Method for adhering protection tape, and protection tape used in the method

A technology of protective tape and sticking roller, used in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as breakage, poor adsorption, and wafer falling, and achieve the effect of suppressing warpage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

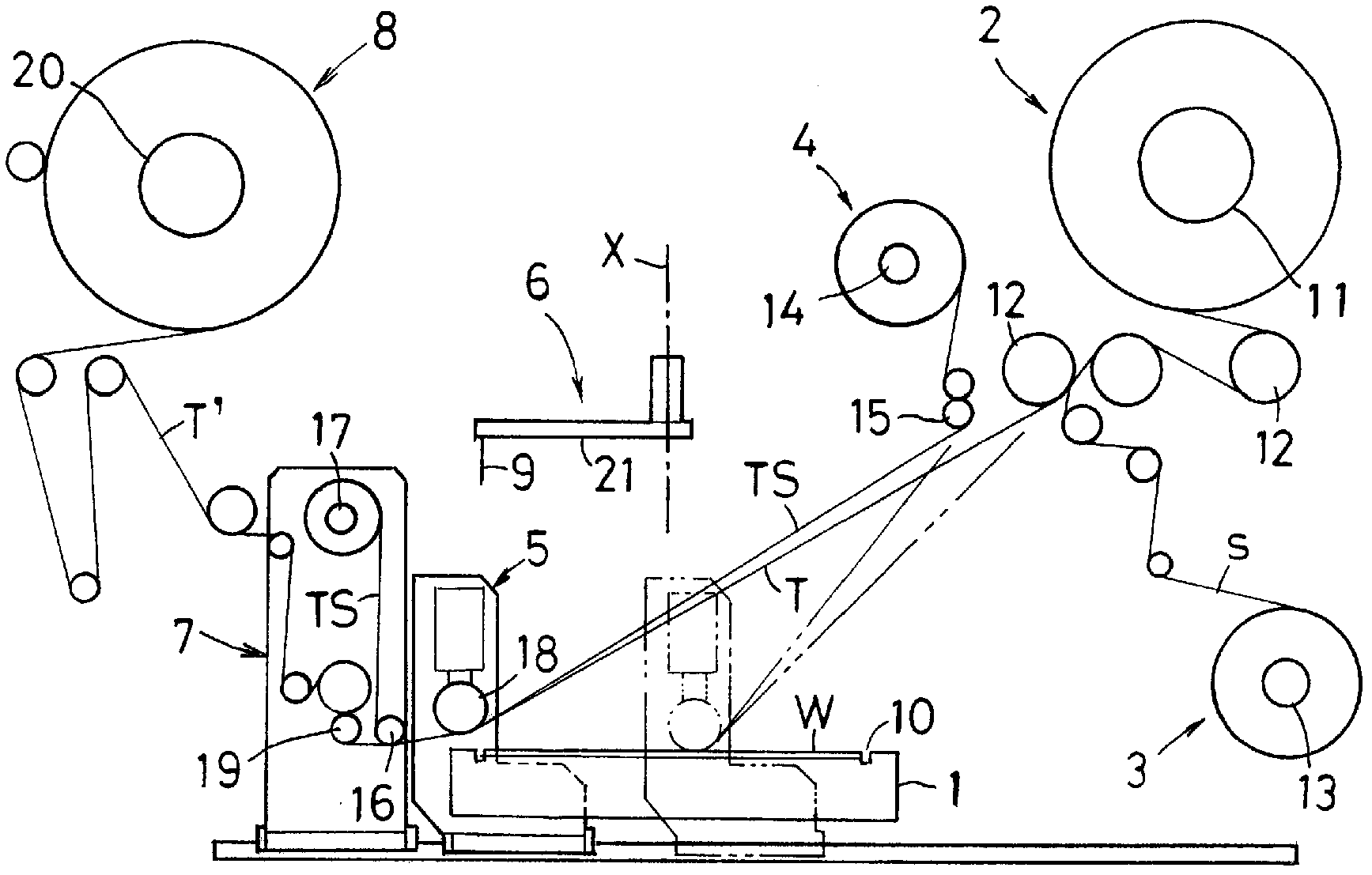

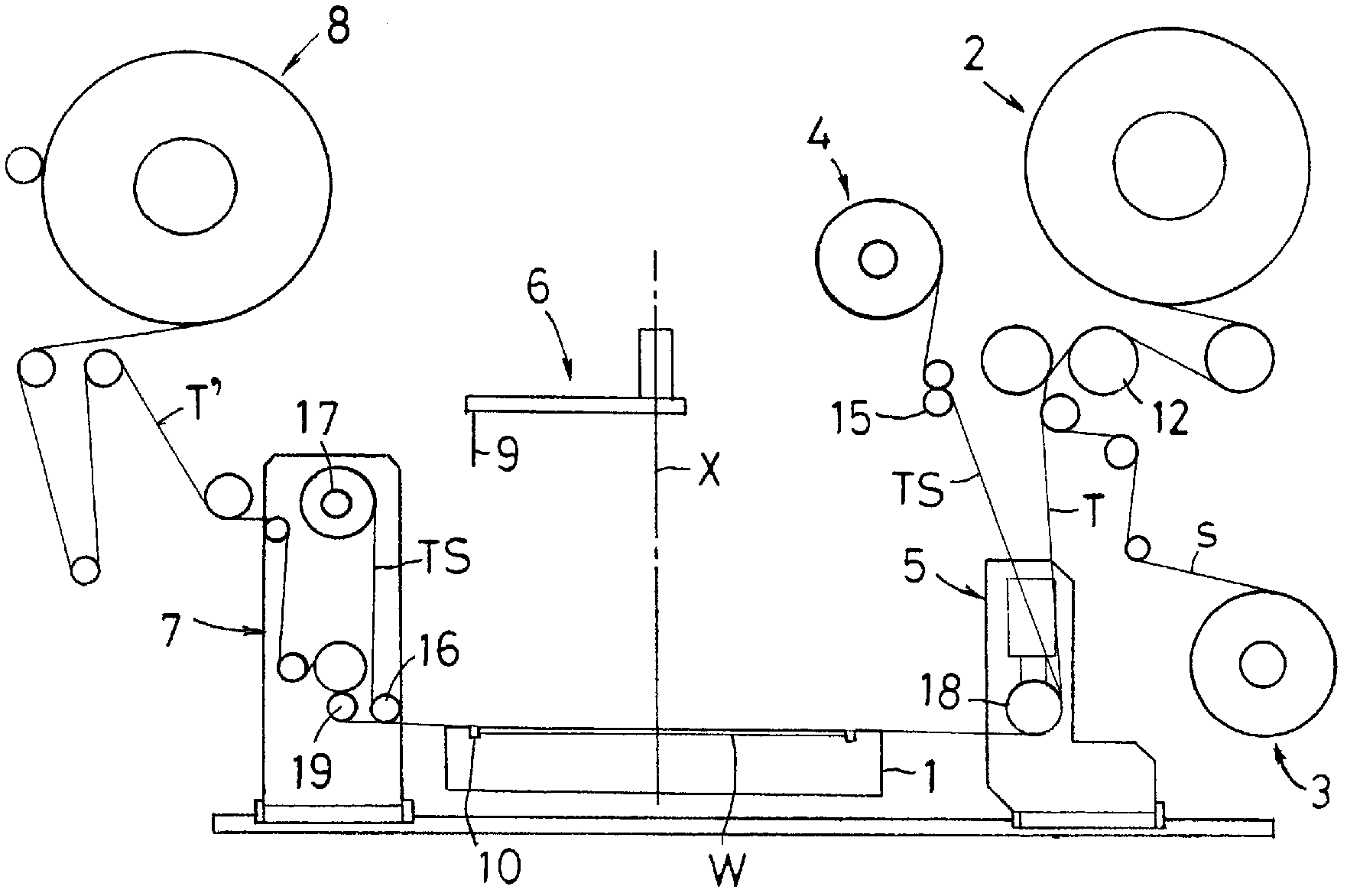

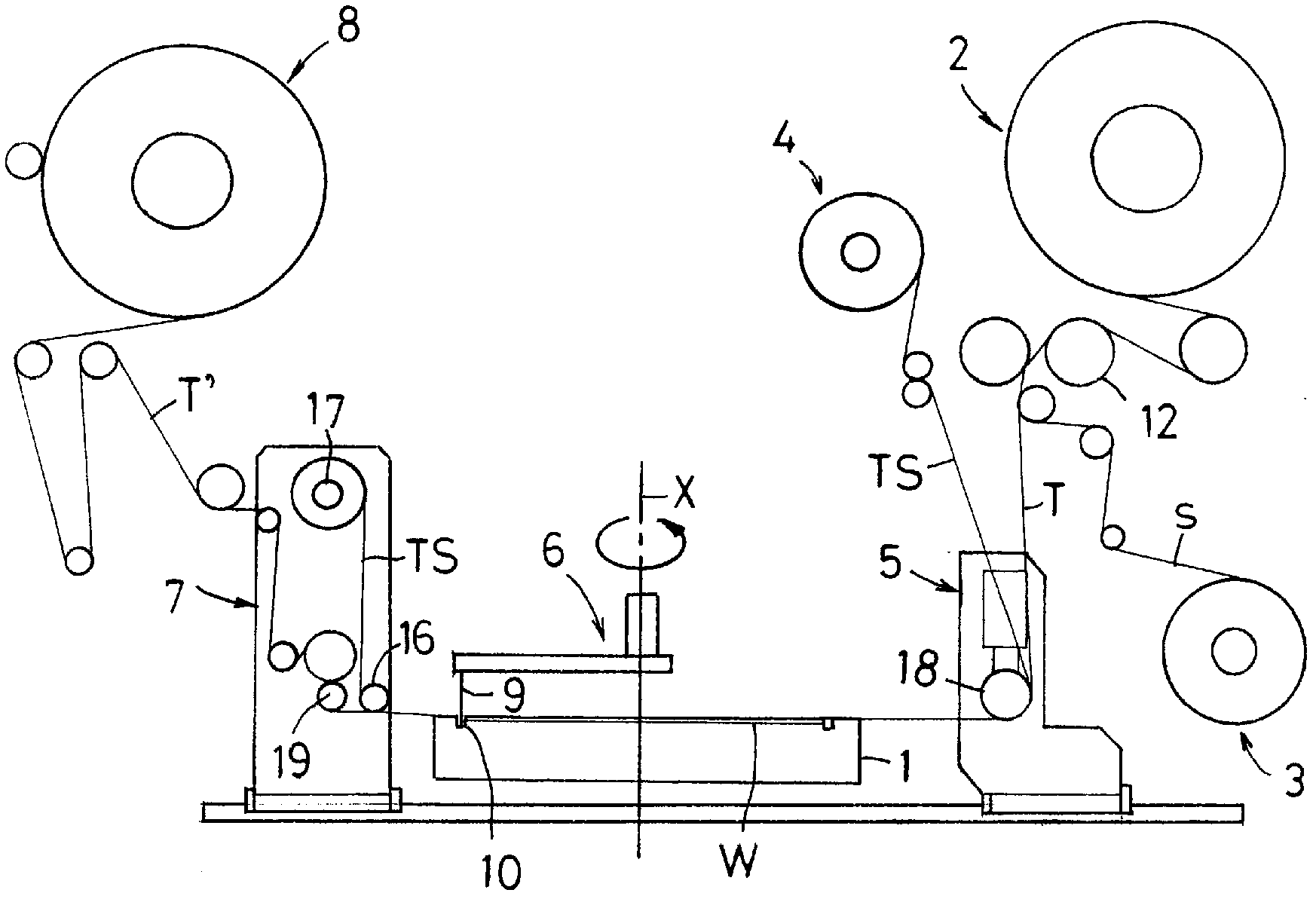

[0055] Hereinafter, an embodiment of the present invention will be described with reference to the drawings.

[0056] Figure 1 to Figure 4 The schematic structure of the protective tape sticking apparatus and the protective tape sticking process which carry out the method of this invention are shown in .

[0057] This protective tape sticking device has a chuck table 1 for placing and holding a semiconductor wafer W (hereinafter, simply referred to as "wafer W") by suction, and supplies wafers W held on the chuck table 1 with The tape supply unit 2 for the protective tape T for front protection, the release film recovery unit 3 that peels and recovers the release film s from the protective tape T with the release film s supplied from the tape supply unit 2, along the protective tape T The sheet supply part 4 that supplies the upper surface of the intermediate sheet TS, the sticking unit 5 that sticks the protective tape T on the wafer W sucked and held on the chuck table 1, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap