Method for testing shading baffle of photo-etching machine

A technology of lithography machine and light-shielding plate, which is applied in micro-lithography exposure equipment, originals for photomechanical processing, optics, etc., and can solve the problem of not being able to find out whether there is a defect in the mask plate light-shielding plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

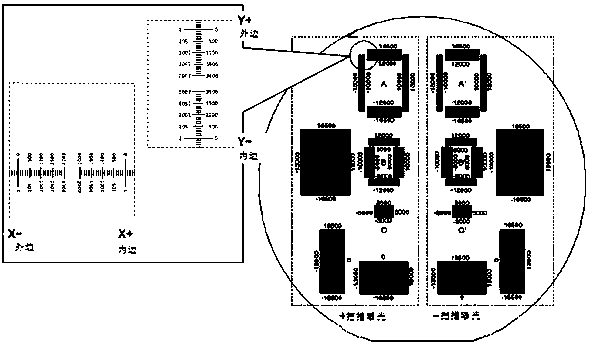

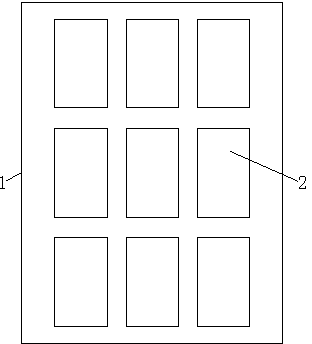

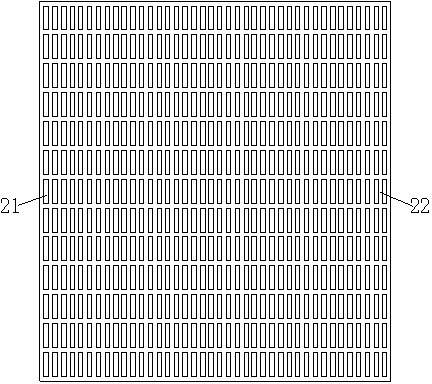

[0031] figure 2 It is a schematic diagram of the layout structure of the test image on the test template in the method for testing the shading baffle of the photolithography machine in the present invention; image 3 It is a structural schematic diagram of an enlarged test image in the method for testing the shading baffle of a photolithography machine according to the present invention. Such as figure 2 , 3 As shown, the present invention is a method for testing the shading baffle of a photolithography machine:

[0032] First, after completing the standard mask mask test, confirm that the mask mask mask has met the basic accuracy requirements.

[0033] Secondly, a binary mask (BinaryMask) or a phase shift mask (PhaseShiftMask) is used as the test mask 1, and a rectangular test image 2 is set on it, and the test image 2 consists of a plurali...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com