Braking device of jig dyeing machine

A braking device and dye jigger technology, applied in the field of dye jiggers, can solve problems such as excessive tension, cloth congestion, difficulty in properly applying frequency conversion technology, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

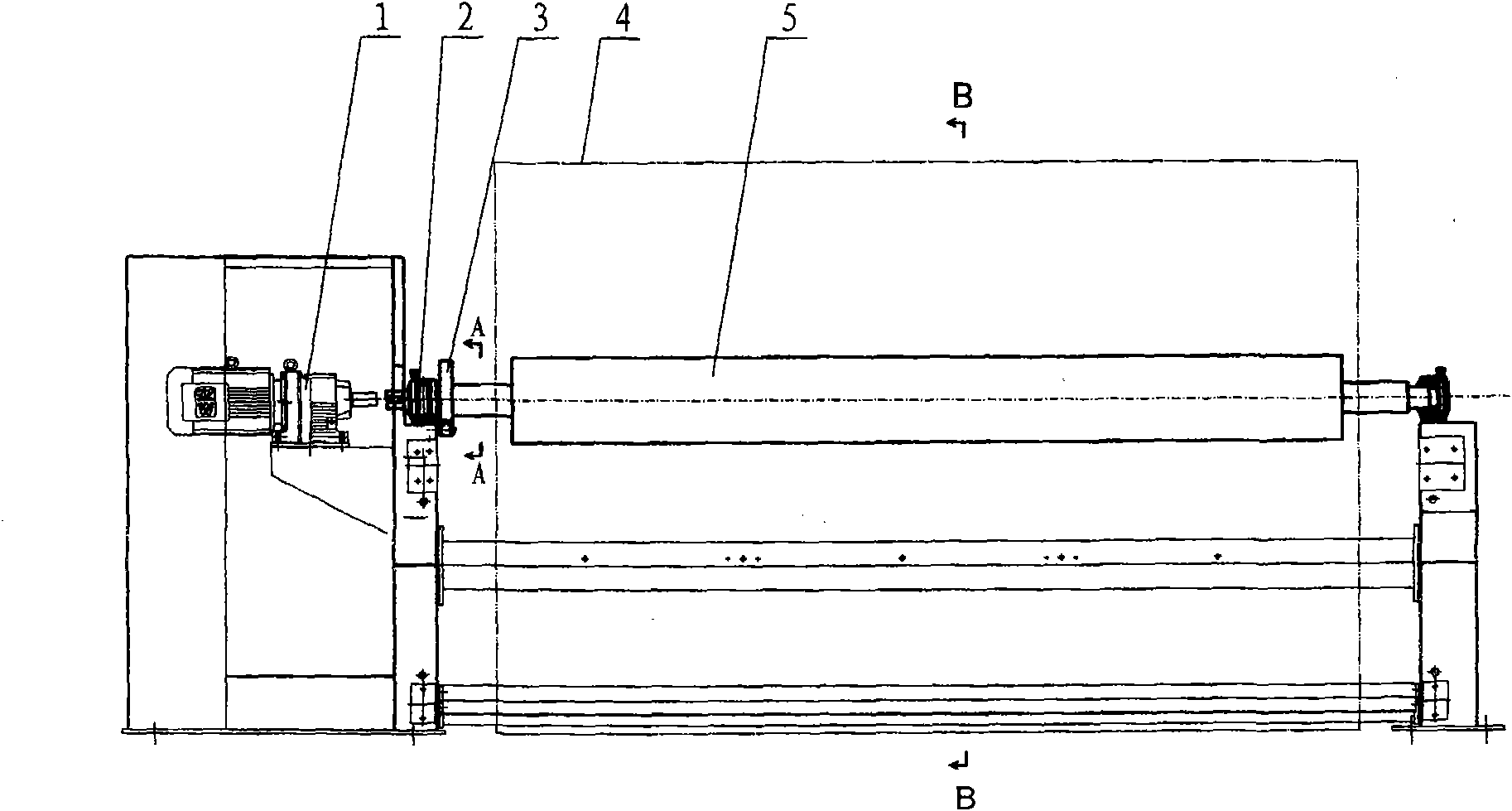

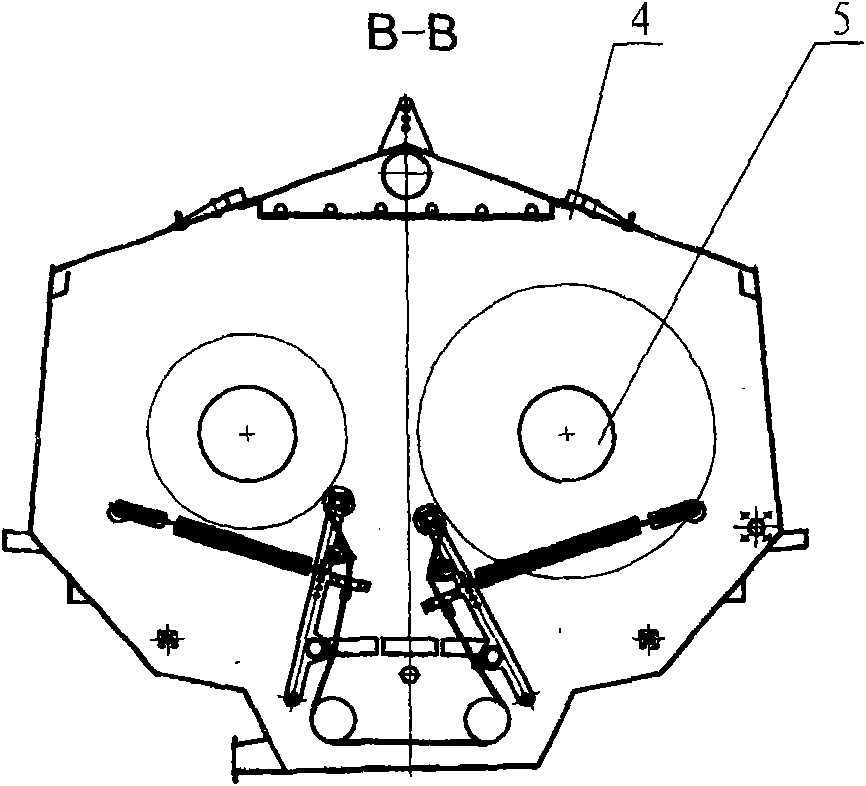

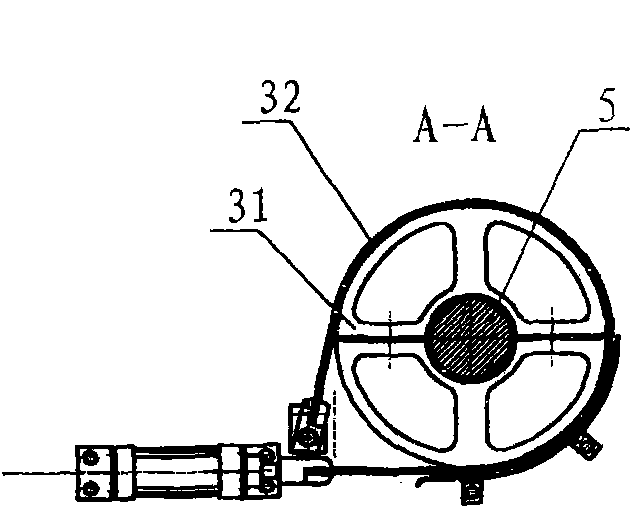

[0014] The present invention is as Figure 1-4 As shown, the jigger includes a motor reducer 1, a frame 2, a cover body 4, and a pair of cloth winding rollers 5 arranged horizontally on the frame 2, and it also includes a controller and a braking device 3; the system The driving device 3 includes a braking hub 31, a braking band 32 and a pneumatic driving device for driving the braking band 32, the pneumatic driving device is connected to the controller; the braking hub 31 is arranged on the roller head 51 of the cloth winding roller One end of the braking band 31 is connected to the frame 2 through a hinge shaft 33 .

[0015] The pneumatic drive device includes an air source, a cylinder 61, a flow control valve 1 62, a flow control valve 2 63 (with a rod cavity and a rodless cavity respectively), an electromagnetic reversing valve 64 and a pressure reducing valve 65. , the pressure reducing valve 65, the electromagnetic reversing valve 64, the flow control valve 1 62, the fl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap