Hydraulic control power cutting device of down-hole trackless rubber-tyred car

A technology for trackless rubber-tyred vehicles and power cut-off, applied in the direction of hydraulic brake transmission devices, etc., can solve problems such as wear of brakes, friction plates and transmission shafts, and achieve the effect of reasonable structure and good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

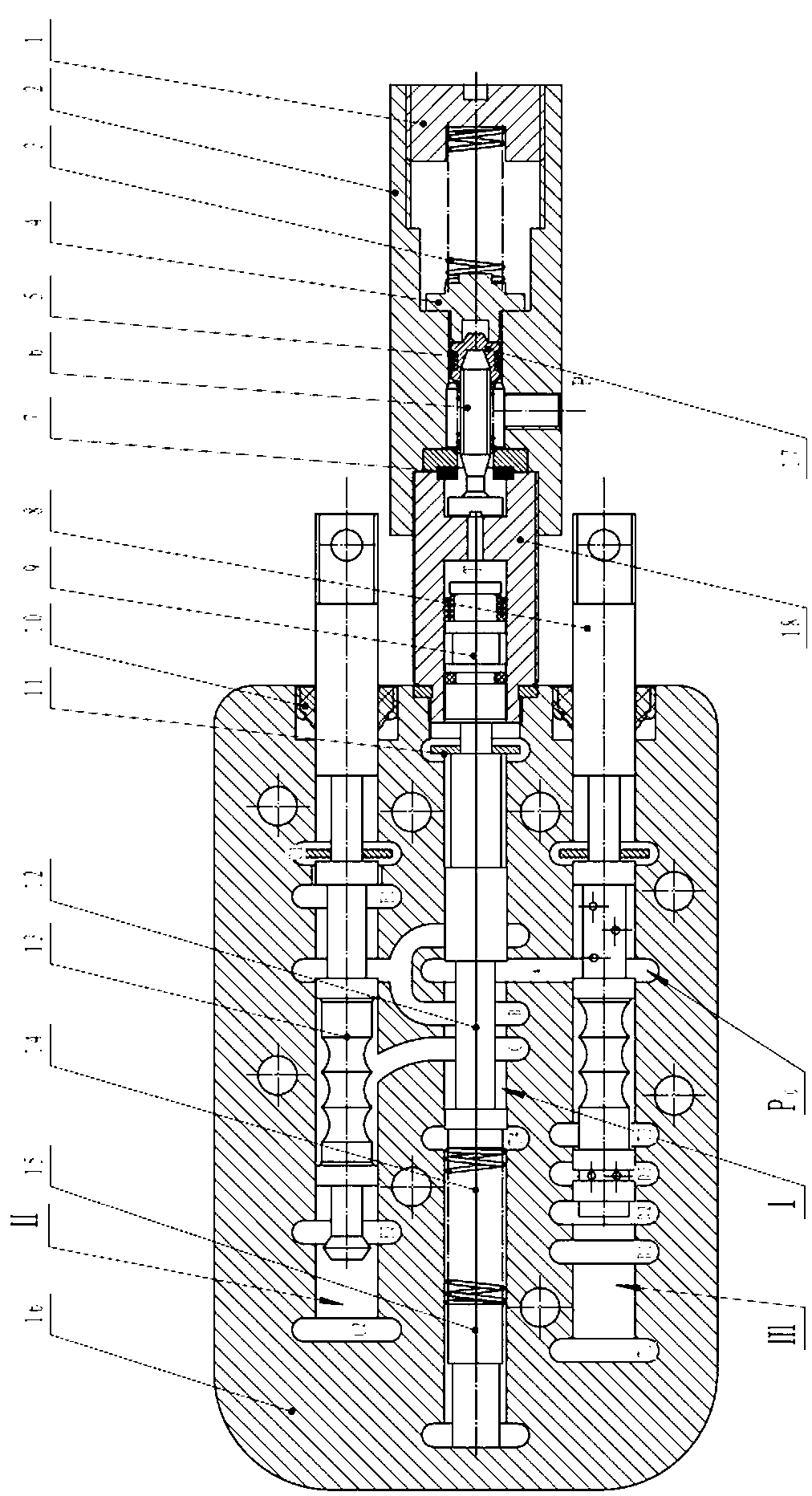

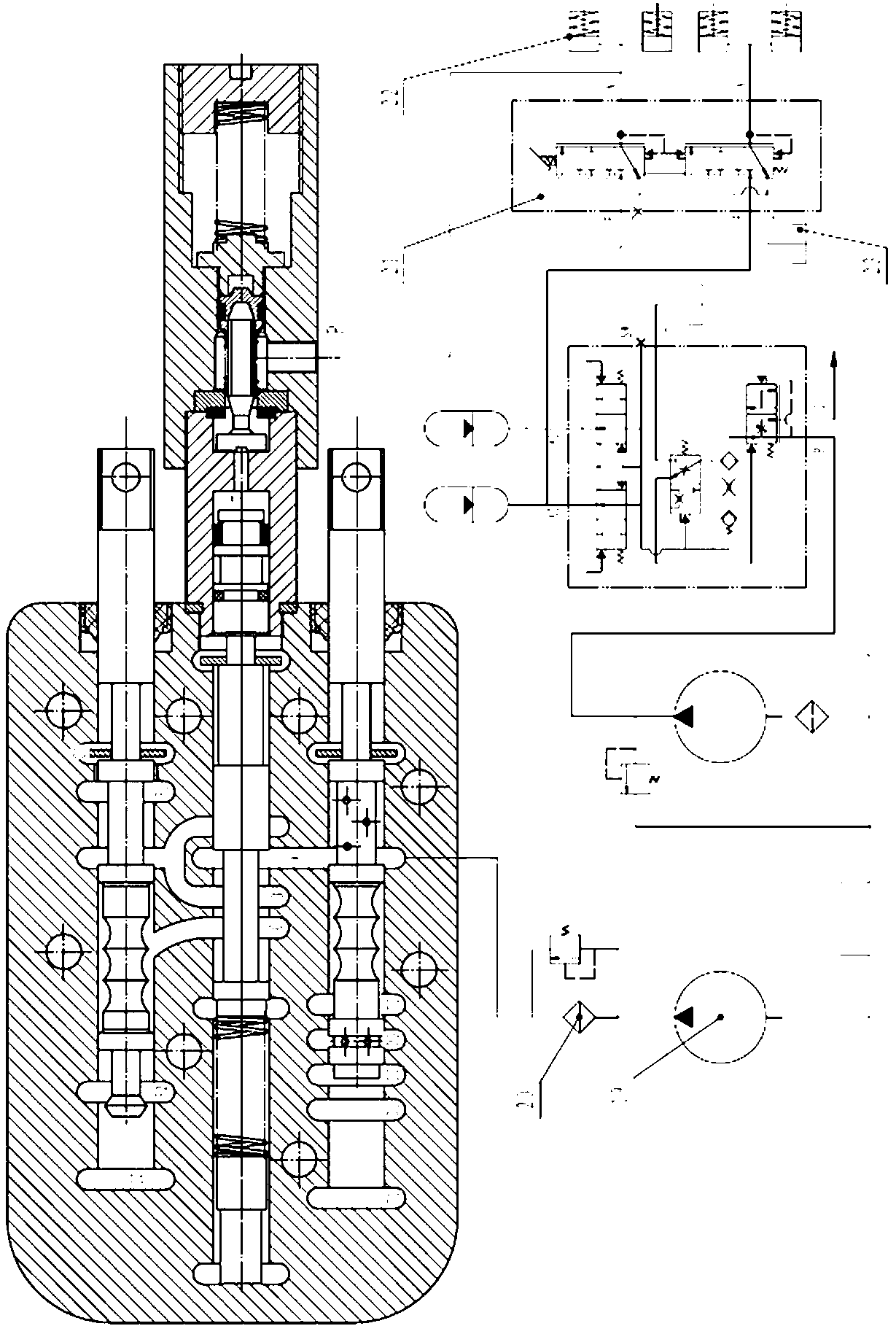

[0026] The specific embodiment of the present invention will be further described in conjunction with the accompanying drawings.

[0027] The hydraulically controlled power cut-off device of the present invention includes valve body I, valve body II, valve body III, reversing control valve 13, shift control valve 8 and power cut-off valve assembly;

[0028] The power cut-off components include a pressure adjustment nut 1, a pressure regulating spring 3, a limit block 4, a Y-shaped seal 5, a nylon seal 7, a hydraulic valve core 6, a hydraulic piston 9, a limit plate 11, and a power cut-off valve stem. 12.

[0029] Return spring 14, base 15, connecting block 17.

[0030] Working process: (shift process): When the shift control lever is placed in the first gear position, the shift control valve 8 moves to the left for a corresponding distance, and the transmission oil output from the transmission pump 19 passes through the filter 20 from the After entering the valve body I, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com