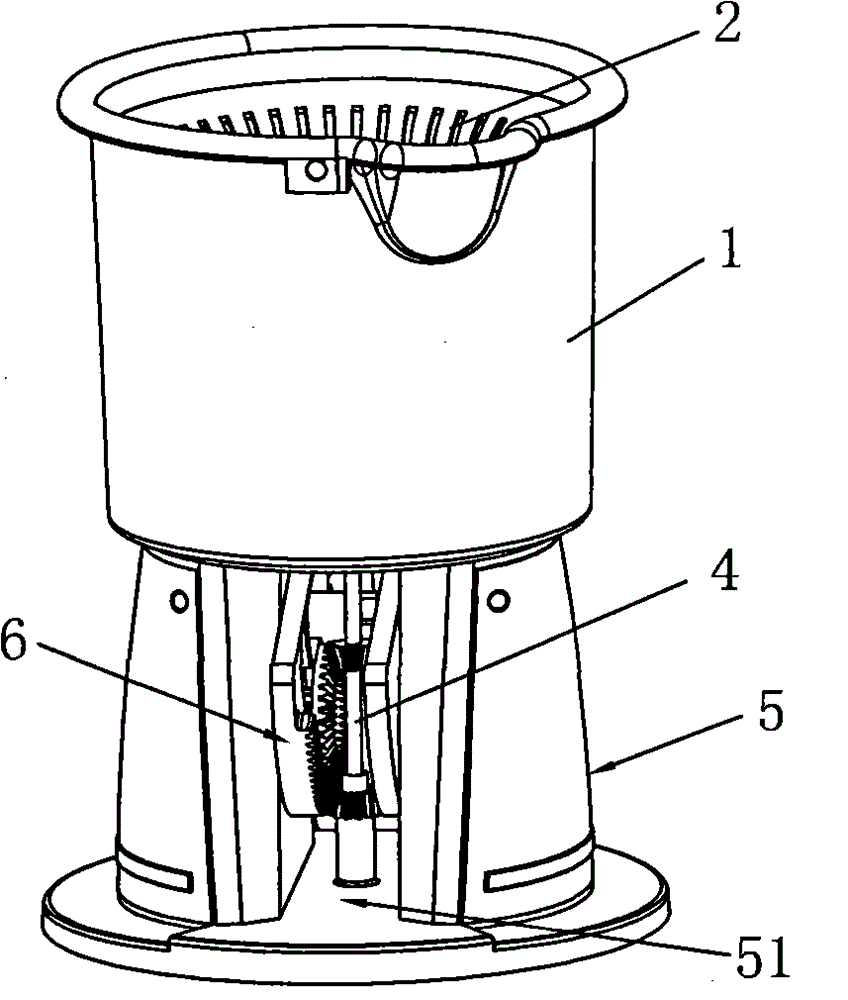

A kind of two-pedal pedal sports washing machine

A double-pedal pedal-type washing machine technology, which is applied to washing machines with containers, sports accessories, washing devices, etc., can solve the problems of complex structure, high maintenance rate, easy damage, etc., to simplify the clutch transmission structure and save production. and the effect of installation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

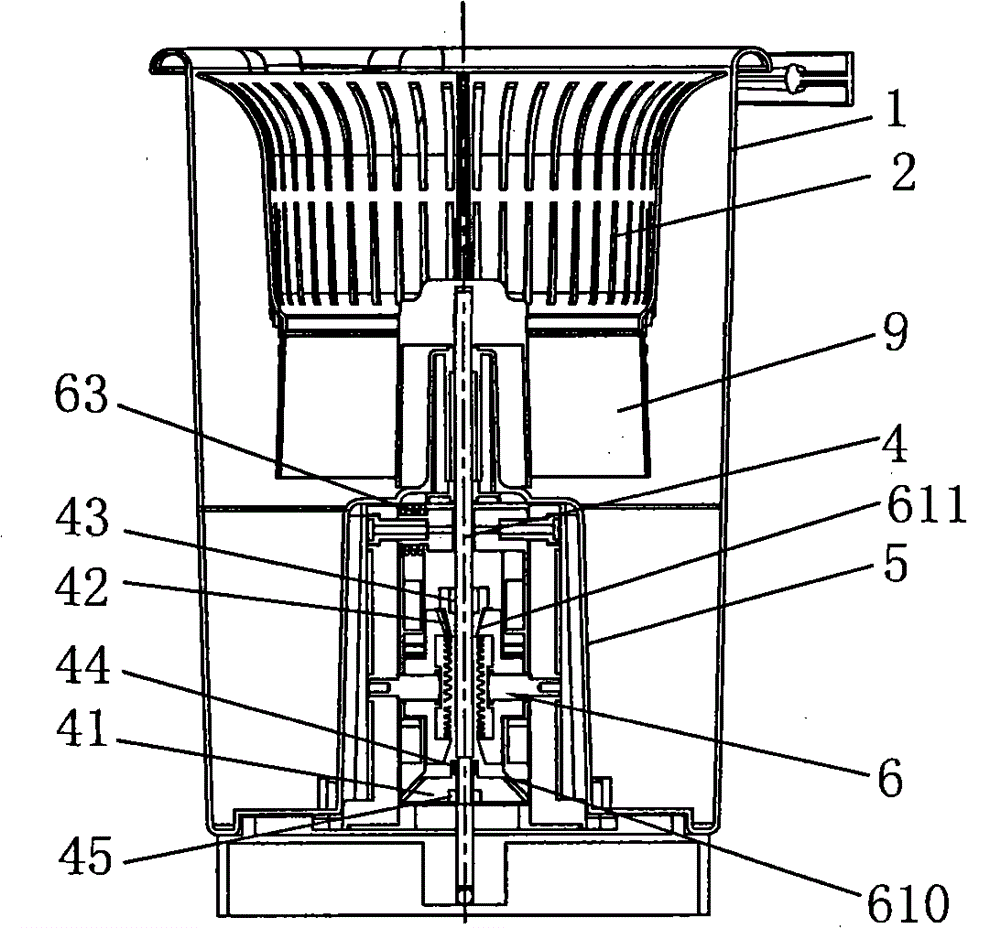

[0039] Such as figure 2 As mentioned above, the output shaft 4 described in this embodiment is fixedly connected with the inner bucket 2, and the bottom of the inner bucket 2 is integrally provided with a pulsator and / or a convex rib is provided on the side wall.

Embodiment 2

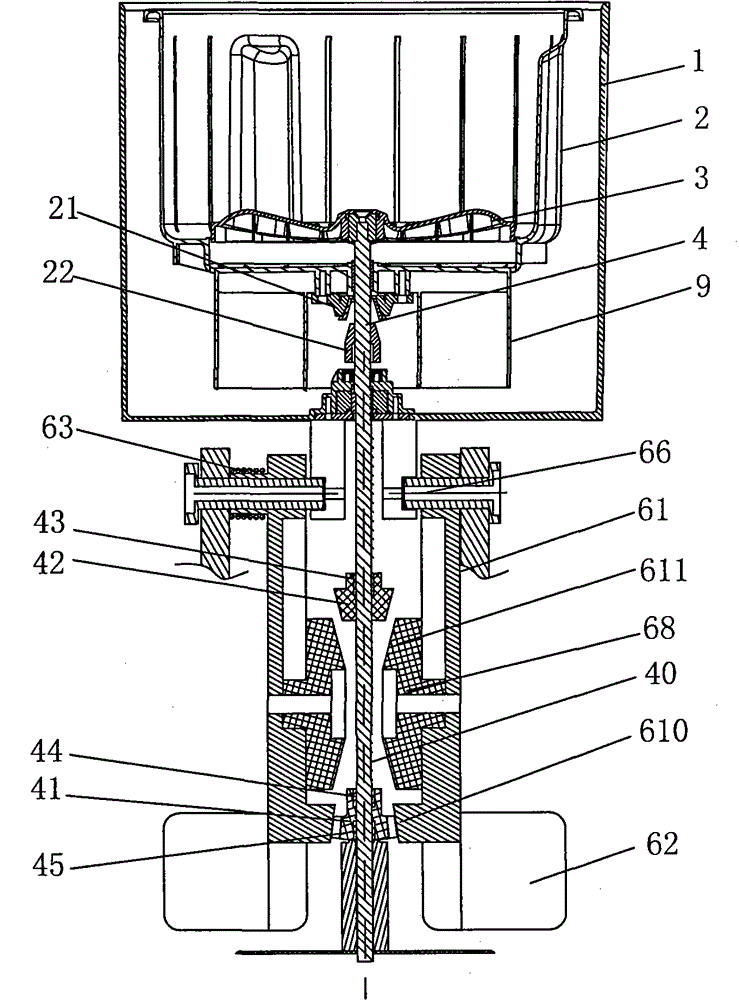

[0041] Such as image 3 and Figure 4 As shown, the inner barrel 2 described in this embodiment is provided with a pulsator 3, the output shaft 4 is fixedly connected with the pulsator 3, the bottom of the inner barrel 2 is provided with an inner spline 21, and an outer spline 22 is arranged corresponding to the output shaft 4 , The inner spline 21 and the outer spline 22 are separated during washing, and meshed during dehydration so that the pulsator 3, the inner tub 2 and the output shaft 4 are integrated.

Embodiment 3

[0044] Such as Figure 2 to Figure 4 As shown, the lifting mechanism described in this embodiment is a buoy 9 arranged below the inner tub 2 .

[0045] This embodiment can be directly combined with Embodiment 1.

[0046] When combined with embodiment two, refer to image 3 , Figure 4 The buoy 9 drives the inner barrel 2 to float up, including two stages. The first stage is that the buoy 9 first drives the inner barrel 2 to float up alone, and the pulsator 3 and the output shaft 4 do not move. This stage corresponds to the separation of the inner spline 21 and the outer spline 22. The inner barrel 2 and the output shaft 4 are relatively free; the second stage is that the buoy 9 continues to drive the inner barrel 2 to float up, and at the same time drives the wave wheel 3 and the output shaft 4 to move upward. This stage corresponds to the transmission of the pedal mechanism 6 and the washing bevel gear 41 to drive Output shaft 4 rotates.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com