Transmission system for sports washing machine and washing machine

A transmission system and washing machine technology, applied in the field of washing machines, can solve the problems of the negative impact of vibration and noise of washing machines, reduce the performance of washing machines, and asymmetric stress of washing machines, and achieve zero consumption, reduce vibration and noise, and ensure concentricity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

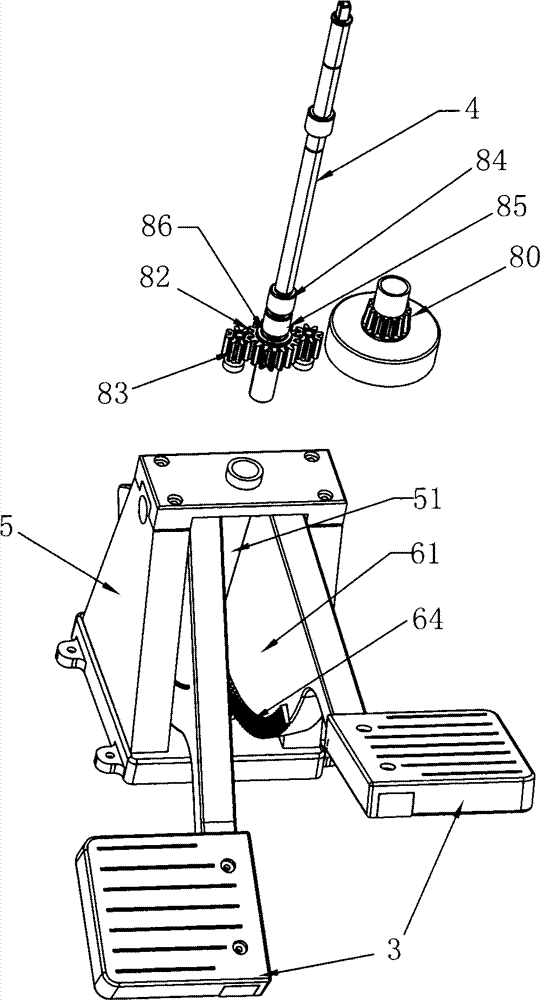

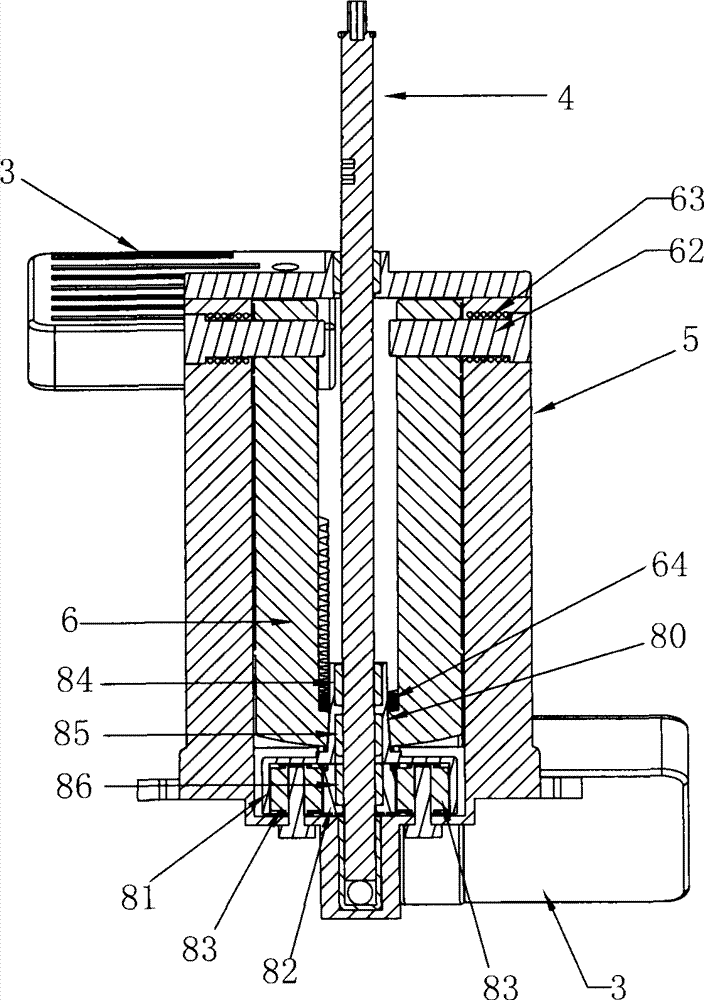

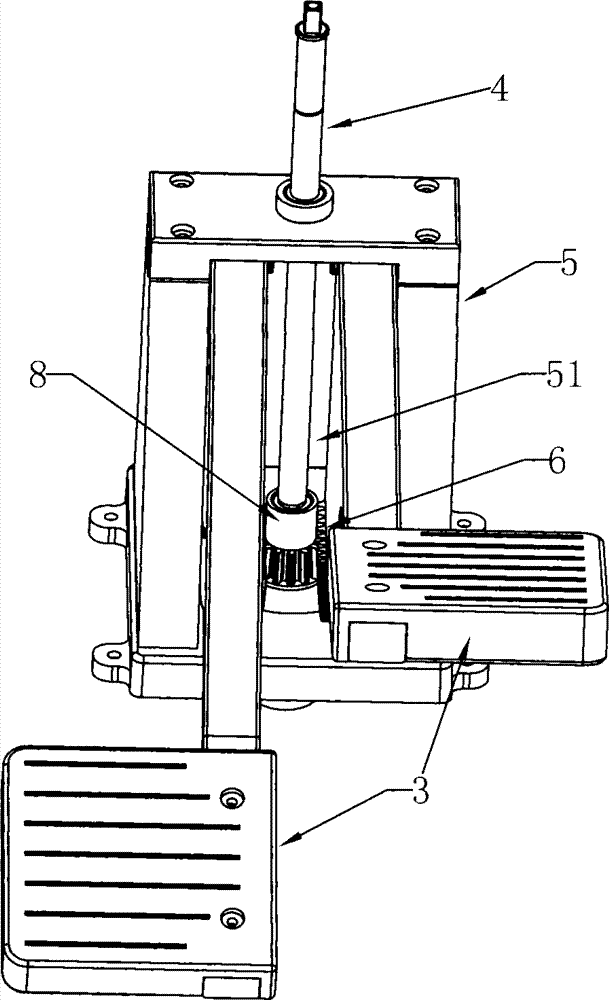

[0042] Such as Figure 1 to Figure 6 As shown, the inner ring gear 81 described in this embodiment is below the external gear 80, the first one-way bearing 84, the second one-way bearing 85 and the third one-way bearing 86 are arranged sequentially from top to bottom, and the groove section is The distance between the upper and lower two groove segments 40, 41 satisfies the requirement that the output shaft 4 moves up and down, three one-way bearings and only one one-way bearing loses its function.

[0043] During washing, the output shaft 4 moves upwards, the third one-way bearing 86 is in the lower groove section 41, and the first one-way bearing 84 and the second one-way bearing 85 are in the output shaft between the upper and lower two groove sections 40,41. 4, at this time, the third one-way bearing 86 has no effect on the output shaft 4, while the first one-way bearing 84 and the second one-way bearing 85 act in opposite directions on the output shaft 4, and the transmis...

Embodiment 2

[0046] Such as Figure 7 and Figure 8 As shown, the output shaft described in this embodiment is provided with a groove section 42, the inner ring gear 81 is above the external gear 80 (opposite to the direction of Embodiment 1), the third one-way bearing 86, the first one-way bearing 84 and the second one-way bearing 85 are arranged sequentially from top to bottom.

[0047] During washing, the output shaft 4 moves upwards, the third one-way bearing 86 is in the groove section 42, and the first one-way bearing 84 and the second one-way bearing 85 are on the normal action section of the output shaft 4. At this time, the third The one-way bearing 86 has no effect on the output shaft 4, while the first one-way bearing 84 and the second one-way bearing 85 act on the output shaft 4 in opposite directions. Forward and reverse to achieve washing.

[0048] During dehydration, the output shaft 4 moves downward, the first one-way bearing 84 is in the groove segment 42, the second on...

Embodiment 3

[0051] Such as figure 1 , image 3 and Figure 5 As shown, the transmission gear 64 in this embodiment is an arc-shaped rack arranged on the edge of the arc-shaped plate, and this structure can be used in combination with Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com