Waste heat recovery and material drying energy-saving system for intelligent environmental-friendly injection molding machine

A waste heat recovery and energy-saving system technology, applied in the field of auxiliary equipment of injection molding machines, can solve the problems of clogging of the drying barrel, partial pump extrusion of the heat collecting cover, no storage box, etc., and achieve the effect of good drying material.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

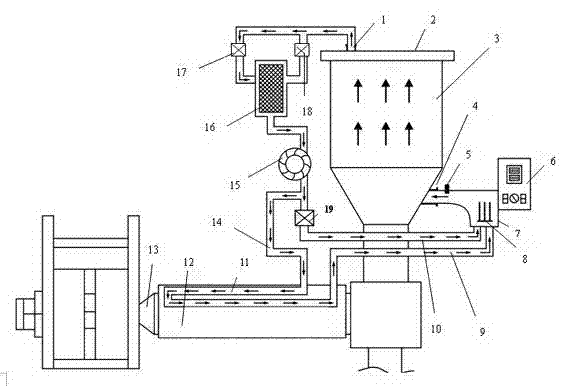

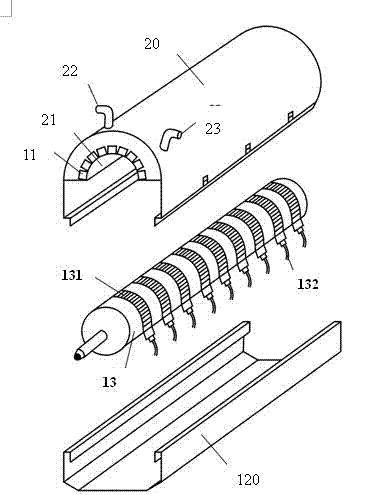

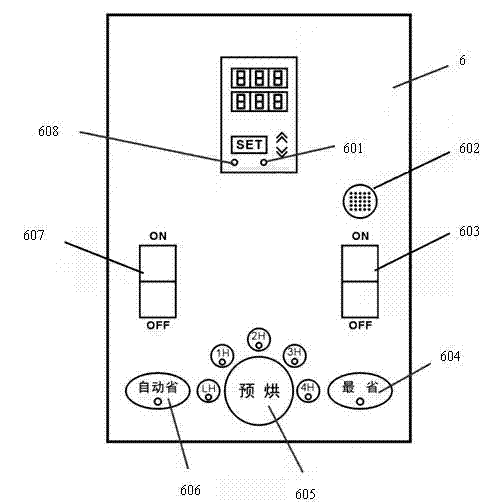

[0041] a. Generally, when starting the injection molding machine to pre-bake the material, first turn on the electric heating coil 131 on the gun barrel 13, then turn on the main power switch 603 and the auxiliary heating power switch 607 on the intelligent electric control box 6, and automatically enter "automatic" when starting up the machine. File "state work, set a temperature on intelligent thermostat 60 according to plastic particle simultaneously. As the barrel heating ring 131 is continuously heated, the emitted heat is absorbed by the heat collecting tube 11 in the heat preservation heat collecting device 20, and the hot air is sent to the fluid collector 7 where the auxiliary heater 8 is located under the pressure of the air pump 15 When entering the drying barrel to bake the material, it generally takes 1 to 3 hours of pre-drying time.

[0042] b. In special circumstances, when the injection molding machine is turned on to pre-bake the material, when the barrel heat...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap