Extruded resin sheet manufacturing method and extruded resin sheet

A manufacturing method and resin board technology, which is applied in the field of extruded resin boards, can solve the problems of reduced retardation value, uncontrollable range, and reduced retardation value of resin boards, and achieve good surface properties, resistance to heating processes, and occurrence of warpage inhibitory effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0262] (Manufacturing method of extruded resin sheet)

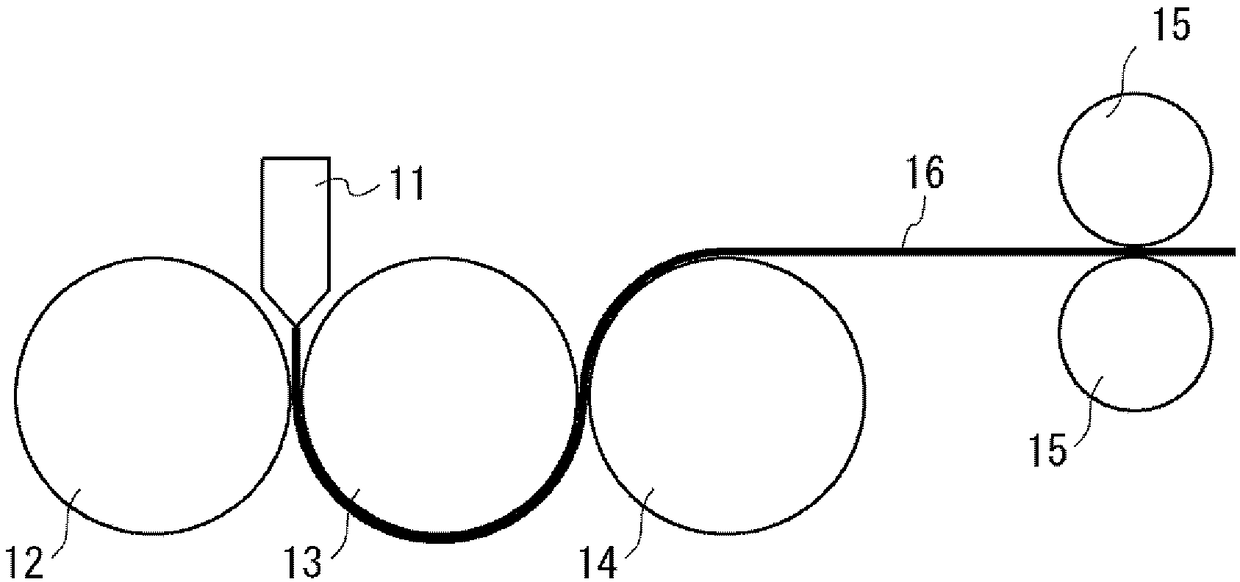

[0263] A methacrylic resin B (glass transition temperature: 120 degrees, linear expansion coefficient: 7.30×10 -5 / K) Melting with a 65mmφ single-screw extruder [manufactured by Toshiba Machine Co., Ltd.], melting polycarbonate with a 150 mmφ single-screw extruder [manufactured by Toshiba Machine Co., Ltd.], and laminating the two through a multi-manifold type die . The laminated resin (extruded resin sheet 16, thermoplastic resin laminate in molten state) is sandwiched between figure 1 Between the shown first cooling roll 12 and the second cooling roll 13, after being wound on the second cooling roll 13, it is wound on the third cooling roll 14, thereby cooling is carried out, and the extrusion The resin plate 16 is drawn away to manufacture an extruded resin plate. The resin temperature (TT) was adjusted to 150° C. by controlling the temperatures of the second cooling roll 13 and the third cooling roll 14 . In addit...

Embodiment 2~4

[0265] Instead of methacrylic resin B having a TC ratio of 20% by mass, the methacrylic resin B having a TC ratio described in the column "Methacrylic resin-containing layer" of Table 2 was used, and the resin temperature (TT) was set as Except having adjusted as described in Table 2, it carried out similarly to Example 1, and produced the extruded resin board. Table 2 shows the production conditions and the evaluation results of the obtained extruded resin sheets.

Embodiment 5

[0267] An extruded resin sheet was produced in the same manner as in Example 1 as described in Table 2, using a resin composition (1) having an SMA ratio of 20% by mass instead of the methacrylic resin B having a TC ratio of 20% by mass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com